Metal Rollfomer

Description

Introducing the Metal Rollformer – Your Solution to High-Quality, Affordable Metal Forming

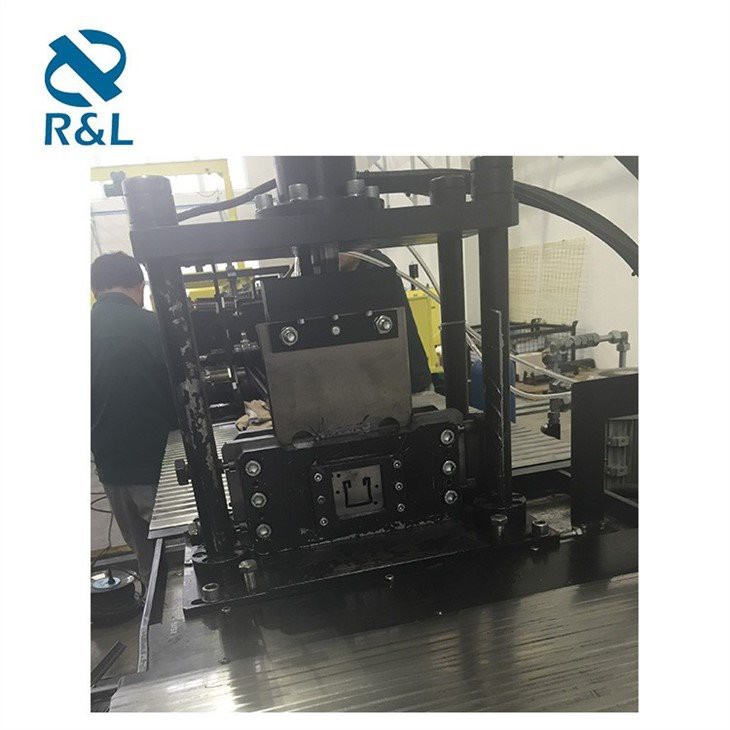

Are you looking for reliable and cost-effective solutions to your metal forming needs? Look no further than our Metal Rollformer – a state-of-the-art machine that is designed to help you achieve precise, high-quality metal forming results, no matter the complexity of your project.

At our manufacturing facility in China, we are committed to designing and producing innovative machines that meet the evolving needs of our clients, whether they operate in the construction, roofing, or other metalworking sectors. We have invested in advanced technology, state-of-the-art equipment, and a skilled workforce to ensure that our machines are of the highest quality, and that they can withstand the toughest working environments.

So, what makes our Metal Rollformer stand out from the crowd? Here are some key features and benefits that we would like to highlight:

1. High precision and versatility

Our Metal Rollformer is designed to deliver the highest precision, accuracy, and consistency in metal forming, thanks to its advanced control system, high-strength steel construction, and robust hydraulic and electrical components. This means that you can rely on our machine to produce custom-made profiles, complex shapes, and long-length panels with minimal waste or errors. Moreover, our Metal Rollformer is versatile enough to handle a wide range of metal materials, such as steel, aluminum, copper, brass, and zinc, as well as various gauges, thicknesses, and widths.

2. Low cost and high efficiency

We understand that cost-effectiveness is a top priority for many of our clients, which is why we have designed our Metal Rollformer to streamline your metal forming process and reduce your overhead costs. Our machine can operate at high speeds (up to 30 meters per minute), allowing you to produce more panels in less time and with fewer labor costs. Additionally, our Metal Rollformer requires minimal maintenance and energy consumption, so you can save more money and resources over the lifespan of the machine.

3. Easy to use and customize

We also know that ease of use and customization are crucial factors for our clients, especially those who are looking for a user-friendly and flexible metal forming solution. That's why our Metal Rollformer comes with intuitive software and user interfaces that allow you to control and adjust the machine settings with ease. You can also customize the profiles, sizes, colors, and coatings of your metal panels to meet your specific design and functionality requirements. Our experienced engineers and technicians are always available to provide you with technical support, training, and solutions for your unique challenges.

4. Safe and durable

Last but not least, we prioritize the safety and durability of our Metal Rollformer, as we understand that working with metal materials can pose certain risks and challenges. That's why our machine is equipped with multiple safety features, such as emergency stop buttons, safety guards, and sensors, to prevent accidents and injuries. We also conduct rigorous quality control and testing procedures to ensure that our Metal Rollformer meets or exceeds international safety and performance standards, such as CE, ISO, and UL. Additionally, we offer extended warranties and after-sales service to ensure that your investment is protected and well-maintained.

In conclusion, if you are looking for a high-quality, affordable, and reliable metal forming machine that can help you enhance your productivity, profitability, and competitiveness, there's no better choice than our Metal Rollformer. Please do not hesitate to contact us for more information, technical specifications, or a customized quote. We are always ready to partner with you and support your business growth.

Description

Metal Rollfomer refers to equipment that can calender raw materials with a rotating roll with a smooth surface or a certain shape to produce a certain shape product. It is very suitable for the production of required materials for civil construction, steel structure workshops, road construction, and other industries. Our products are mainly made of various steel materials, including forged steel and polished and heat-treated steel. The overall strength is very high, so it can also play a better role in processing, and at the same time, it is more durable and has good working environment adaptability.

