Cold Roll Forming Machinery

Description

Cold Roll Forming Machinery is a highly advanced technology that allows for the rapid production of high-quality metal products. As a manufacturer located in China, we are proud to offer this advanced machinery to merchants in countries outside of China.

First, let's begin with what Cold Roll Forming Machinery actually is. This technology involves forming metal sheets and strips through a series of rollers to create a desired shape. This innovative technology produces a wide range of products including roof panels, wall panels, garage doors, and more.

At our manufacturing facility in China, we use the highest quality materials and state-of-the-art machinery to produce Cold Roll Forming Machinery that is second to none. Our team of expert engineers works tirelessly to design and produce machinery that is both reliable and efficient.

One of the main advantages of Cold Roll Forming Machinery is its ability to produce products in large quantities at a high rate of speed. This makes our machinery the perfect choice for merchants who need to produce large volumes of high-quality metal products quickly and efficiently. Additionally, our machinery requires very little maintenance, reducing the need for costly repairs over time.

Quality is a top priority for us, which is why we use only the finest materials in the production of our Cold Roll Forming Machinery. We use high-quality steel and other materials that are designed to last, ensuring that our machinery operates at peak performance for years to come.

Our Cold Roll Forming Machinery is also highly customizable, allowing merchants to produce products in a wide variety of shapes and sizes. This allows merchants to meet the unique needs of their customers, making our machinery an invaluable asset for any business.

Perhaps most importantly, our Cold Roll Forming Machinery is incredibly easy to use. Merchants can quickly learn how to operate our machinery and produce high-quality metal products in no time. This saves time and money, allowing merchants to focus on growing their business.

In conclusion, our Cold Roll Forming Machinery is an innovative technology that is ideal for merchants in countries outside of China. With its ability to produce high-quality metal products quickly and efficiently, our machinery is a must-have for any business looking to grow and thrive in today's competitive market. Additionally, our commitment to quality materials and expert engineering ensures that our machinery is built to last, providing years of reliable use. Contact us today to learn more about our Cold Roll Forming Machinery and how it can help take your business to the next level.

Introduction

Cold Roll Forming Machinery is a very commonly used steel forming machine, and its main product is a high-strength steel bar, a high-efficiency construction steel. The complete solution of this product includes an uncoiler, hydraulic shearing device, main roll forming system, PLC control system, and other components. The first production process is the unwinding of metal coils. After the guide rail enters the forming machine and is leveled, it will be rolled into a material with a specific cross-section according to customer requirements. It is then precisely cut by a hydraulic cutting unit. The automatically stacked products can be used by various industries after packaging.

Features

1. Cold Roll Forming Machinery's forming rolls are made of hardened steel, and a hard chrome coating makes them more wear-resistant and prolongs their life.

2. The advanced PLC control system and simple operation panel greatly reduce the operation difficulty of the equipment and can control the cutting accuracy within 1mm.

3. The finished material is flat and stable, and problems such as uneven thickness and cracking have been effectively controlled.

4. The stable base reduces the vibration during processing, so the noise is lower, which helps to improve the production environment.

