Corrugated Steel Water Tank Machine

Description

to showcase the benefits and features of my Corrugated Steel Water Tank Machine.

Introduction

As a manufacturer of high-quality industrial equipment based in China, we are proud to offer the Corrugated Steel Water Tank Machine to merchants in countries around the world. This machine is designed to produce large, durable corrugated steel water tanks quickly and efficiently, providing businesses with a reliable solution for their water storage needs. In this article, we will explore the benefits and features of our machine, and show you why it is an excellent investment for your business.

Features of the Corrugated Steel Water Tank Machine

The Corrugated Steel Water Tank Machine is designed to be easy to use, reliable, and efficient. Some of its key features include:

1. High-quality materials: Our machine is made from the finest quality materials to ensure it can withstand the harsh conditions of an industrial environment. It is built to last, with a heavy-duty frame, robust welding, and state-of-the-art electrical components.

2. Multiple sizes and shapes: We offer a variety of templates that enable merchants to produce a range of tank sizes and shapes. This feature puts our machine in a unique position as it allows users to create custom tanks to fit their specific needs.

3. Easy operation: The Corrugated Steel Water Tank Machine is a user-friendly device that requires minimal skill to operate. The machine comes with easy-to-follow instructions and as long as all safety protocols are followed, anyone can operate this machine.

4. High efficiency: Our machine can produce up to 1-2 tanks per hour, depending on the size and shape of the tank required. The speediness of the machine allows our users to be efficient in their production line and reduce lead times.

5. Low maintenance: The design of the machine is such that minimal maintenance is required. Our highly-skilled technicians have designed the machine to reduce downtime and maintenance costs, allowing our users to maximize their profits.

6. Cost-effective solutions: With our machine, businesses can save on costs associated with storage, transportation, and leakage. Produced on demand and on-site, water tanks built with our machine are a cost-effective solution without compromising on quality.

Benefits of the Corrugated Steel Water Tank Machine

1. Improved quality: The Corrugated Steel Water Tank Machine produces high-quality tanks that are both durable and resistant to corrosion. With high-quality production, our tanks are able to withstand even the harshest conditions in which they are placed.

2. Flexibility and adaptability: The machine is highly flexible and adaptable, enabling merchants to produce tanks of various sizes and shapes. This flexibility allows businesses to provide custom solutions for different customer demands, thus improving their competitiveness.

3. Time-saving device: The machine can produce up to 1-2 tanks per hour. This speed of production saves time, enabling businesses to increase their output and thus allowing them to take on more orders.

4. Cost-saving solutions: By producing water tanks on-site and on-demand, the Corrugated Steel Water Tank Machine saves on costs associated with transportation, storage, and leakage. Businesses can pass these savings to their customers while still maintaining high-quality standards.

5. Increased returns on investment: With the high efficiency of our machine, businesses can quickly recoup their investment costs and start generating profits. The durability and long-lasting nature of the tanks produced by our machine provide a long-term revenue stream for businesses.

Conclusion

In conclusion, the Corrugated Steel Water Tank Machine is a top-of-the-line piece of equipment that offers businesses a wide range of benefits. Its efficient speed of production offers businesses the ability to scale their production while reducing costs associated with tank storage and transportation. Our machine is flexible as we offer a variety of template shapes and sizes, allowing businesses to provide custom solutions for their customers. Finally, with its high-quality production, businesses can be assured of the durability and reliability of the water tanks produced. We stand behind our equipment with after-sale service and full technical support. If you are in the market for an industrial-quality water tank production machine, consider the Corrugated Steel Water Tank Machine for your business.

Introduction

The corrugated steel water tank machine is widely used, We purchase the main components from very famous company in China to ensure the performance of the equipment, we can also customize and design according to your specifications and outline drawings. In mountain orchards, hilly, rocky terrain growing areas, or water use areas in rural living areas, the terrain is generally more rugged, so additional water tanks may be required. The Corrugated Steel Water Tank Machine is the equipment specially used to produce this material, and the material it produces is an economical, environmentally friendly, fast, safe, and practical tank material.