In addition, our equipment is very stable and safer in operation due to the selection of various materials and the stable, compact machine structure. The stable body can further reduce the noise caused by vibration. At the same time, equipped with automatic production devices such as encoders, the operation of Metal Rollfomer is simpler and the production efficiency is higher.

Details

|

Parameters |

Metal Rollfomer |

|

Driving Motor |

7.5KW |

|

Cutter Motor |

3KW |

|

Forming Station |

16Step/16Step |

|

Working Speed |

16-20m/min |

|

Thickness for Steel |

1.5-2.0mm/1.0-1.2mm or as per request |

|

Changeover mode |

Manual change |

|

Shaft Diameter |

75mm |

|

Shaft Material |

High grade 45# forged steel |

|

Roller Material |

45# steel with polished and heat treatment |

|

PLC Cabinet |

Schneider, Delta, Siemens |

|

Encoder |

Omron |

|

Sprocket Wheel |

45 steel high-frequencies quench |

|

Cutting |

Post-cutting |

|

Blade material |

Cr12 steel |

|

Main Machine Frame |

Archway |

|

Roofing Material |

PPGI, GI steel G330-550 |

|

Machine Color |

Blue + black Or Customization |

|

Voltage |

380V/50HZ/3PH or According to requirements |

|

Total Production Line Size |

6500*1300*1100mm |

|

Total Production Weight |

10500KGS |

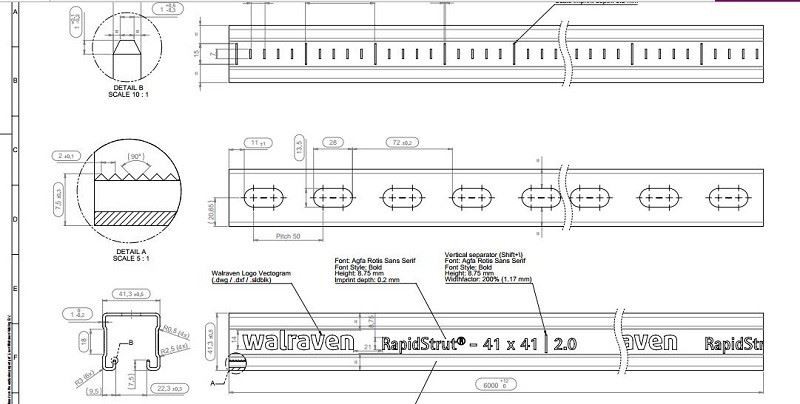

Profile Drawing

Company Profile

Wuxi J&R Roll Former Co., Ltd is a manufacturer of roll forming machines, CZ purlin roll former, silo bin forming machines, and other similar metal cold roll forming machines. We have a strong team for design and installation.

Our machines are mainly used in steel and agricultural structure industries for producing steel C and Z purlins, load-bearing plates for buildings, wall and roof protective structure colorful steel plates, colorful decorating and protecting steel plates for high-grade steel structure residences; Environment industry anode plate and cathode plate lines for removing the dust; traffic-transport industry freeway guardrail plates, vehicles roll-forming materials serials such as goods shelf boards and cabinet screen plates. We can also supply all kinds of decoilers (also called uncoilers), levelers, slitting decoilers, and cut-to-length shear stackers.

We have advanced production equipment and our engineers and technicians have rich experience in designing, developing, and manufacturing machinery. They pay close attention to and keep up with the developing trend of steel forming technology and use new technology in manufacturing roll forming machinery. Our machines work with high efficiency, high flexibility, and low cost.

Why choose us?

- Our Metal Roll Former products are some of the best on the market, and we stand by their quality.

- Adhering to the principle of customer first, true and trustworthy, mutual benefit and win-win, with good cost performance, professional processing service and all-round after-sales service, we have established a good cooperative relationship with many manufacturers.

- Our Metal Roll Former products are of exceptional quality, and we take pride in our expert craftsmanship.

- Our company has accumulated some long-term cooperative partners for ourselves with our good faith, considerate and warm service.

- We're dedicated to providing the best possible Metal Roll Former products and service to our customers.

- Our sincere sense of social responsibility have gained widespread attention and praise from all walks of life.

- We are a Chinese factory that specializes in high-quality Metal Roll Former products and professional services.

- After years of development, our company has organized a professional production team about Metal Rollfomer and has an independent production workshop. Now we have a number of advanced production lines and integrate production, design, sales, and considerate after-sales, becoming a professional comprehensive enterprise.

- Our Metal Roll Former products are made to withstand even the most demanding applications and environments.

- In the current increasingly fierce market competition, our company will continue to strive for perfection, continue to deepen the strength of corporate scientific management, improve the quality of Metal Rollfomer, and provide customers with perfect and enthusiastic after-sales service.

Hot Tags: metal rollfomer, Double Layer Roll Forming Machine, Sheet Making Machine, Roofing Sheet Making Machine, Cold Roll Former, Guardrail Roll Forming Machine, Corrugated Forming Machine