Машина для двухслойной формовки рулонов

Описание

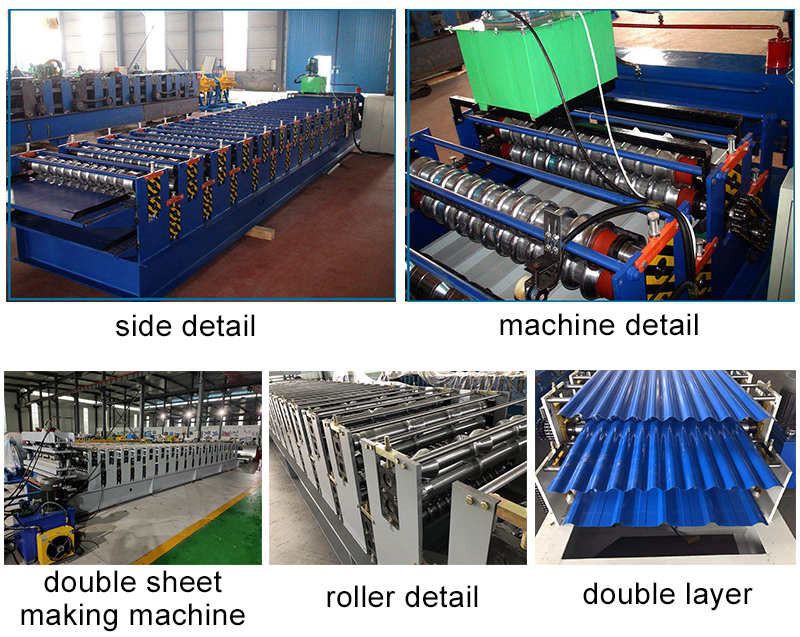

Introducing the Double Layer Roll Forming Machine

In today's world, there are many businesses that require sheet metal for their products. Sheet metal is distributed in various shapes and sizes, and it is cut and molded according to customer requirements. Traditionally, sheet metal was cut with the help of manual hacksaws or saws. However, this process was not only time-consuming but also labor-intensive. Hence, there was a need to put up a faster and more efficient process.

Roll forming machines were then developed, and they are currently used for mass production of different sheet metal parts. These machines are capable of forming and shaping different metal sheets using a series of rollers.

Double Layer Roll Forming Machine is one such machine that has been developed to cater to the manufacturing demands of modern-day businesses. It is one of the most advanced machines in the market which can manufacture a wide range of metal sheet profiles. The machine can produce sheets of different widths and thicknesses with great precision and consistency. As such, it is a perfect investment for businesses that require mass production of sheet metal profiles.

So what makes the Double Layer Roll Forming Machine unique?

1. High-speed production

The double layer roll forming machine is known for its high-speed production capabilities. Its advanced technology allows it to produce sheets with great accuracy while maintaining high production speeds. With this machine, you can produce more sheet metal parts in a shorter time frame.

2. Automatic production process

The double layer roll forming machine is an automatic machine that requires minimal operator intervention. The entire manufacturing process is computerized, reducing human intervention and increasing production speed. The machine can run 24 hours a day, every day of the week, leading to increased profits for manufacturers.

3. Wide range of applications

The Double Layer Roll Forming Machine can produce a wide range of metal profiles including corrugated, trapezoidal, glazed tile, and others. Hence, it is suitable for use in multiple industries such as construction, automobile, electrical, and manufacturing industries.

4. Easy to operate

The machine has a user-friendly interface despite being highly automated. It does not require the operator to have advanced technical knowledge to operate it. The machine's software can be configured to suit different production requirements, ensuring its usage in different kinds of businesses.

5. Durable and robust

The Double Layer Roll Forming Machine is made up of high-quality materials that make it robust and durable. With proper maintenance, it can serve your business for years without breaking down. Its robustness ensures that your business continues to meet production demands without too much downtime.

In conclusion

The Double Layer Roll Forming Machine is an essential device for businesses that require mass production of metal sheet profiles. It is a highly efficient and flexible machine that can produce sheets of different widths and thicknesses with great precision and consistency. With a wide range of applications, easy operation, and high-speed production, it is an investment that will yield long-term benefits for businesses. Furthermore, with its durability and robustness, the machine ensures that it can serve you well for years with proper maintenance. Feel free to reach us if you are interested in purchasing the Double Layer Roll Forming Machine or if you need any further information.

Introduction

Double Layer Roll Forming Machine is a mechanical equipment for producing color steel tiles, which provides strong support for the construction industry. The construction of many color steel houses will use the color steel tiles of different shapes and colors produced by this equipment, which enriches our building materials market and improves the economic construction of related industries. Compared with other traditional equipment, the biggest feature of this product is that it adopts a double-layer production design. Although its operation difficulty is a little higher than that of a single-layer roller press, its production efficiency is very high. You can choose different types of molds to complete the production of different embossed sheets.

Features

1. Double Layer Roll Forming Machine adopts a new double-layer planning design, which can realize one machine with two functions. The smaller footprint not only makes transportation easier but also saves money.

