Steel Frame Rollformer

Description

Introducing the Steel Frame Rollformer: Transforming the Construction Industry

As the world population continues to grow, the demand for new and improved housing and buildings also increases. With this demand, there is a need for efficient and effective construction solutions that guarantee quality and durability. One such solution is the Steel Frame Rollformer – a revolutionary product that is transforming the construction industry.

At our manufacturing company based in China, we specialize in producing high-quality Steel Frame Rollformer machines that are used to create perfect steel frames for construction projects. Our Steel Frame Rollformer offers a simplified and efficient approach to steel frame production, with unparalleled results. In this product introduction, we will take a closer look at the Steel Frame Rollformer and what makes it an excellent choice for merchants in countries outside of China.

Simplified Production

One of the most significant benefits of using our Steel Frame Rollformer is the simplified production process. The machine works by feeding steel coils of different sizes into the machine, which creates a pre-determined steel profile as it passes through various rollers. This process is automated, which means that it requires minimal human intervention, reducing the cost of labor and speeding up the production process.

Additionally, our Steel Frame Rollformer is easy to use and maintain, making it an ideal choice for companies looking to streamline their production processes. By using our Rollformer machines, merchants can increase their production output, reduce the time needed to create steel frames, and subsequently increase their profits.

Customizable Solutions

Another benefit of the Steel Frame Rollformer is its versatility. Our machines can produce different types of steel profiles that meet the specific needs of our clients. Whether it is for roofing, flooring, or wall applications, our Steel Frame Rollformer can make it happen.

We understand that different regions have different construction requirements, which is why we offer adaptable solutions to our clients. Additionally, our machines can be configured to produce profiles of different shapes and sizes, depending on the client's specifications. This makes our Steel Frame Rollformer an excellent choice for merchants looking to provide customized steel frames to their clients.

High-Quality Outputs

Quality is a top priority for us, and we ensure that all our Steel Frame Rollformer machines produce high-quality outputs. Our machines are equipped with advanced technology that ensures each steel profile produced is accurate and precise, with minimal wastage. Our machines can produce steel frames of different thicknesses, depending on the client's needs, while still maintaining their structural integrity.

Moreover, our machines are durable and require minimal maintenance, ensuring that they produce high-quality steel profiles for an extended period.

Cost-Effective

When considering any production process, cost is always a crucial factor. At our China-based company, we understand this, which is why we designed our Steel Frame Rollformer to be cost-effective. By automating the production process and reducing the cost of labor, we can offer our machines at highly competitive prices without compromising on quality.

Merchants can also save on transportation costs because our Steel Frame Rollformer machines can be easily shipped to various locations worldwide. Additionally, clients can enjoy the benefits of having steel frames produced in-house, which reduces time and expenses.

In conclusion, our Steel Frame Rollformer offers merchants an efficient, simplified, and cost-effective solution for steel frame production. We believe that our machines can transform the construction industry by providing high-quality, customizable, and durable steel profiles, reducing production costs, and improving output. Our machines are designed to meet different client specifications and can be shipped worldwide. We can guarantee that our Steel Frame Rollformer will enhance any merchant's production process, bringing them closer to meeting their production goals.

Introduction

Steel Frame Rollformer is used to produce various sheets and is widely used in various industrial factories, warehouses, supermarkets, shopping malls, and other places. This machine has fast production speed and high production efficiency, so it is deeply loved by customers. High degree of automation to improve production accuracy. Moreover, a high degree of automation can ensure the uniformity of the steel frames produced, and they will not become larger or smaller. We have been engaged in production and operation for many years, with rich experience and mature technology, so we can improve the best products and services for you.

Features

1. High automation to achieve low error, high precision, and high efficiency, while reducing labor costs.

2. The entire appearance is very sturdy, which can counteract the vibrations generated during production, thereby extending the product's service life.

3. The outer surface of this Steel Frame Rollformer is firm, with good corrosion resistance and waterproofing.

4. Capable of producing steel frames of different specifications, sizes, and thicknesses to meet the needs of different industries.

