C Section Rollformer

Description

Introduction

Welcome to our C Section Rollformer product page! We are excited to introduce you to our top-notch manufacturing technology. We are a Chinese manufacturer known for providing high-quality products to merchants all over the world. We take great pride in our products and our customer service, and we are pleased to offer our newest product, the C Section Rollformer.

We believe that our C Section Rollformer is one of the best and most reliable metal forming machines in the market today, and we’re excited to share its features and benefits with you.

What is a C Section Rollformer?

A C Section Rollformer is a metal forming machine that uses rolls to shape a strip of metal into a C-shaped section. It is used in a wide range of industries that require metal structures, such as construction, automotive, aerospace, and engineering. It can be used to create a variety of C-shaped sections, each with different dimensions and thicknesses. The C Section Rollformer is an efficient and reliable tool for producing high-quality metal products.

Features and Benefits

Here are some of the features and benefits of our C Section Rollformer:

1. High Precision

Our C Section Rollformer is designed with high precision and accuracy, ensuring that the final product is of the highest quality. It uses advanced technology to control the thickness, width, and length of the C-shaped sections, which allows for consistent and precise results.

2. Easy to Use

Our C Section Rollformer is easy to use, even for beginners. It is designed with user-friendly controls that are easy to understand, and it comes with a detailed instruction manual that provides step-by-step guidance on how to use it.

3. Durable and Long-Lasting

Our C Section Rollformer is made of high-quality materials that are strong and durable. It is designed to withstand the rigors of daily use, and it can last for many years with proper maintenance.

4. Versatility

Our C Section Rollformer can create a wide range of C-shaped sections, each with different dimensions and thicknesses. This means that it is versatile, and can be used for a variety of applications.

5. Cost-Effective

Our C Section Rollformer is cost-effective, which means that it can save you money in the long run. It is designed to be efficient and fast, which means that it can produce high-quality metal products in less time than other machines. This can reduce your labor costs and increase your profit margins.

Applications

Our C Section Rollformer can be used in various industries and applications, including:

1. Construction

Our C Section Rollformer is perfect for creating metal structures used in construction, such as beams, columns, and trusses.

2. Automotive

The C Section Rollformer is also used in the automotive industry to create parts for cars and trucks, such as chassis components, frames, and suspension systems.

3. Aerospace

In the aerospace industry, the C Section Rollformer is used to create complex metal parts and structures, such as engine components and structural elements.

4. Engineering

The C Section Rollformer is also used in engineering to create metal parts and structures for various projects, such as bridges, buildings, and infrastructure.

Conclusion

In conclusion, our C Section Rollformer is a high-quality metal forming machine that provides users with precision, efficiency, and versatility. Its durability and cost-effectiveness make it a valuable investment for any business that requires metal structures. If you’re interested in learning more about our C Section Rollformer, contact us today! We look forward to hearing from you.

Description

The C Section Rollformer is a single roll-forming unit that can produce various finished C-section materials with a set of rolls. The machine is mainly composed of a loading frame, leveling equipment, punching equipment, cutting equipment, a hydraulic system, a computer control system, and other parts. It has excellent stretching, bending, compression, and other characteristics. With computer assistance, it can automatically cut to length, punch holes, etc. with high accuracy and convenience. C Section Rollformer is often used in factories, warehouses, exhibition halls, theaters, gymnasiums, etc. because of the ability to manufacture various lightweight structures made of steel plates and other materials, and these materials are often difficult to manufacture by ordinary hot rolling methods. Production of load-bearing materials. The produced products have uniform wall thicknesses and various cross-sections. In addition, its main production process includes feeding, leveling, flat punching, roll forming, hydraulic cutting, receiving, and so on.

1. Process

Decoiler — Feedin g— Leveling — Flat punching — Roll Forming — Hydraulic Cutting — Collection

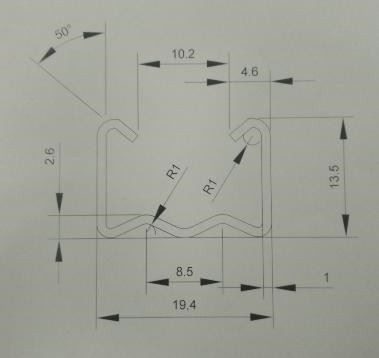

2. Profile Drawing

Equipments

Decoiler

Single-head decoiler, load the coil from one side

Negative decoiler

Max loading weight: 5000Kg

Max coil O.D: 1600mm

Max width: 500mm

Feeding & Leveling

Decoiler and then go to the guiding Roller ( can be adjusted from left to right)

Go to the feeding rollers, the O.D is ¢100mm, the rollers is made up from 45# steel, quenching 48°-52°

Leveling: upper 3 roller and down 4 roller, quenching heat treatment

Punching

Hydraulic punching

Pump diameter: ¢120mm

Working pressure: 20mpa

Punching die material: Cr12, quenching to 58°-62°

Hydraulic Power: 7.5KW

Size: 1.5m(Length) *0.9m(Width)*1.2m (Height)

Roll Forming

Main power: 11KW

Original: Changzhou, China

Shaft O.D: ¢70mm, 45# steel

Roller Material: GCR15quenching to 58°-62°

Station: 23

Speed: 0m-15m/min (without punching)

Inverter: Simphoenix (Voltage 380V, 50HZ)

Panasonnic PLC control panel

Cutting

Blade material: Cr12, quenched to 58°-62°

Oil Pump O.D: 100mm

Working pressure: 20mpa

Working stroke: 60mm

Machine Size

Length: 13.5m; Width: 1m; Height: 1.6m

7. Collection Table

Welded from 60mm*40mm square tube

Specification: Length 1.5m*Width 0.8m*Height 0.6m-1m

Constitute

Negative decoiler: 1 pcs

C Section Rollformer (feeding. Leveling, forming, punching, PLC, Hydraulic station, cutting): 1 pcs

Collection table: 2 pcs

Manual: 1 pcs

Why choose us?

- We take pride in our ability to deliver Metal Roll Former products that meet or exceed customer expectations.

- Adhere to innovative development as the development base point of various undertakings, and coordinate development as the fundamental path of sustainable development!

- Our Metal Roll Former products are made with a focus on quality and craftsmanship, ensuring their superior performance and longevity.

- As a professional C Section Rollformer factory, we have the responsibility to let you enjoy high-quality products, professional services and perfect after-sales.

- Our Metal Roll Former products are some of the best on the market and are backed by our commitment to customer satisfaction.

- In the enterprise internal management, our company regards integrity as a responsibility and attitude.

- Our Metal Roll Former products are designed with precision and care, ensuring their superior quality.

- We take the initiative to study, consciously exercise, and enhance the business quality to complete the business tasks outstandingly.

- We're a reliable and experienced supplier of Metal Roll Former products, and we're committed to meeting the needs of our customers.

- We strive to reduce the cost of our C Section Rollformer in the hope of bringing maximum benefits and profit margins to our customers and consumers.

Hot Tags: c section rollformer, Roof Roll Former, C Purlin Rollformer, Cold Roll Forming Machinery, Floor Deck Roll Forming Machine, Corrugated Sheet Making Machine, Roofing Sheet Making Machine