Automatic Trunking Cable Tray Machine

Description

Introduction

If you are in the construction or electrical industry, then you know how important it is to have the right equipment to get the job done efficiently and effectively. One such piece of equipment that can significantly improve your productivity is the Automatic Trunking Cable Tray Machine. In this article, we will explore the various aspects of this product and how it can benefit you in your business.

What is the Automatic Trunking Cable Tray Machine?

The Automatic Trunking Cable Tray Machine is a machine designed to manufacture cable trays in a fully automated process. Cable trays are used to support and protect electrical cables and wires, making them an essential component in the electrical and construction industry. With the Automatic Trunking Cable Tray Machine, you can create cable trays in a variety of sizes and materials with ease.

Key Features of the Automatic Trunking Cable Tray Machine

1. Fully Automated Process: The Automatic Trunking Cable Tray Machine is an entirely automated process. This means that you can create cable trays with minimal human intervention, reducing labor costs and increasing productivity.

2. Versatile: The machine can create cable trays in a wide range of materials, including stainless steel, aluminum, and galvanized steel. Additionally, it can create trays in various sizes, making it an excellent option for any project.

3. High-Quality Output: The Automatic Trunking Cable Tray Machine produces high-quality cable trays with consistent dimensions and appearance. This means that you can ensure that your customers receive a top-quality product each time you use the machine.

4. Easy to Operate: The machine is easy to operate, making it an ideal option for businesses of all sizes. It requires minimal training to operate, and you can create cable trays quickly and efficiently.

Benefits of Using the Automatic Trunking Cable Tray Machine

1. Cost-Effective: The fully automated process of the Automatic Trunking Cable Tray Machine means that you can reduce labor costs significantly. Additionally, it produces high-quality trays, which will save you money on replacing faulty products.

2. Increased Productivity: With an automated process, the Automatic Trunking Cable Tray Machine can create cable trays quickly and efficiently, increasing your overall productivity.

3. Versatile: The machine can create cable trays in a wide range of materials and sizes, making it a versatile option that can handle any project.

4. High-Quality Output: The Automatic Trunking Cable Tray Machine produces high-quality cable trays with consistent dimensions and appearance. This will ensure that your customers receive top-quality products, increasing customer satisfaction and retention.

Conclusion

In conclusion, the Automatic Trunking Cable Tray Machine is a versatile and cost-effective option for businesses in the construction and electrical industry. With its automated process, the machine can significantly reduce labor costs while increasing productivity. It can create cable trays in a wide range of materials and sizes, ensuring that it is a versatile option that can handle any project. Furthermore, the high-quality output of the machine will help you build a reputation for producing top-quality products, increasing customer satisfaction and retention. Consider investing in the Automatic Trunking Cable Tray Machine to take your business to the next level.

Introduction

The Automatic Trunking Cable Tray Machine is controlled by PCL program, so the reaction speed is fast and sensitive. The machine body is made of high-quality steel by precision welding. The machine has high automation degree, good performance, but low cost, so it has good cost performance. The machine has two operation methods, automatic control and manual control, to meet different working environments. It is also equipped with an emergency stop device to ensure the safety of the operator. The surface is treated, so it is not easy to rust.

Features

1. All lines are wrapped with insulating materials to avoid accidents.

2. There are a variety of specifications and models, which can also be customized to meet customer needs.

3. Automatic Trunking Cable Tray Machine is highly automated, so it is easy to operate.

4. All products are subject to strict quality inspection, so the quality is guaranteed.

Products Details

1. Decoiler: 1 set

Capacity: 5000kg

Width: 600mm

Inner Diameter: 450-550mm

Outer Diameter: 1500mm

Type: Hydraulic or Manual (optional)

