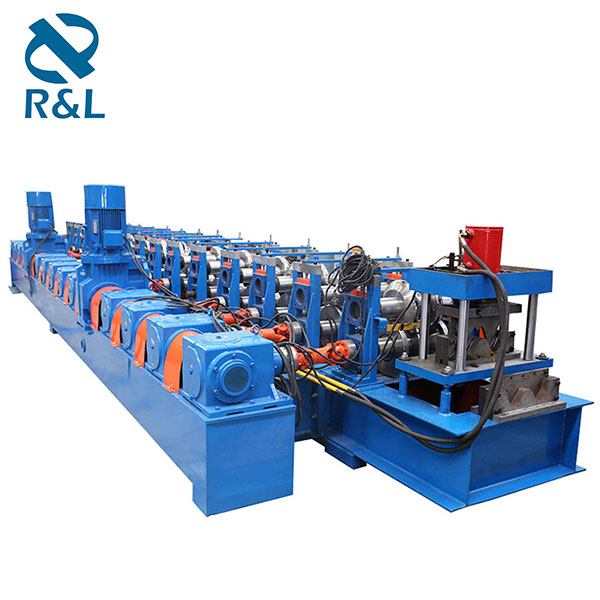

Highway Guardrail Roll Forming Machine

Description

Introduction:

As a manufacturer located in China, we are pleased to offer our new product – the Highway Guardrail Roll Forming Machine. This machine is designed to create high-quality guardrails for various highways, roads, and bridges. It is an efficient and cost-effective solution that can contribute to safer transportation systems.

In this product introduction, we would like to highlight the features and benefits of our Highway Guardrail Roll Forming Machine. We will also explain the technical aspects and specifications of the machine to help merchants understand how it works and how it can be used to produce high-quality guardrails.

Features and Benefits:

Our Highway Guardrail Roll Forming Machine is designed with several features and benefits that can attract merchants. The following are some of the key aspects:

1) High Efficiency: The machine can produce guardrails with high precision, speed, and consistency. It can produce up to 15 meters of guardrails per minute, which means it can produce large quantities of guardrails in a short time.

2) Easy Operation: The machine is easy to operate, and it requires minimal training. It comes with a user-friendly interface and instructions that guide the operator through the entire process.

3) Durable: The machine is made of high-quality materials and components that ensure its durability and longevity. It is designed to withstand harsh environmental conditions and severe weather.

4) Low Maintenance: The machine requires minimal maintenance and can function 24/7 without any significant downtime. It has a self-diagnostic function that can identify any issues and fix them automatically.

5) Energy Saving: The machine is designed with energy-saving features that reduce its power consumption and lower the operating costs.

Technical Aspects:

Our Highway Guardrail Roll Forming Machine is a complex piece of machinery that can produce high-quality guardrails with precision and accuracy. The following are the technical aspects of the machine:

1) Material Type: The machine can use a variety of materials to produce guardrails, including hot-rolled steel, galvanized steel, and aluminum.

2) Cutting Mechanism: The machine uses a hydraulic cutting mechanism to cut the guardrail to the desired length. It can cut the guardrail with precision and speed.

3) Forming Process: The machine uses a roll forming process to shape the guardrail into the desired shape and size. It can create various types of guardrails, such as W-beam, thrie-beam, and box-beam guardrails.

4) Control System: The machine is controlled by a computerized system that regulates the speed, pressure, and temperature of the machine. It also has safety features that protect the operator and the machine from any accidents.

Conclusion:

Our Highway Guardrail Roll Forming Machine is an innovative and efficient solution for producing high-quality guardrails for various transportation systems. It is easy to operate, durable, low maintenance, energy-saving, and can produce large quantities of guardrails with precision and accuracy.

We believe that our product can benefit merchants who are looking for a reliable and cost-effective solution for producing guardrails. We welcome interested merchants to contact us to learn more about our product, pricing, and shipment options.

Introduction

This Highway Guardrail Roll Forming Machine specializes in producing all kinds of highway guardrail products, which are widely used in highways and related fields. It has the advantages of fast production speed, online punching and continuous molding production, and can produce high-strength products and meet your requirements for materials and dimensions. At the same time, its computer control system is sensitive and adjustable, which will help you operate more easily and reduce personnel costs. If you have special requirements, please contact us and provide detailed parameter information to communicate more detailed production details.

