Chinese Roll Forming Machine

Description

Chinese Roll Forming Machine Introduction

Roll forming is a manufacturing process that involves continuously bending and shaping materials into desired shapes, sizes, and lengths. With advanced technology and innovation, roll forming machines have become a popular option for businesses all over the world.

Here at our company, we manufacture high-quality Chinese Roll Forming Machines that have gained a reputation in the market as reliable and efficient equipment. Our machines are designed to provide you with top-notch performance and an exceptional user experience, making them a perfect addition to any manufacturer's production line.

Benefits of Our Chinese Roll Forming Machines

Our machines are packed with several benefits that will benefit businessmen looking to add value to their manufacturing processes. Some of the benefits of our machines are outlined below:

1. Cost-Effective

Our Chinese Roll Forming Machines are affordable, making them an excellent option for suppliers who want to get the best deal while not compromising on quality. Our machines also have low maintenance costs, saving our clients' money in the long run.

2. High Accuracy

Our machines provide high accuracy when it comes to producing precision products. This makes them perfect for businesses that need consistent products at a high production rate.

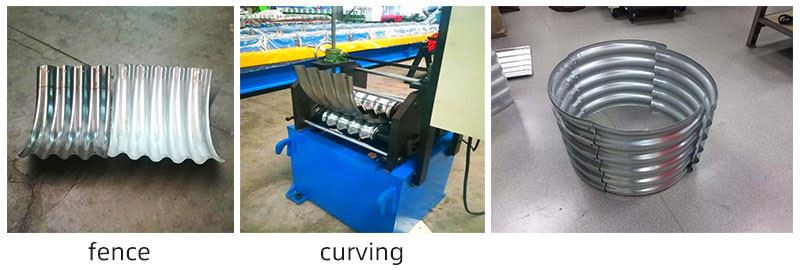

3. Versatility for Different Shapes

Our Chinese Roll Forming Machines are versatile and capable of producing different shapes and sizes to fit every requirement. Moreover, it has great flexibility to switch between shapes and sizes, making it an ideal choice for manufacturers who want to produce different products using the same machine.

4. Time-Saving

Time is a valuable asset for any business, and our Chinese Roll Forming Machines are designed to save time. Our machines have high-speed production capabilities while also ensuring the high accuracy of the product.

5. User-Friendly

We understand that time is money, and so not everyone has the luxury of time to take jobs for fixing or repairing the machine. Our Chinese Roll Forming Machines are user-friendly and easy to operate, making it easier for suppliers to train their staff on machine usage.

Machine Specifications

Our Chinese Roll Forming Machines are designed to meet specific client requirements, and so, we have a range of specifications to choose from. Below are the general specifications for our machines:

1. Material Thickness – 1.0mm to 3.0mm

2. Material Width – 1000mm to 1500mm

3. Speed – 0-15m/min

4. Roller Material – 45#steel, quenched HRC 58-62, surface coated with chrome

5. Shaft Material – 45#steel, with tempering and high-frequency quenching

Applications of Our Chinese Roll Forming Machines

Our machines are used in various applications across different industries, and below are some areas we have worked with:

1. Construction Industry – for the production of metal roofing and siding panels, gutters, downspouts, fascia, and trims.

2. Automotive Industry – for production of vehicle body parts, structural frames, and edges.

3. Electrical Industry – for production of electrical enclosures, switch boxes, and control boxes

4. HVAC Industry – for production of ductwork, ventilation equipment, and air conditioning enclosures.

In conclusion, our Chinese Roll Forming Machines are high-quality equipment designed to meet clients' expectations from different industries. We pride ourselves on providing durable and user-friendly machines at a competitive price. Get in touch with us today to learn more and to start the process towards increasing your manufacturing output.

Introduction

Chinese Roll Forming Machine is a production equipment that can be used in highways, bridges, water conservancy construction, and other industries because it can produce a variety of high-strength corrugated metal materials. It can use rolls to roll raw materials into specific shapes. Moreover, due to the high degree of automation of the production process, the product quality is very stable and the specifications are very consistent. You can use the computer control system time to accurately control the size of the product, and you can also grasp the production progress and situation of the machine very well.

Features

The steel belt bracket can make the Chinese Roll Forming Machine more stable and stable when running, less prone to noise, and safer.

Galvanizing treatment can make it more corrosion-resistant and adapt to a variety of production environments.

The intelligent operating system can simplify the production process, and can also save labor and costs.

The specifications of the Chinese Roll Forming Machine and various accessories can be customized according to the needs of customers.

Technical Parameter of Product Line:

|

1. Processing Thickness: |

0.25-0.8mm or as per customer request |

|

2. Roller Driven: |

Chain |

|

3. Processing material: |

GI or as per customer request |

|

4. Line speed: |

20-25m/min |

|

5. Rolling rows: |

16 rows |

|

6. Rolling diameter: |

40mm |

|

7. Dimensions: |

8.5m*1.5m*1.6m |

|

8. Weight: |

5t |

|

9. Power: |

4kw+4kw |

|

10. Testing Material: |

Q195 or Q235 |

|

11. Voltage: |

380V 50HZ or as customer's request |

|

12. Control Style: |

PLC |

*Equipment Parts

1. Supporting frame

2. Feeding platform

3. Automatic shearing system

4. Hydraulic system

5. Unfolding system

6. Computer control system

7. Automatic counter

8. Receiving table

*Process Flow

Decoiling-loading-molding-cutting-off-discharging

1. Ground-level land

2. 5T overhead travailing crane

3. Space for storing the material&machine

4. Road for vehicle moving

5. Workman: 2, operator and porter

Why choose us?

- Our company is focused on exceeding our customers' expectations and delivering exceptional value.

- Our Chinese Roll Forming Machine is inexpensive, experienced, efficient and credible in earning the confidence and cooperation of customers around the world.

- We strive to provide the best possible customer service to our clients.

- We believe in the self-discipline, judgment and dedication of our members, and we promote positive two-way communication, mutual respect and tolerance.

- Our products are both easy to use and maintain, saving our customers time and money.

- We have perfected our product information reserve by building a strong information platform for domestic and international procurement.

- We are constantly exploring new and innovative ways to improve our products and services.

- The company has won the market with its own quality and excellent service, and at the same time has won the trust of customers.

- Our skilled technicians are always available to provide support and assistance when needed.

- Our company will carry out scientific management of our products in strict accordance with the standards, so as to maintain fair competition and promote sustainable development.

Hot Tags: chinese roll forming machine, Gutter Roll Forming Machine, CZ Purlin Roll Forming Machine, Metal Roofing Roll Former, Roll Forming Machine for Corrugated Sheet, Racking Shelf Roll Forming Machine, Deck Roll Forming Machine