2. Cutting System: 1 set

Type: Hydraulic Cutting

Power: 7.5kw

Material for cut-off modular: Cr12 steel after treatment

Driven: 1.5-inch chain

3. Roll Forming: 1 set

Roller material: cold rolled steel sheet

Material thickness: 1-2mm

Rollers: 22 groups

Material for rollers: GCr15 steel after treatment

Hardness for heat treatment: HRC 58-62

Frame: panel thickness: 20mm

Bottom frame: 40# H-section steel

Motor power: 11kwx2

4. Control System: 1 set

Type: PLC frequency control system with

Encode Brand: Omron

Length error: +/-2mm

5. Hydraulic Pump: 1 set

Power: 3kw

Oil type: 3kw

Oil type: 46# hydraulic oil

Pump Brand: China brand

6. Output Table: 1 set

|

Quantity of forming rollers stations |

About 22-24 stations |

|

Diameter of forming rollers shafts |

90mm |

|

Roll forming speed |

10-15m/min |

|

Production speed |

4-6m/min |

|

Forming rollers material |

GCr15 mould steel, with quenched treatment |

|

Cutter material |

Cr12 mould steel with quenched treatment |

|

Control system |

Panasonic PLC and Yaskawa converter |

|

Electric power requirement |

Main power: 4x5.5kw |

|

Hydraulic unit power: 5.5kw |

|

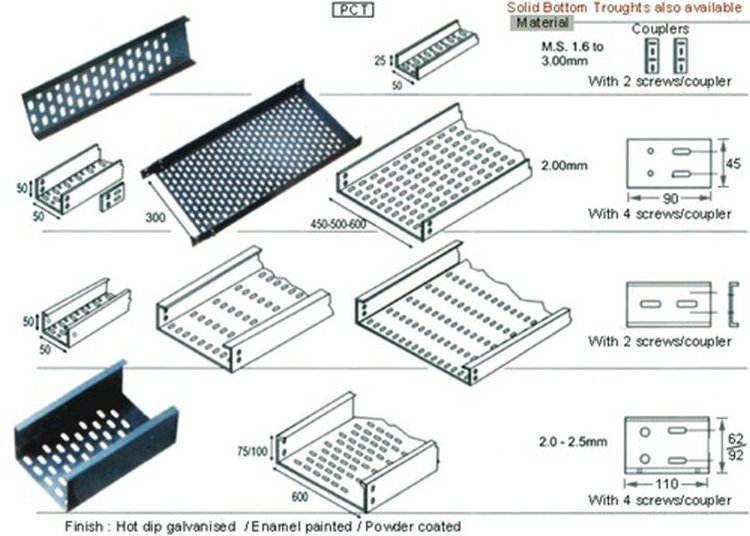

Profile Drawing

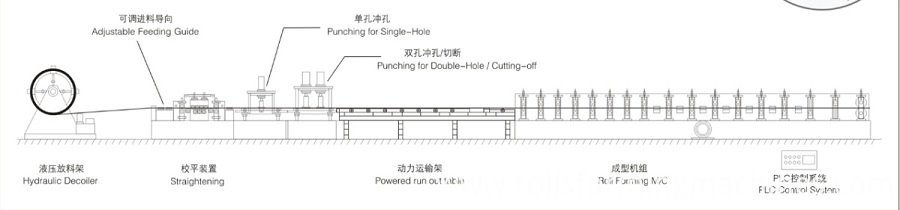

Process drawing

Why choose us?

- We offer comprehensive training and support to ensure customers can effectively operate our machines.

- We are honest and trustworthy with suppliers and sellers, and safeguard the interests of the company and the rights of stakeholders.

- Our machines are easy to use and require minimal maintenance, saving our customers time and money.

- Our company is committed to the trust and support of our customers and partners, and today we have developed into a certain scale and strength of enterprises.

- We offer quick and efficient delivery of our products to reduce downtime and increase productivity.

- Our company's Automatic Trunking Cable Tray Machine has won the trust and praise of customers with high precision, reliable quality, reasonable price, short production cycle other competitive advantages.

- Our machines are versatile and can be used to produce a wide range of products.

- We persevere in the development of technological innovation, integrate the most advanced technology into our product production, and strive to create perfect Automatic Trunking Cable Tray Machine.

- We specialize in producing Metal Roll Forming Machines of the highest quality.

- The fundamental way out for enterprises to face complex situation and fierce competition lies in innovation.

Hot Tags: automatic trunking cable tray machine, Corrugated Roof Sheet Roll Forming Machine, Deck Roll Forming Machine, Corrugated Sheet Making Machine, Purlin Roll Former, Iron Sheet Corrugated Making Machine, Rollfomer