Roof Sheet Roll Forming Machine

Description

Introduction:

The Roof Sheet Roll Forming Machine is a revolutionary product that has been designed and engineered to cater to the growing demand for high-quality roofing solutions. This machine has been manufactured using cutting-edge technology and materials of the highest standard to ensure long-lasting durability and top-notch performance. As a manufacturer based in China, we are proud to offer this product to merchants around the world who are looking for a reliable, efficient, and cost-effective roofing solution.

Features:

The Roof Sheet Roll Forming Machine is packed with features that make it a standout product in the market. Some of its key features include:

1. High Efficiency:

This machine has been designed to produce roofing sheets at an incredibly high rate of speed. It is capable of producing up to 20 meters of roofing sheets per minute, making it an ideal choice for manufacturers who need to produce large volumes of roofing sheets quickly and efficiently.

2. Easy to Operate:

The Roof Sheet Roll Forming Machine has a user-friendly interface that makes it easy to operate. The machine features a touch screen control panel that allows operators to select the desired settings and monitor the production process. Additionally, it has been designed with safety in mind, with multiple safety features that protect operators and ensure that the machine runs smoothly.

3. High Precision:

This machine is capable of producing roofing sheets with a high level of precision. It features a mechanical cutting system that cuts the sheets to the exact size required, ensuring that each sheet is of consistent size and shape.

4. Versatility:

The Roof Sheet Roll Forming Machine is capable of producing a wide range of roofing sheets, including corrugated sheets, trapezoidal sheets, and IBR sheets. This makes it an ideal choice for manufacturers who need to produce different types of roofing sheets to meet the needs of their customers.

5. Low Cost of Production:

This machine has been designed to be highly efficient, reducing the cost of production for manufacturers. It is capable of producing high-quality roofing sheets at a low cost, which makes it an excellent choice for businesses that want to increase their profit margins.

Benefits:

The Roof Sheet Roll Forming Machine offers a range of benefits to merchants who invest in this product. These benefits include:

1. Increased Productivity:

By investing in this machine, manufacturers can significantly increase their productivity. The machine can produce roofing sheets at a much faster rate than traditional methods, allowing businesses to meet the demands of their customers in less time.

2. Improved Quality:

The Roof Sheet Roll Forming Machine is capable of producing high-quality roofing sheets that are consistent in size and shape. This improves the overall quality of the product and increases customer satisfaction.

3. Cost-Effective:

This machine has been designed to be highly cost-effective, reducing the cost of production for manufacturers. By investing in this product, businesses can increase their profit margins and remain competitive in the market.

4. Versatility:

The Roof Sheet Roll Forming Machine is capable of producing a wide range of roofing sheets, making it a versatile solution for manufacturers. This allows businesses to offer a variety of roofing solutions to their customers, increasing their customer base and market reach.

Conclusion:

The Roof Sheet Roll Forming Machine is a top-quality product that has been designed to cater to the needs of manufacturers around the world. With its high efficiency, ease of operation, versatility, and cost-effective nature, this machine is the solution to all your roofing needs. As a manufacturer based in China, we are confident that our product will exceed your expectations and offer the quality and performance that you need to succeed in the market. Contact us today to learn more about our Roof Sheet Roll Forming Machine and how it can benefit your business.

Introduction

This roof sheet roll forming machine can efficiently produce steel roof or wall panels, so it can be widely used in factories, warehouses, office buildings, cold storage, shops, kiosks, temporary housing and other fields. It is equipped with high-performance manual uncoiler, guiding device, roll forming system, cutting device, hydraulic system, PLC control system, etc. to ensure the efficient operation of the whole process. The rollers are made of high quality steel and are surface polished and chrome plated for wear and corrosion resistance. In addition, this machine has major components from several well-known manufacturers, which further ensure long life and stability. If you have your own ideas about the size, specification and layout of the machine, welcome to contact us for customized service at any time.

Details

1. The uncoiler can help the steel coil to be uncoiled automatically. Its inner diameter is 450-508mm and the load capacity is 5T.

2. The guide rod and slider can inform the width and position of the steel plate, and the pre-cut knife can cut the plate before forming to save material.

3. The cutting blade is powered by a hydraulic station, and its material is Cr12 quenched, and there is no waste after cutting.

4. The PLC control system is very easy to operate and use, and it has two calculation modes: automatic and manual.The operator can adjust the production parameters of the roof sheet roll forming machine through this system.