Description | Specification |

Roll Forming Machine | Double door frame |

Material width | 3 sizes. Waiting for buyer exactly profile |

| Option: by PLC (It can be adjust by PLC and also in hand wheel) |

Base frame | Base frame 20 mm thick steel plate process the surface on CNC planer to keep it leveling and drill bolts and key slot by CNC |

Rolling Speed | 12-15m/min (not include cutting time) |

Rolling Thickness | 1.2-2.0mm or as per request |

Material | GI or metal or as per customer request |

Control System | PLC (Panasonic) as list in the note |

Un Coiler | 3 ton manual decoiler |

Leveling | Up in 3 roller, down in 4 roller |

Roller Stations | About 20 stations |

Roller Material | Gcr15, coated with chrome HRC58-62 degree |

Shaft Material and DIA | ¢70mm, material is 45# forge steel |

Maim Motor Power | 11kw brake motor |

Hydraulic Station Power | 5.5kw |

Hydraulic Pressure | 20Mpa |

Capacity of tonnage for punching | 22Tons |

Hydraulic pump brand | Famous Brand in China |

Bearing brand | Harbin |

Other brand list | PLC: Panasonic |

Punching | 3 units pre-punching and one unit cutting & punching include including 6 set 45 degree angle moulds. |

Cutting | Hydraulic post-cutting for cut end product |

Extra cutter | One more cutter for each profile |

Material Of Cutting | Cr12Mov quenching 58-62ºC |

Electric Source | 380V, 60HZ, 3 phase |

Way Of Drive | 1.2 inch single chain |

Color Of The Machine | Yellow and blue |

Machine Type | Iron Cast |

Emergency switch | In main machine and control panel all have emergency switch for forbid any urgently accident. |

Protect cover | Complete mobile safty cover from roll forming to the cutter |

Size of the machine | L*W*H 12m*1.2m*1.2m |

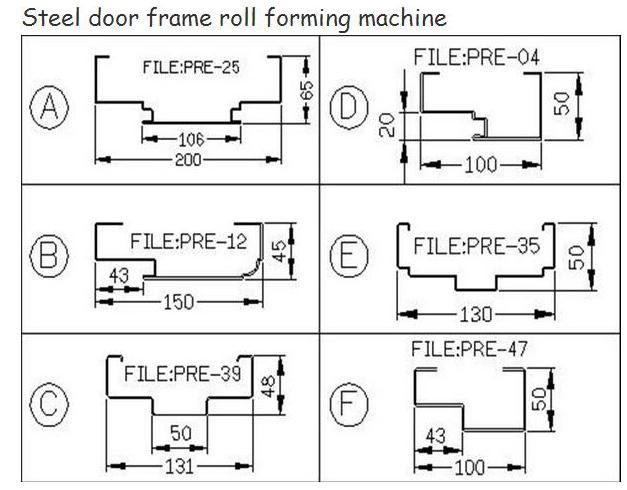

Profile Drawing

As per customer request

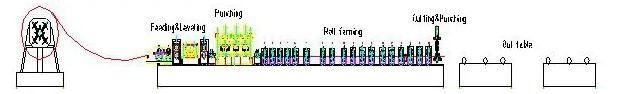

Process Drawing

Why choose us?

- We're proud of our reputation for providing high-quality Metal Roll Former products to our customers.

- Our company has always believed that to retain customers, the first step is to make a good product. Without a great product, no amount of publicity is of any use.

- Our Metal Roll Former products are backed by our commitment to providing exceptional service and support to our customers.

- We insist on standing in the customer's angle to think about the problem, seek truth from facts for customer service.

- Our Metal Roll Former products are made from the finest materials and with expert craftsmanship.

- We are the best manufacturer of Steel Frame Rollformer in China.

- Our Metal Roll Former products are known for their exceptional quality and durability, making them an excellent investment.

- The company fully implements the unified purchase and sales strategy, maximizes the company's material procurement and product sales advantages, and enhances the company's profitability.

- We are a Chinese factory that specializes in high-quality Metal Roll Former products and professional services.

- Our company has strong strength, integrity and the policy of small profit and quick turnover, which has created a good reputation for the company.

Hot Tags: steel frame rollformer, Rolling Shutter Roll Forming Machine, Metal Rollfomer, Roof Sheet Roll Forming Machine, Roller Shutter Forming Machine, Steel Decking Sheet Roll Forming Machine, Purlin Roll Forming Machine