Metal Roofing Roll Former

Description

Metal Roofing Roll Former: The Perfect Solution for High-Quality Metal Roofing

Are you tired of substandard roofing solutions that cannot withstand harsh weather conditions? Look no further than our Metal Roofing Roll Former – the ideal solution for all your metal roofing needs.

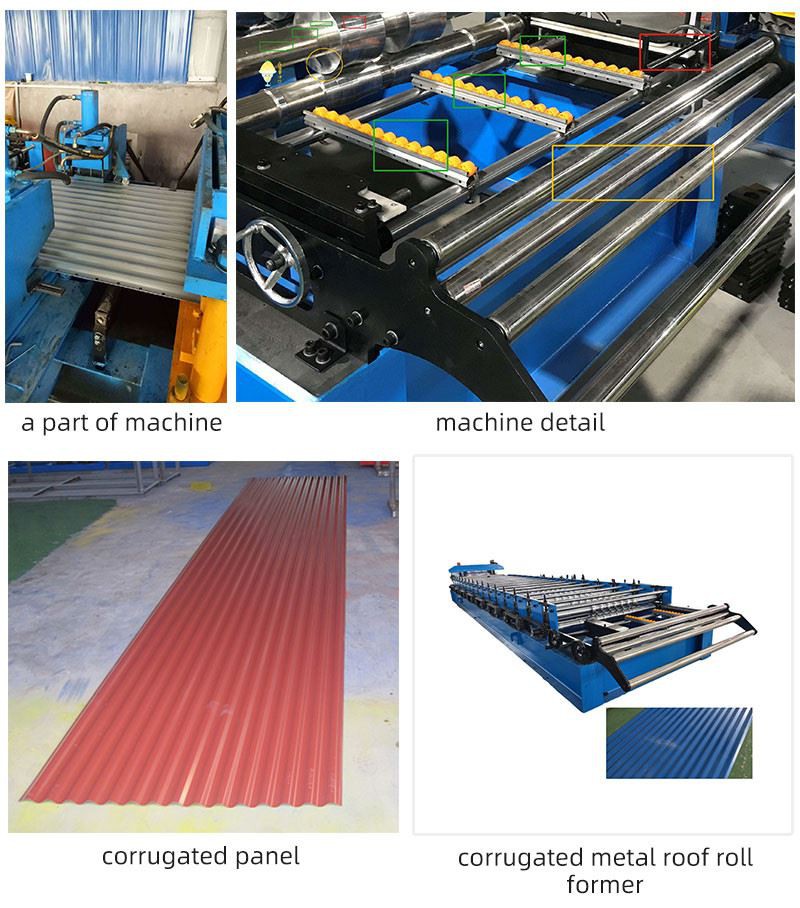

Our Roll Former is a state-of-the-art machine that can help fabricate high-quality metal roofing sheets and panels with ease. The machine works by passing a metal coil through a series of rollers until it forms the desired panel or sheet shape. It is perfect for those who want to manufacture top-of-the-line metal roofing solutions for their customers.

Our Metal Roofing Roll Former features:

1. Durability: Our Roll Former is made of high-quality materials that last long and offer excellent performance. It has a sturdy structure that can handle heavy-duty work and withstand the toughest conditions.

2. Efficiency: Our machine is designed to work efficiently, reducing the time it takes to manufacture high-quality metal roofing solutions. It can produce a variety of panel shapes and sizes, meeting the demands of your customers.

3. Versatility: With our Roll Former, you can produce a wide range of roofing solutions, including corrugated roofing, standing seam panels, and more. This means that you can cater to various customers' needs and requirements.

4. Ease of use: Our Roll Former is easy to use and requires minimal maintenance. It comes with a user-friendly interface that allows you to operate the machine with ease, reducing the need for extensive training.

5. Cost-effectiveness: Our Metal Roofing Roll Former is an excellent investment for your business as it offers a high return on investment. With its efficiency and versatility, you can produce more roofing solutions in less time, resulting in higher profits for your business.

Why choose our Metal Roofing Roll Former?

At our company, we are committed to providing our customers with high-quality machines that meet their business needs. Our Metal Roofing Roll Former is no exception. Here are some of the reasons why our Roll Former is the perfect solution for you:

1. Quality: Our Roll Former is built to last and provides top-notch quality metal roofing solutions. It has been tested under extreme conditions, and we guarantee that it will meet or exceed your expectations.

2. Customization: We offer customized solutions to meet your particular business needs. Whether you require a specific size or shape of panel or sheet, we can provide you with the right solution.

3. Support: We offer comprehensive support throughout the manufacturing process, ensuring that you get the best out of our Metal Roofing Roll Former. From installation to training and maintenance, we are here to help.

4. Price: Our Roll Former is competitively priced, making it an affordable solution for small and large businesses alike. Moreover, with its cost-effectiveness, you can quickly recoup your investment and start making profits in no time.