Main Components of Garage Door Guide Rail Forming Machine

|

No. |

Item |

Quantity |

|

1 |

Decoiler |

1 Set |

|

2 |

Guide and Punch Rollers |

1 Set |

|

3 |

Main Roll Forming System |

1 Set |

|

4 |

Hydraulic Cutting device |

1 Set |

|

5 |

Hydraulic Station |

1 Set |

|

6 |

Run-out Table |

2 Sets |

|

7 |

Control System |

1 Set |

Technical Parameters of Garage Door Guide Rail Forming Machine

|

Suitable Material |

Coil Type |

GI, GL Coil |

|

Coil Thickness |

0.7~1.8mm |

|

|

Coil Width |

According to design |

|

|

Yield Strength |

250~350Mpa |

|

|

Decoiler |

Decoiler type |

Hydraulic |

|

Weight Capacity |

8 Tons |

|

|

Main Roll Forming |

Forming Station |

13~20 stations |

|

Roller Material |

45# Steel. Quenched. 0.05mm hard chrome coated |

|

|

Shaft Material |

45# Steel. Quenched. 0.05mm hard chrome coated |

|

|

Shaft Diameter |

50mm |

|

|

Drive Type |

Chain drive |

|

|

Forming Speed |

5~12m/min |

|

|

Main Power |

5.5 Kw |

|

|

Cutting device |

Cutting Device |

Hydraulic Cutting |

|

Cutting die Material |

Cr12MoV |

|

|

Cutting Tolerance |

+/-1mm (10m) |

|

|

Hydraulic Station |

4 Kw, with 12Mpa pressure |

|

|

Electric System |

PLC Brand |

Panasonic |

|

Converter |

Yaskawa |

|

|

Encoder |

Omron |

|

|

Reducer |

Guomao |

|

|

Touch Screen |

MCGS |

|

|

Electrical parts |

Schneider |

|

|

Run-out Table |

Type |

No power with passive rollers |

|

Function |

Support the profiles after cutting |

|

|

Machine |

Dimension |

3.5m*0.5m*0.8m (L*W*H) |

|

Weight |

3.5 Tons |

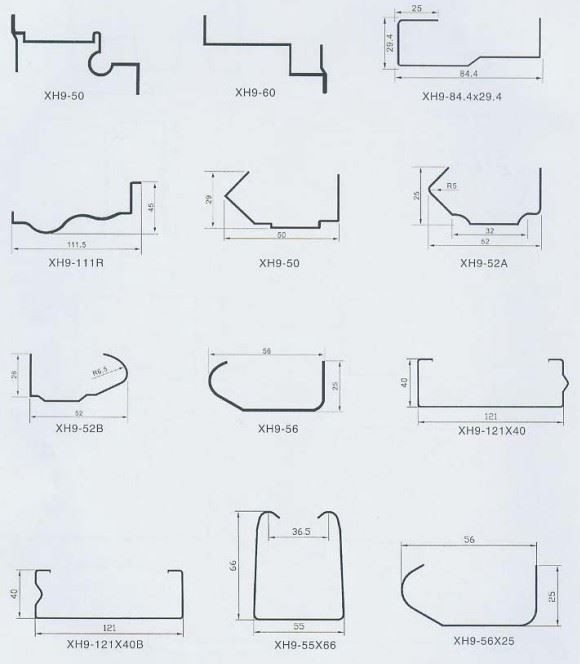

Garage Door Guide Rail Sketch

After Sale Service

A. Foreign debugging

If you need, we will arrange our professional engineers to help you install and debug the machines well. Buyer should pay $80 per day.

B. Guarantee period

The warranty will be maintenance, maintain in the guarantee period of 18 months starting from delivery. Because of the quality of equipment during guarantee period, we will provide the parts free of charges, which is in the conditions of correct operation. (Natural disasters or factors which can’t forced by human are excluded).

C. Lifetime services

Life time services to every customer.

Container Packing

Why choose us?

- We have a team of experienced engineers who design and develop Profile Forming Machines that meet your exact requirements.

- Moreover, the company stays unique among its competitors due to its superior standard of quality in production, and its efficiency and flexibility in business support.

- You can always rely on our Profile Forming Machines for their outstanding performance and durability.

- Sincerely hope we are growing up together with our prospects all over the environment.

- We are committed to delivering the best Profile Forming Machines to our customers at the most competitive prices.

- With the enterprise spirit of unity and hard work, all staffs of our company strive to provide more value-added Cold Roll Forming Machinery and services to our customers.

- We offer a range of Profile Forming Machines with different processing capabilities, catering to different industries.

- The purpose of our factory: "Quality is the cornerstone of the survival of an enterprise, and credibility is the guarantee for the development of the enterprise". Sincerely welcome new and old customers at home and abroad to visit, negotiate business and cooperate sincerely.

- We are constantly upgrading and improving our Profile Forming Machines to provide innovative solutions to the industry.

- Your satisfaction is our high pursuit. We hope to be your good business partner. In short, we are: 'starting from customer requirements and end in customer satisfaction, everything for you'.

Hot Tags: cold roll forming machinery, Steel Wall Angle Forming Machine, Shutter Door Forming Machine, HIgh Speed Purlin Roll Forming Machine, Glazed Tile Roof Sheet Roll Forming Machine, Sheet Metal Forming Machines, Metal Rollfomer