Downpipe Roll Former

Description

As a manufacturer of high-quality roll forming machines, we are proud to present the Downpipe Roll Former - a versatile and efficient machine designed for the production of high-quality rainwater downpipes. This state-of-the-art machine offers a range of features and benefits that make it an excellent investment for any merchant looking to expand their product offerings and satisfy customers with high-quality, durable products.

First and foremost, the Downpipe Roll Former is an easy-to-use machine that delivers consistent, reliable results. Its advanced technology and superior design ensure that every downpipe produced is of the highest possible quality, with precise dimensions and smooth, wrinkle-free finishes. The machine is also highly customizable, allowing merchants to produce downpipes of different sizes and materials to meet the needs of their customers.

One of the key advantages of the Downpipe Roll Former is its speed and efficiency. With a maximum speed of up to 30 meters per minute, it is capable of producing large quantities of downpipes quickly, which is essential for meeting customer demand and staying ahead of the competition. Additionally, the machine's smooth and efficient operation minimizes waste and reduces production costs, making it a highly economical choice for any business.

Another important benefit of the Downpipe Roll Former is its durability and longevity. Made from high-quality materials and engineered to the highest standards, this machine is built to last for many years, even with heavy use. It also requires minimal maintenance, which further reduces operating costs and increases productivity.

In addition to these practical benefits, the Downpipe Roll Former is also highly versatile and adaptable. It can be used to produce a wide range of downpipes, from basic models to more complex designs with intricate detailing. This makes it a valuable asset for businesses looking to cater to a broad range of customers and offer a diverse product range.

At our company, we take pride in our commitment to quality, innovation, and customer satisfaction. Our Downpipe Roll Former is no exception - it is a product that has been designed with the needs and requirements of our customers in mind. By choosing our Downpipe Roll Former, merchants can be assured that they are investing in a high-quality and reliable machine that will deliver excellent results time and time again.

To summarize, the Downpipe Roll Former is a top-of-the-line roll forming machine that offers a range of benefits for merchants looking to expand their product offerings and produce high-quality rainwater downpipes. With its speed, efficiency, durability, versatility, and ease of use, this machine is an excellent investment that will bring value to any business. We invite merchants to explore our product further and discover the many benefits it can offer to their operations.

Introduction

Downpipe Roll Former is mainly composed of an unwinder, guide frame, forming part, fixed-length cutting part, receiving table, electrical control cabinet, and other components. Roll-formed products have a longer service time than traditional PPC pipes and are not easy to age, so the entire project can be more unified and help improve the aesthetics of the entire product. It can also roll and bend the roll-formed downspout into connecting elbows so that the downspout and its bends can be connected seamlessly, so it is widely used. We have a lot of experience and you can contact us at any time.

Features

Downpipe Roll Former adopts welded steel frame, so it is very strong and not easy to deform. The state is also very stable during high-speed operation.

With chrome plating, the wear resistance and strength of the rollers have been significantly improved.

The high-precision molding design can reduce the loss during operation and can withstand high impact.

The PLC control system can further simplify the operation process of the Downpipe Roll Former and improve product accuracy.

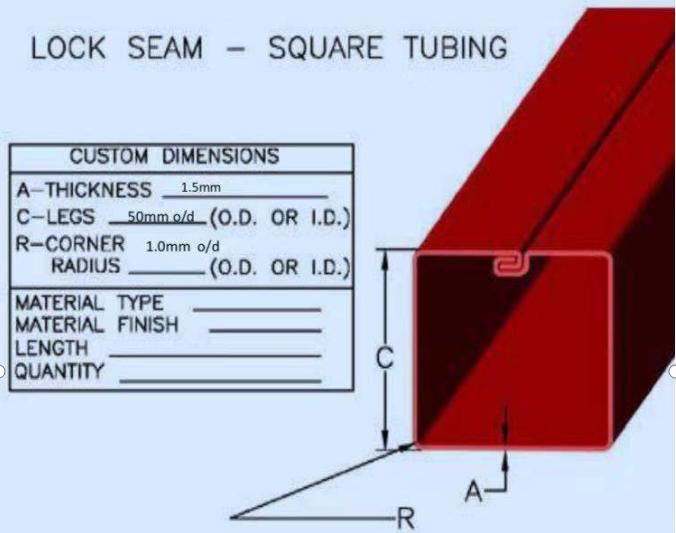

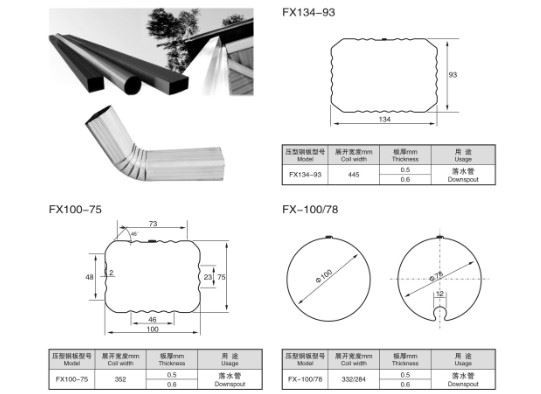

Profile Drawing

2. Equipment List

a. Decoiler*1 pcs

b. Roll Forming Machine*1pcs

c. Collection Table*1 pcs

3. Main Technical information

a. Decoiler: Passive, double support, Max loading weight: 3T

b. Unfold Width: up to the tube size

c. Thickness: 1.5mm

d. Forming Speed: 6-8m/min

e. Forming Station: 18

f. Frame: 36# I steel welded

4. Main Shaft

4.1 Material: GCr15

4.2 OD: 70mm

5. Roller

5.1 Material: GCr15

5.2 The single surface of Cr electroplating rollers: 0.05mm

6. Wall Thickness: 18mm

7. Transmission: chain

7.1 Name: bush roller chain

7.2 Model: 20A-1

7.3 Chain Material: high quality 45# steel

6.4 Heat Treatment: HRC45-50°

8. Motor: famous brand in China

8.1 Power: 7.5KW——1pcs

8.2 Original: China

8.3 Hydraulic Cutting, power: 2.2KW

9. PLC: Panasonnic

Why choose us?

- At our factory, we use only the highest quality materials and the most advanced manufacturing techniques.

- We set the goal of pursuing higher standards for our Downpipe Roll Former to create a better life for our customers and society.

- We are committed to minimizing our environmental impact and promoting sustainability in all of our operations.

- Over the years, professional companies from all over the world take us as their long-term and stable partners.

- Our company culture is built on a foundation of integrity, honesty and mutual respect.

- We establish and implement and strictly run quality and safety management system to effectively improve quality of the Downpipe Roll Former and service level.

- Our commitment to quality extends to our after-sales support and service.

- To become a world-class enterprise is the common vision and dream of all our employees, which requires the unremitting efforts of every employee.

- As both a supplier and a manufacturer, we offer competitive pricing on all of our products.

- Over the years, our company has been taking the route of independent research and development, guided by brand strategy, and based on technological innovation.

Hot Tags: downpipe roll former, Floor Deck Roll Forming Machine, Steel Silo Rollformer, Steel Silo Making Machine, Ibr Roof Sheet Forming Machine, Deck Roll Forming Machine, Metal Rollfomer