2. The advanced self-control system enables the equipment to realize the information management of production and the automatic control of the unit.

3. The touch screen can clearly display various production data, and the operator can quickly adjust the parameters.

4. The equipment has high compatibility and is very suitable for steel structure workshops, mezzanine roofs, light steel ring sheds and other fields.

A. Uncoiler: mandrel expand type

Specification:

1. Size of appearance: 2900mm (L) x1280mm (W) x1730mm (H) ---Approx.

2. Coil stock-inner dia: 460mm-520mm (max 620mm)

3. Outer dia: 1600mm

4. Width: 1250mm max

5. Loading capacity: 7500kgs max

6. Machine weight: 2080kgs(Approx.)

7. Main motor: 7.5KW, hydraulic station: 3KW (hydraulic motor is not good)

8. Rotating speed: 20m/min max

9. Attached with cooling equipment by air

10. Complete with one set of rotating sensor for automatic production.

11. Complete with a remote control for loading coil.

12. Control box: All of push button, switches pilot lamps, emergency stop switch and in computer system.

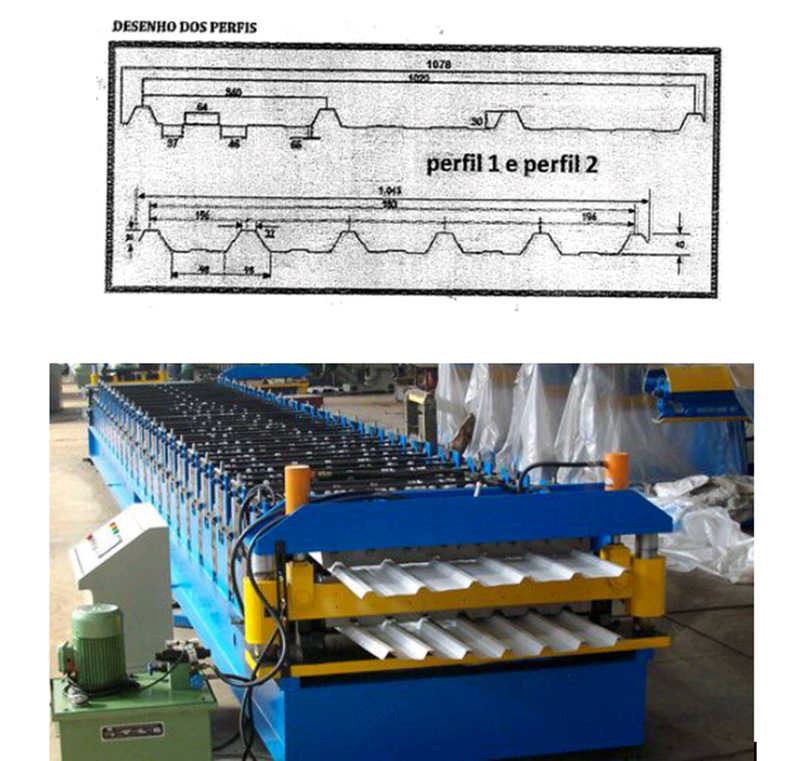

B. Cold Roll Forming Machine

Specification:

1. Machine size (Approx.): 7000mm(L)x1650mm(W)x1050mm(H)

2. Thickness of forming sheet: 0.2mm-0.8mm

3. Forming Speed: 18-20m/min

4. Coil width: 914mm, effective width: 750mm+/-5mm

5. Roll shaft dia: 75mm in 45# steel

6. Roller stand: 21 sets of rollers in SK-2 hard chrome coated.

7. Main motor: 7.5KW

8. Complete with one set of tachometer for automatic production.

9. Attached with one set of runout table.

10. Control box: All of push button switches pilot lamps, emergency stop switch and in computer system with touch screen.

C. Hydraulic Cutting Device

1. Attached with one set of rea-cutter in SKD-11.

2. Attached with one set of pre-cutter in SKD-11.

3. Hydraulic cutting system is controlled by computer and the power is 3KW

Why choose us?

- As a supplier and manufacturer, we offer competitive pricing and exceptional service.

- Our excellent technology and endless pursuit have created the diamond-like quality of our Double Layer Roll Forming Machine and guarantees consistent performance.

- We provide excellent after-sales service to ensure customer satisfaction.

- Our company will provide you with satisfactory service with affordable price and professional manufacturing technology.

- Our goal is to be our customers’ long-term partner and provide continuous support.

- The company will focus on the industry, serve the global industry, and work hard to create a better tomorrow for mankind.

- We have a stringent quality control process to ensure our machines meet the highest standards.

- Through honest management, we have won wide recognition from the market and extensive trust from our customers.

- Our machines perform at a high level, ensuring consistent and reliable results every time.

- In our years of brand development history, we have insisted on building the excellent performance of Double Layer Roll Forming Machine with leading technological strength.

Hot Tags: double layer roll forming machine, Shutter Door Forming Machine, Multi Rib Span Roof Sheet Roll Forming Machine, Metal Rollfomer, Beam Roll Forming Machine, Cold Roll Former, Double Layer Roof Tile Roll Forming Machine