1. Machine Specifications

|

1 |

Coil Type |

Pre-painted coil, Galvanized steel or G500 G550 |

||||

|

2 |

Width |

1220mm or as per client's request |

||||

|

3 |

Thickness Range |

0.2-1mm |

||||

|

4 |

Effective width |

1050mm or as per drawing |

||||

|

|

||||||

|

1 |

Power Requirement |

Voltage |

(380V 50HZ), or according client require |

|||

|

Main Motor power |

5.5kw as per sheet thickness |

|||||

|

Cutter power |

5.5kw as per sheet thickness |

|||||

|

2 |

Forming speed |

10-15m/min |

|

|||

|

3 |

Forming stations |

13 rows, as per finial machine |

||||

|

4 |

Main Frame |

300H beam |

||||

|

5 |

Sidewall thickness |

14mm |

||||

|

6 |

Forming shaft diameter |

70mm 0.01mm-0.03mm (Grinding) |

||||

|

7 |

Chain |

1inch chain drive or as per design |

||||

|

8 |

Type of cutting |

Roll formed and length-set cutting |

||||

|

9 |

Control system |

PLC control |

||||

|

10 |

Install dimension (depend on the final design) |

7.4m 1.5m 1.3m |

||||

|

11 |

Total weight (Approx) |

3.5T |

||||

|

12 |

Roller material |

High grade 45# steel, hard chrome plated |

||||

|

13 |

Feeding system |

Guide type |

||||

|

14 |

Cutting blade |

Cr12 |

||||

|

15 |

Frequency changer |

Delta |

||||

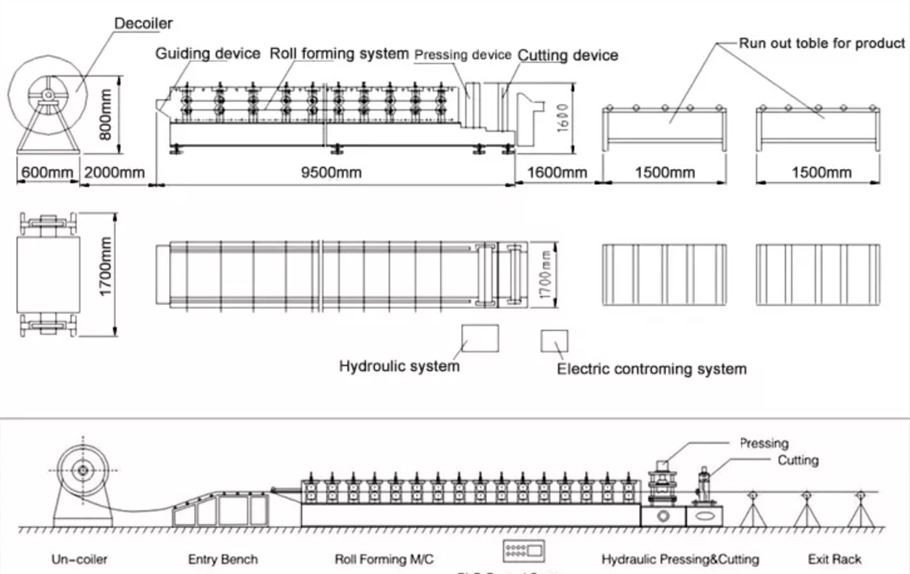

2. Process Drawing

Why choose us?

- Our metal roll forming machines are designed to be highly productive and cost-effective.

- The mission of the enterprise reflects the commitment of the enterprise to itself and the society, and is the meaning and value of the existence of the enterprise.

- Our machines are easy to use and require minimal maintenance, saving our customers time and money.

- Our company is a Roof Sheet Roll Forming Machine manufacturer integrating R&D, manufacturing, marketing and service.

- Our metal roll forming machines are durable and reliable, ensuring long-term stability and cost-effectiveness.

- With the R&D concept of improving the quality and the continuous innovation of the R&D system, the company is proactive and continuously develops and grows.

- We have a stringent quality control process to ensure our machines meet the highest standards.

- We insist on the principle of "respecting people, trusting people and understanding people", so that employees feel that they can develop here.

- We have a reliable and efficient supply chain, ensuring timely delivery of our products.

- In today's rapidly changing economic environment, our company tries to uncover a new chapter in China based on our local and extended international.

Hot Tags: roof sheet roll forming machine, Steel Silo Making Machine, Metal Roof Forming Machine, Forming Machine, Metal Roofing Roll Former, Corrugated Steel Sheet Rollformer, Rain Gutter Roll Forming Machine