Features

The Corrugated Steel Water Tank Machine is a highly automated production line. Its base is made of all-steel material, so it is very strong and can also allow the machine to run stably. Carbon steel materials and heat treatment can further enhance the strength and wear resistance of parts, and can also process materials with higher hardness. At the same time, the use of computer systems can further improve production accuracy. The cutting, stamping, and other processes of the product can be controlled automatically. In addition, our devices are all customizable, so they are versatile. And easy installation and operation features make the Corrugated Steel Water Tank Machine easier to use.

Machine Manufacturing Capability | |

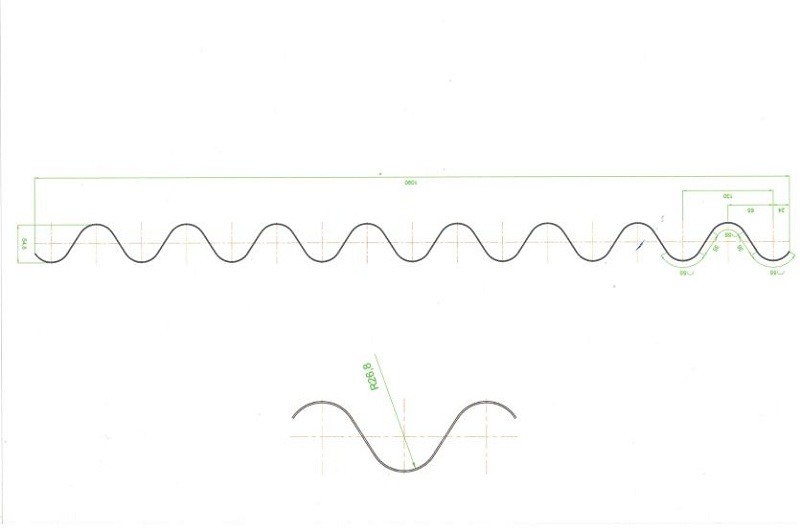

Profile | Corrugated shape, size designed according to customer request |

Sheet Thickness | 1.6mm – 3.3mm galvanized sheet by coil |

Main Parameters Of The Whole Production Line | |

Transmission | Chain wall plate |

Dimension | 12000mm (Length) x 1500mm (Width) x 1300mm (Height including cutting system) or 1000mm (Height without cutting system) |

Painting Color | Blue, green, yellow or upon customer request |

Main Parts | |

Driven Decoiler | Automatic hydraulic decolier |

Roll Forming | Structure: wallboard type structure (130mm thickness), entirety steel base, chain drive |

Main power: 22KW | |

Roller Station: 19. | |

Roller Material: GCr15 high carbon steel, Hardness HRC58 - 62° after heat treatment. We can change the material according to your request. | |

Roller Shape: designed through German design software COPRA | |

Curving | Can curve two-direction |

Can be integrated with the roll forming part, or stand alone | |

Curving radius adjustable from min. 1.5 meter up to whatever customer requests | |

Power: 2.2KW, or designed according to customer’s profile drawing. | |

Punching | Consists of gantry (upper & down board, and post), punching die, hydraulic oil cylinder |

Punch die is controlled by computer optically | |

Ball-lock style structure in order to install and exchange punching die easily | |

Cutting | Power: 3.5KW |

Collection Table | |

Hydraulic decoiler, equipped with skip car

Roll Forming

Punching

Curving

Cutting

Collection

Why choose us?

- We are constantly striving to exceed our customers' expectations and deliver exceptional value.

- We have been perfectly devoted to the design, R&D, manufacture, sale and service of hair products during 10 years of development.

- Our company culture is built on a foundation of integrity, honesty and mutual respect.

- We are committed to being an innovator in technology, products and services, always at the forefront of technology.

- Our reputation for quality and reliability is second to none.

- We're looking forward to your inquiries.

- With years of experience and expertise, we are confident in our ability to deliver top-quality products at affordable prices.

- We have stable and reliable Corrugated Steel Water Tank Machine that make users feel at ease, and the company's reputation and brand image are well-known in the industry.

- We are constantly innovating and developing new products to meet the needs of our customers.

- Our product design follows specialization, efficiency, intelligence and network.

Hot Tags: corrugated steel water tank machine, Metal Roll Forming Machine, Roof Sheet Rollformer with Gearbox Transmission, Steel Wall Angle Forming Machine, Multi Rib Span Roof Sheet Roll Forming Machine, Floor Deck Roll Forming Machine, Rollfomer