Corrugated Forming Machine

Description

As a manufacturer based in China, we are proud to present one of our most innovative products: the Corrugated Forming Machine. This machine is revolutionizing the way corrugated materials are produced, offering merchants around the world a powerful and cost-effective solution to their manufacturing needs.

At its core, the Corrugated Forming Machine is designed to create high-quality corrugated materials with speed, precision, and consistency. By leveraging cutting-edge technology and unparalleled manufacturing expertise, our team has developed a machine that is capable of producing corrugated sheets or boxes of varying sizes, shapes, and styles to meet the needs of merchants operating in a wide range of industries.

One of the key features of the Corrugated Forming Machine is its versatility. Whether you need to produce plain, double-sided, or triple-layered corrugated materials, our machine can do it all. It can handle materials of varying thicknesses, from lighter materials like paper to more heavy-duty materials like cardboard. It can also accommodate a variety of corrugated designs, from the classic flute pattern to innovative and custom designs.

But versatility is just one part of the story. What truly sets the Corrugated Forming Machine apart is its precision and quality. With advanced automation systems and precise controls, we ensure that every corrugated material produced is of the highest possible quality. The machine also ensures that the materials have a uniform thickness, shape, and size, eliminating any chances of error or inconsistency.

Another significant benefit of the Corrugated Forming Machine is its speed. The machine can produce a high volume of corrugated materials in a short amount of time, making it ideal for merchants who need to operate on tight schedules. Additionally, this high-speed production does not compromise on quality or precision.

We also understand that merchants need a cost-effective solution to their manufacturing needs, which is why we have designed the Corrugated Forming Machine to be not only affordable but also energy-efficient. The machine's innovative design helps minimize energy consumption and waste, reducing its impact on the environment and helping merchants save money in the long run.

At our manufacturing facility, we are committed to producing machines that are not only functional and efficient but also safe and easy to use. Our team rigorously tests each machine to ensure that it operates as smoothly and safely as possible. With intuitive panels and control systems, the Corrugated Forming Machine can be operated by anyone, without the need for specialized training.

To sum it up, the Corrugated Forming Machine is the ideal solution for merchants looking for high-quality yet affordable corrugated materials production. With its versatility, precision, speed, and energy efficiency, this machine can help your business operate more efficiently and cost-effectively. So why not contact us today to learn more about how the Corrugated Forming Machine can benefit your business?

Introduction

This corrugated forming machine is loved by many customers because of its high efficiency and high precision. It is specially designed to produce corrugated board or cartons of various shapes and sizes. The structure of the machine has been carefully designed and adjusted by our technicians to ensure the overall stability, and we have selected high-quality steel materials to provide high strength, high wear resistance and corrosion resistance. The automated control system can effectively reduce labor intensity and reduce dimensional errors in the actual application process, which helps to improve product quality and production efficiency. For corrugated cardboard manufacturers who are looking for a solution to shorten the construction period, this machine is undoubtedly an economical and effective production tool.

Features

1. This machine has a wide range of applications because it can efficiently produce corrugated cardboard or cartons for various industries.

2. The high-performance control system can effectively ensure the consistency of the product and increase the precision.

3. The operation process of this machine is very simple and easy to learn, so the operator can carry out practical operation without long-term training.

4. Every corrugated forming machine has passed our strict debugging and testing to ensure high performance and stability.

Specification:

1. With five rolls leveling structure to make the profile rolled smoothly when the strip was used as raw material.

2. Axle Diameter: 60mm

3. Line Speed: 0-15m/min

4. Roller Quenching Hardness: HRC58° — 60°

5. Rolling Thickness: 0.48mm

6. Rolling rod uses high quality alloy 45# steel galvanized

7. Wall frame material: 45# steel

8. Computer measuring the length: length scaling and accuracy: ±1.5mm

9. Length of Production Line: 5.5 m, with 16 stations to form.

10. Cutting Blade material: Cr12

11. Inverter: Dema Series

12. Computer PLC: Panasonic/Mitsubishi

13. Computer Control Panel: 7 inches color touch screen

14. Motor Power: 5.5KW Hydraulic Power: 3KW

15. Process Flow

Uncoiling --- Feeding --- Roll Forming (knurling) — Cut to Length --- Discharge

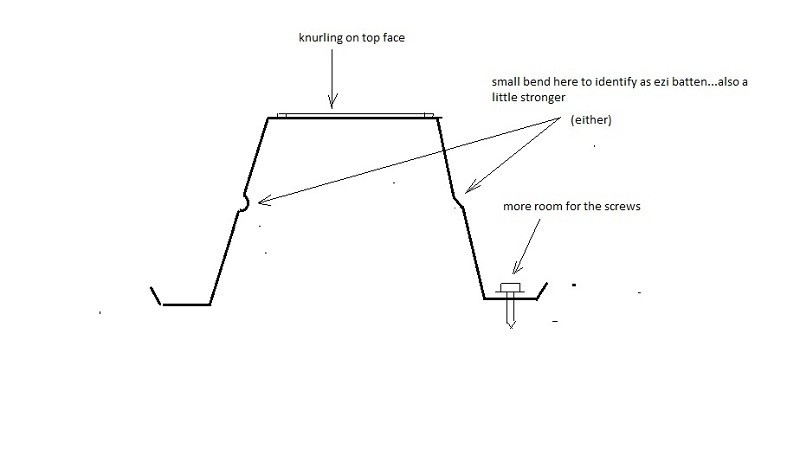

Profile drawing:

Why choose us?

- Our company has specialized in providing top-notch Forming Machines that meet the demands of our customers.

- We adhere to the customer-centered, quality-oriented and market-oriented business philosophy.

- We have a team of highly skilled professionals who are dedicated to delivering quality Forming Machines to our customers.

- Our company has produced many different Corrugated Forming Machine products for customers from different regions and countries and have received good reviews.

- Our Factory is based in China and we offer high-quality Forming Machines at reasonable prices.

- It is our hope that this employee and the company will grow together and create a win-win situation for both companies.

- Our Forming Machines are made of high-quality parts and components that are sourced from reputable suppliers.

- Our employees are our greatest asset, and we will strive to achieve mutual growth with our customers, employees, shareholders and all partners.

- As a leading supplier and manufacturer of Forming Machines, we deliver superior products and services.

- We uphold the style that everything starts from the practical, tough and practical work.

Hot Tags: corrugated forming machine, Double Layer Roll Former, Deck Roll Forming Machine, Downspout Pipe Roll Forming Machine, Floor Deck Roll Forming Machine, Roof Sheet Roll Forming Machine, Iron Roof Tile Making Machine