Features

The main parts of the Highway Guardrail Roll Forming Machine are made of high-quality steel, and the surface has been specially treated to make it durable and not easy to rust and corrode. Its structure is simple and compact, which can ensure quick and simple installation, so as to put into production as soon as possible and help you effectively improve processing efficiency. In addition, its easy-to-learn man-machine interface and PLC control panel will allow you to adjust and assist the machine to produce ideal product specifications to meet the application needs of various industries.

|

Hydraulic de-coiler with 2 heads Coil ID: 550 ~ 780mm; Width of the coil: 150 mm - 580mm; Hydraulic station power: 7.5KW; Max Load: 5 T; Qty: 1PC;

|

|

|

Feeding - Leveling and counting It is used for making the material flat before feeding it into the roll-forming machine. Entrance and guide roller: 7 rollers ( Up 3, down 4); Material GCr15, heat treatment; Frame: 400 H steel;

|

|

|

Pre punching device 100T hydraulic punching device; Piston hydraulic pump; Hydraulic station power: 11KW; 9 holes punching

|

|

|

roll forming machine Frame: 400 H steel with welded feeding platform; Roller stations: 15 stations; Roller material: Cr12; Diameter of main shaft:116mm; Material of the main shaft: #45 steel, quenching and tempering treatment; 230 type gearbox driving; Main machine power: 2*22KW; Frequency changer power: 50KW; Speed: 8m/min (including punching and cutting); "W" shape forming;

|

|

|

Post cutting device Cutter material: Cr12; Power supply: hydraulic station shared with punching device; Frame: welding steel frame; Cutting pressure: 50T.

|

|

|

PLC Control System Control the quantity & punching length & cutting length automatically; The Machine will be stopped while it is punching and cutting; Automatic Length measurement and quantity counting (precision 3m+/- 2mm); Voltage: 380V, 3 Phase 50Hz (or as per buyer’s request);

|

|

|

Collection Table Function: Support and output the product; Structure: stand and supporting roll; Size: L 3m x W 0.5m; Qty: 2PCS.

|

|

FAQ

1. Q: If I need to visit your company for a few days, can you book a hotel for me?

A: I have always been happy to provide hotel reservations.

2. Q: What is your minimum order quantity, can you send me a sample?

Answer: Since our products are mechanical equipment, our minimum order quantity is 1 set, it is difficult to send you samples, however, we can send you product catalogs and warmly welcome you to visit our company.

3. Q: Is it possible to customize the machine as required, such as put our logo on it?

A: Of course our machines can be customized according to your needs, and your logo can also be affixed.

4. Q: How to ensure that the machine will not be damaged due to the long shipping time?

Answer: Our machines will be packaged in professional packaging, which can properly protect the product from damage during long-distance transportation.

5. Q: May I know which payment your company accepts?

A: So far, we can offer 100% T/T before shipment, and 30% deposit paid by T/T, and the balance paid by L/C.

6. Q: Regarding after-sales service, how do you solve the problems encountered by overseas customers in a timely manner?

A: The warranty period of our machines is usually 12 months, during this period, we will arrange international express immediately to ensure the replacement parts as soon as possible.

7. Q: Will you arrange the installation of the machine at present after we place the order?

A: All machines will be well tested before delivery, so almost all machines can be used directly, and our machines are very easy to install.

Why choose us?

- We offer quick and efficient delivery of our products to reduce downtime and increase productivity.

- Our company follows the policy of 'establishing an image by management, and winning the market by quality', carefully builds our brand, and serves every customer wholeheartedly.

- Our products are built to last and withstand rigorous use.

- Our products have been put into the domestic and foreign markets and are recognized by the majority of businesses and consumers.

- Our machines are manufactured using the latest technology and advanced techniques.

- Our company with its strong technical force, advanced equipment, unique design concept, keep improving, product style is novel and diverse, unique.

- Our machines are designed to reduce labor costs and increase efficiency.

- We are responsible for every process of our Highway Guardrail Roll Forming Machine and go all out to continuously improve product quality.

- Our metal roll forming machines are designed to be highly efficient and reduce production costs.

- Our products occupy the unique market with absolute advantages in terms of value and quality, and have won the trust of our customers.

Hot Tags: highway guardrail roll forming machine, Glazed Tile Roof Sheet Roll Forming Machine, Shutter Door Forming Machine, Rolling Shutter Making Machine, Multi Rib Span Roof Sheet Roll Forming Machine, Self Lock Roof Panel Roll Forming Machine, C Section Rollformer