Conclusion:

In a nutshell, our Metal Roofing Roll Former is a must-have for any business involved in metal roofing solutions. It offers quality, versatility, and efficiency, making it the perfect solution for any business seeking to produce high-quality roofing solutions. If you are interested in purchasing our Roll Former, please do not hesitate to contact us today. We look forward to working with you and helping your business succeed.

Introduction

Metal roofs are commonly used in sports venues, factories, warehouses, garages, exhibition centers, and other places, and this Metal Roofing Roll Former is precisely used to produce these metal roofs. The metal roof produced through this product has the advantages of high precision, high uniformity, and high-quality. The outer surface of this product is firm, with good corrosion resistance and waterproofing. The high degree of automation can effectively improve production efficiency while reducing production errors. If you have any questions about this product, you can always consult us.

Features

1. The outer frame has good seismic resistance, waterproofing, corrosion resistance, and oxidation resistance.

2. High degree of automation reduces the likelihood of manual intervention and operational errors.

3. We can produce various specifications of metal roofs, and each metal roof can have the same size.

4. High work efficiency, high work accuracy, and minimal work errors are all characteristics of this Metal Roofing Roll Former.

Applications of Metal Glazed Tile Roll Forming Machine:

The finished products are used as the roof and walls of gymnasiums, airports, theatres, factories, warehouses, garages, exhibition centers etc.

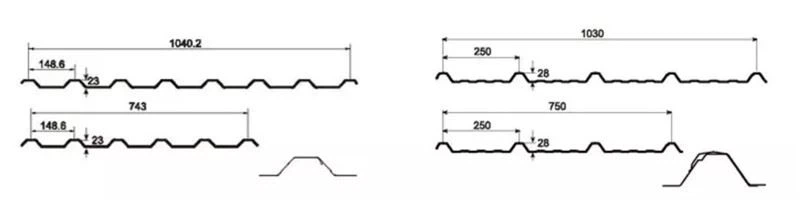

Profile Drawing

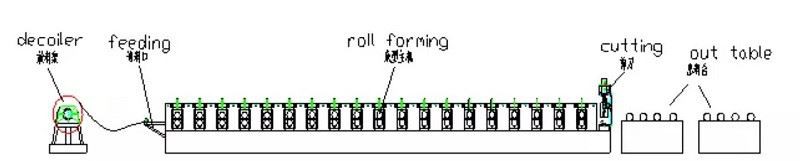

Process Drawing

The Features of Wheels:

All the wheels of the machine are made of 45# steel, hard chrome plated after finishing, with the advantages of corrosion resistance and long service time.

The Features of Shaft:

The shaft of the machine all adopts solid shaft, made of 45# bearing steel fine processing, has the advantages of high strength, long service life and so on.

PLC Control System:

PLC brand: Delta or customized Language:English Spanish Russian Chinese Control panel: Button or touch screen. HMI: easy to operate.

Hydraulic System:

Power: 3KW Hydraulic oil: 46# hydraulic oil Working pressure: 12-16Mpa adjustable Hydraulic oil into the hydraulic oil tank, the pump drive the cutter machine to begin the cutting job.

|

Raw material |

PPGI PPGL GI GL |

|

Shaft material |

High Grade No.45 Forged |

|

Cutting blade material |

Cr 12 High Grade Steel |

|

Roller material |

45#steel Chrome Plated |

|

Cutting type |

Automatic Hydraulic Cutting |

|

Roller Station |

Up layer:9 down layer:11 |

|

Diameter of shaft |

70mm |

|

Production Capacity |

8-12m/min |

|

Rolling thinckness |

0.3-0.8mm |

Why choose us?

- We take pride in our ability to provide high-quality Metal Roll Former products to our customers.

- We provide users Metal Roofing Roll Former with quality and ingenuity.

- Our Metal Roll Former products are made from the finest materials and with expert craftsmanship.

- We believe that the change of ideology is the beginning of cultural innovation, and it is the premise and foundation for cultivating new values.

- We are a Chinese factory that specializes in high-quality Metal Roll Former products and professional services.

- Build a diverse team, cultivate an inclusive atmosphere, a strong sense of collective honor and revolutionary heroism, as well as the friendship of life and death, and achieve one victory after another with a keen sense of smell, a fighting spirit and a strong sense of enterprising.

- We're a trusted partner for businesses looking for high-quality Metal Roll Former products and outstanding service.

- Our company has laid out supply chain assets such as processing, logistics, warehousing, and terminals. Through government-enterprise cooperation, we have built a large-scale intelligence platform for people's supply chain, and joined hands with the government to help the future development of blockchain.

- Our Metal Roll Former products are some of the best on the market and are backed by our commitment to customer satisfaction.

- Through years of development, we believe that our company will become a technological enterprise with its own characteristics.

Hot Tags: metal roofing roll former, Forming Machine, Deck Roll Forming Machine, Corrugated Steel Sheet Rollformer, Metal Roll Forming Machine, Chinese Roll Forming Machine, Gutter Forming Machine