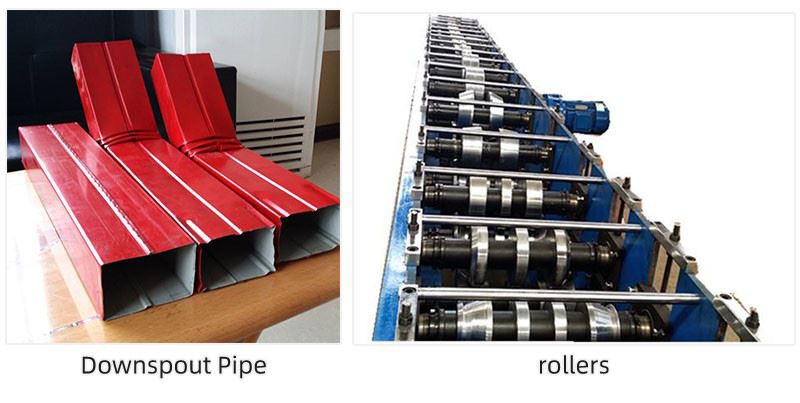

Downspout Pipe Roll Forming Machine

Description

Introduction:

Welcome to our Downspout Pipe Roll Forming Machine, a revolutionary product that brings speed, flexibility, and cost-effectiveness to the process of manufacturing downspout pipes. Our machine is designed to help merchants produce high-quality downspout pipes in bulk and meet the growing demand for these essential building components. In this product introduction, we will explore the features, benefits, and specifications of our machine and explain why it is a must-have for merchants looking to expand their business.

Features:

Our Downspout Pipe Roll Forming Machine is packed with features that make it stand out from the competition. Here are some of the features that make our machine the clear choice for manufacturers:

1. High-Speed Production:

Our machine can produce up to 30m of downspout pipe per minute, making it one of the fastest machines on the market. This high-speed production allows merchants to complete large orders quickly and efficiently, reducing lead times and increasing profitability.

2. Flexible Design:

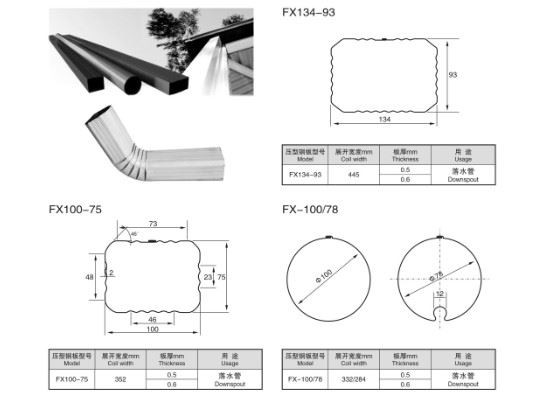

Our machine is built with a flexible design that allows merchants to create downspout pipes of different shapes and sizes, depending on their clients' needs. The machine can produce pipes with diameters ranging from 50mm-120mm, and lengths of up to 9meters.

3. Ease of Use:

Our machine is designed to be easy to use, even for those with limited technical expertise. It comes with a simple interface that allows merchants to set the machine's parameters, adjust the speed, and monitor the production process.

4. High-Quality Output:

Our Downspout Pipe Roll Forming Machine is designed to produce pipes with a high level of accuracy and consistency, ensuring that the final product meets the required standards. The machine uses high-quality materials and components, which ensures durability and longevity.

Benefits:

The benefits of our Downspout Pipe Roll Forming Machine are extensive, and we believe that merchants who invest in this machine will see significant returns on their investment. Here are some of the benefits of our machine:

1. Increased Production:

Merchants who invest in our machine can significantly increase their production capacity, allowing them to meet the growing demand for downspout pipes. This increased production can lead to increased revenue and profitability, helping merchants to grow their business.

2. Reduced Costs:

Our machine is designed to be cost-effective, reducing the cost of producing downspout pipes significantly. Merchants can save on labor costs, material costs, and other production-related expenses, leading to increased profitability.

3. Improved Quality:

The accuracy and consistency of our machine's output mean that merchants can produce high-quality downspout pipes that meet or exceed their clients' expectations. This improved quality can lead to increased client satisfaction and repeat business, providing long-term benefits for merchants.

4. Competitive Edge:

Merchants who invest in our Downspout Pipe Roll Forming Machine gain a competitive edge over their rivals, as they can produce downspout pipes more quickly and cost-effectively. This edge can lead to increased market share and business growth, providing long-term viability for merchants.

Specifications:

Our Downspout Pipe Roll Forming Machine comes with the following specifications:

1. Material Thickness: 0.3mm-0.8mm galvanized steel

2. Main Motor Power: 5.5kw

3. Hydraulic Power: 5.5kw

4. Cutting Device: Hydraulic Cutting

5. Forming Stations: 22

6. Machine Weight: 6.5 tons

7. Machine Size: 10000mm × 1500mm × 1500mm

Conclusion:

Our Downspout Pipe Roll Forming Machine is an excellent investment for merchants looking to expand their business and improve their production processes. With its high-speed production, flexible design, ease of use, and high-quality output, this machine offers a range of benefits that can help merchants grow their business while reducing costs and increasing profitability. We invite you to contact us for more information about our machine and see how it can benefit your business.

