Wider Rolling Shutter Door Panel Roll Forming Machine

Description

Introducing the Wider Rolling Shutter Door Panel Roll Forming Machine from our manufacturing plant in China.

As a leading manufacturer of cutting-edge and high-performance machinery, we take immense pride in introducing our Wider Rolling Shutter Door Panel Roll Forming Machine. This product is designed to offer maximum efficiency and productivity in the manufacturing of high-quality Rolling Shutter Door Panel Roll Forming systems. Our machine is reliable, low-maintenance, and budget-friendly, making it an ideal choice for merchants looking for a machine that boosts their productivity and saves time and money.

Here are some standout features of our Wider Rolling Shutter Door Panel Roll Forming Machine.

1. High Accuracy Rollforming

Our machine is designed with precision engineering that ensures perfect and high-quality rolling shutter panels. The machine has variable speed control that allows for custom settings at different levels, ensuring that you get the exact size and thickness of the door panels you need.

2. Durability and Stability

Our machine is made with high-grade material and advanced technology that guarantees durability and stability, even with long hours of continuous operation. The sturdy and robust structure of our machine facilitates high-quality output with minimal downtime.

3. User-Friendly Controls

The user-friendly design means that you do not need to be an expert to operate this machine. It comes pre-configured with easy-to-use controls that allow you to adjust the settings for your desired panel thickness, speed, and size. The controls allow you to program, monitor and control the entire process, ensuring that your workflow is smooth and seamless.

4. Minimal Maintenance

Our Wider Rolling Shutter Door Panel Roll Forming Machine is low-maintenance, thanks to its advanced technology and durable components. The machine requires minimal service, ensuring that your production processes will not be interrupted by regular maintenance requirements.

5. Cost-Effective

Choosing our Wider Rolling Shutter Door Panel Roll Forming Machine allows you to increase your production capacity while reducing your production costs. Our machine's advanced technology enables high-quality output with minimal wastage, reducing costs while boosting efficiency and productivity.

In conclusion, our Wider Rolling Shutter Door Panel Roll Forming Machine offers advanced technology and high-grade components that guarantee durability, stability, and cost-effectiveness. This machine is the perfect investment for merchants looking to enhance their production capacity and save more on production costs. Get in touch with us today and discover what our Wider Rolling Shutter Door Panel Roll Forming Machine can do for your business.

Introduction:

The Wider Rolling Shutter Door Panel Roll Forming Machine is equipment for the production of rolling shutter panels. The widened rolling shutter door panel forming machine processes the steel plate through a series of processes and presses it into a roll-shaped door panel. Commonly used in commercial, industrial and residential applications, they produce strong, durable and aesthetically pleasing roller blinds that protect buildings from theft, fire and other security threats. Secondly, our products are usually composed of multiple components, including rolling door forming machines, automatic cutting machines, painting machines, rolling door rolling machines, etc., which together complete the entire production process of rolling door panels. Finally, if you have any questions about our products, please feel free to ask us!

Feature

The Wider Rolling Shutter Door Panel Roll Forming Machine is mainly composed of feeding platform, forming machine, forming and shearing device, hydraulic station, computer control system and other parts, and are used in conjunction with the sewing machine. It is widely used in the production of various industrial plants, warehouses, supermarkets and shopping malls. Secondly, our entire unit automation control system adopts a highly integrated network, which makes the performance of the automation system more superior. Finally, our products have the advantages of easy operation, maintenance, maintenance, mechanical debugging, and easy mold replacement.

Advantage

High performance

No noise

Low cost

1 Years warranty

Long service life

Easy to operate

Full Automatic

Chain Drived

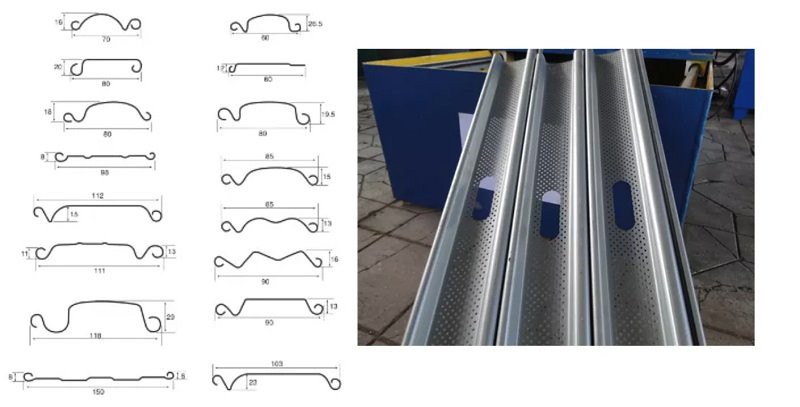

Drawing

In correct operation & maintaining, the machine is guaranteed for one year since the machine arrived at clients’ factory.

Installation:

If installation is needed, the buyer shall make the following preparation before arrival of technicians.

a) Position the machine in the buyer’s factory.

b) Prepare necessary electric wiring.

c) Prepare material of trial running.

d) Provide labors for assistance and installation during installation.

e) If possible, One Chinese-speaking interpreter so that the communication between the buyer and seller’s technician will go smoothly.

Delivery

For the roll forming machine, before loading to the container, we will paint the anti rusty oil on the roller and shaft.

The easy damage parts will be packaged by the plywood or the bubble paper so that the machine will be not rusty or corrosion, and protect the machine very well during the period on sea.

One 20GP container can load two sets of the shutter door panel machine, and save much space in the workshop.

Why choose us?

- We offer comprehensive training and support to ensure customers can effectively operate our machines.

- We continue to improve our innovation capability and promote the development of the enterprise to a new situation through the "two-wheel drive" of technological innovation and model innovation.

- Our machines are customizable to meet specific requirements, delivering tailored solutions to our customers.

- We always adhere to the company's tenet of people-oriented, faithful and sincere, rigorous and efficient, realistic and innovative.

- We are dedicated to delivering the highest quality products and services to our customers.

- The core motivation of our business survival is to actively innovate in technology, service, management and operation to achieve differentiated advantages.

- We provide excellent after-sales service to ensure customer satisfaction.

- We are engaged in this Wider Rolling Shutter Door Panel Roll Forming Machine industry that has the vitality for long-term sustainable development.

- Our machines are easy to operate and maintain, reducing downtime and increasing productivity.

- Welcome new and old customers to come, write to us to discuss business, sincerely cooperate, we will work with you to create a better future.

Hot Tags: wider rolling shutter door panel roll forming machine, Multi Rib Span Roof Sheet Roll Forming Machine, Sheet Metal Forming Machines, Metal Tile Sheet Making Machine, Metal Roof Forming Machine, Closed Type Floor Decking Roll Forming Machine, Corrugated Roof Sheet Roll Forming Machine