Introduction

A downspout is a pipe that collects rainwater and directs it underground. Our Downspout Pipe Roll Forming Machine is a fully automatic processing equipment that can produce metal downspouts made of iron, copper, and aluminum at high speed, and the shapes are very diverse (round, square, semicircular, and other pipes can be realized by this equipment ). The equipment is fully automatically controlled by a computer and equipped with raw material uncoiler. When the raw material enters the feed port, the machine can drive the plate and complete the rolling. After multiple processes, the computer will automatically cut off the control, and the high-precision product will be produced.

Features

1. Downspout Pipe Roll Forming Machine is mainly composed of an unwinding machine, frame, forming part, cutting part, electric control cabinet, and other parts.

2. The PLC control system can not only make the molding process more precise but also provide various protections for the production process.

3. The tempered steel parts are the main material of the bed, so the machine has good stability and is not easy to deform after high-intensity use.

4. The gearbox transmission structure provides great convenience for the forming process, shortens the processing time, and prolongs the service life of the equipment.

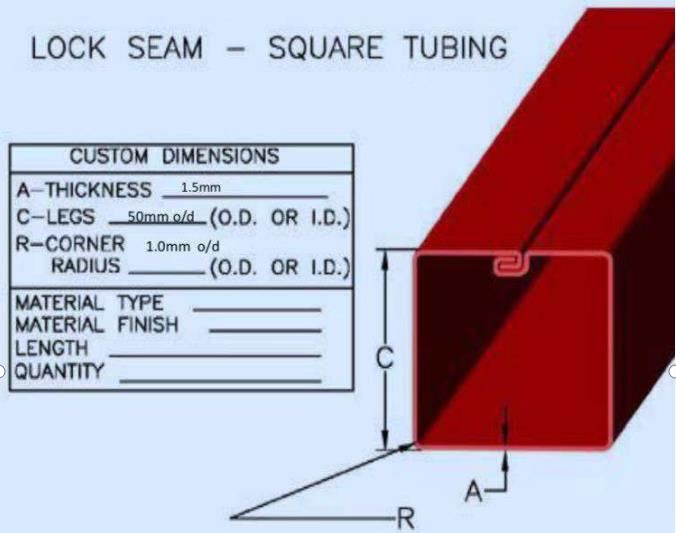

1. Profile Drawing

2. Equipment List

a. Decoiler…………………………1 pcs

b. Roll Forming Machine………………………1pcs

c. Collection Table: 1 pcs

3. Main Technical information

a. Decoiler: Passive, double support, Max loading weight: 3T

b .Unfold Width: up to the tube size

c. Thickness: 1.5mm

d. Forming Speed: 6-8m/min

e. Forming Station: 18

f. Frame: 36# I steel welded

4. Main Shaft

4.1 Material: GCr15

4.2 OD: 70mm

5. Roller

5.1 Material: GCr15

5.2 The single surface of Cr electroplating rollers: 0.05mm

6. Wall Thickness: 18mm

7. Transmission: chain

7.1 Name: bush roller chain

7.2 Model: 20A-1

7.3 Chain Material: high quality 45# steel

6.4 Heat Treatment: HRC45-50°

8. Motor: famous brand in China

8.1 Power: 7.5KW —— 1pcs

8.2 Original: China

8.3 Hydraulic Cutting, power: 2.2KW

9. PLC: Panasonnic

10. Machine Pictures we have manufactured

Why choose us?

- Our machines are designed to reduce labor costs and increase efficiency.

- We firmly believe that if we have an unbreakable team spirit, we will produce the best results.

- Our machines are easy to use and require minimal maintenance, saving our customers time and money.

- Employees bring more vigor and vitality to the company, and their active and enthusiastic participation will enable the company to continue to progress and develop and grow.

- Our products are made with precision and are of the highest quality.

- With the increasingly fierce market competition, in addition to price competition, brand competition, service competition, quality competition and other means of competition, many manufacturers increase channel competition and take various strategies to compete for marketing channel resources.

- We are a Chinese factory offering professional and high-quality metal roll forming machines.

- Our goal is to be the main force of the industry leader and to be a respected supplier of the Downspout Pipe Roll Forming Machine.

- Our metal roll forming machines are designed to be highly efficient and reduce production costs.

- The company takes "only the best" as its corporate spirit and focuses on Downspout Pipe Roll Forming Machine production. Through continuous improvement of the industrial supply chain and integration of advantageous resources, we will provide customers with the best experience and the most perfect products.

Hot Tags: downspout pipe roll forming machine, Gutter Forming Machine, Corrugated Sheet Making Machine, Roll Forming Machine for Corrugated Sheet, Double Layer Roof Tile Roll Forming Machine, C Section Rollformer, Roll Former Machine