Floor Deck Roll Forming Machine

Description

Floor Deck Roll Forming Machine: High Quality and Efficiency for Optimal Results

As a professional manufacturer situated in China, we are proud to present our Floor Deck Roll Forming Machine, an exceptional solution for your construction needs. This system is designed to provide high-quality results while optimizing efficiency, durability, and performance on various floor deck materials. Whether you need it for your personal projects or business requirements, our Floor Deck Roll Forming Machine is built to give you the best value for your investment.

Here are the key attributes and benefits of our Floor Deck Roll Forming Machine:

1. High precision of the product

We understand the importance of producing accurate and precise results, particularly when it comes to construction. That is why our Floor Deck Roll Forming Machine is engineered with high-accuracy components to ensure that the final product meets your expectations. Our CNC technology enables us to regulate the machine’s position and speed to provide high standards of accuracy, making it perfect for bulk or individual production.

2. Durable, reliable and long-lasting

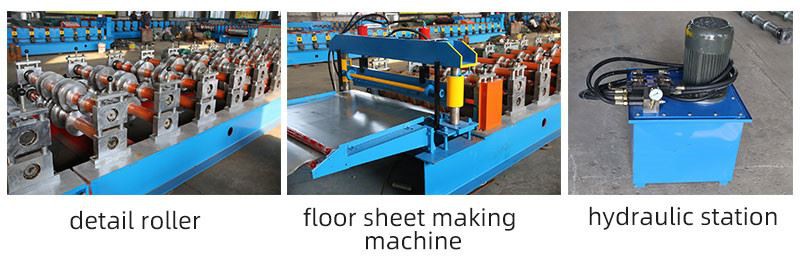

Our Floor Deck Roll Forming Machine is designed with high-strength, robust materials to ensure optimal longevity and durability over extended periods of use. The machine frame is made of high-quality steel or iron, while the rollers are made from materials such as chrome, nickel or polished steel, which can endure high stress, deformation or wear.

3. Versatile, flexible and adaptable

Our Floor Deck Roll Forming Machine can produce an extensive range of floor deck profiles, which makes it a flexible and adaptable solution for your varying business or project demands. Whether you need trapezoidal, corrugated, or even specialized profile designs, our machine can cater to your preferences to ensure that your project goals are met.

4. User-friendly and low maintenance

The Floor Deck Roll Forming Machine comes with a user-friendly interface, enabling easy operation and productivity. Our experts will provide you with a comprehensive manual and support services to ensure exceptional results. Additionally, our machine is simple to maintain, requiring only minimum lubrication and regular cleaning, which minimizes downtime or disruption of your business operations.

5. High productivity resulting from low waste

With our Floor Deck Roll Forming Machine, you can achieve high productivity while minimizing waste. Our roll forming technology reduces material wastage while generating high-quality results for optimal utilization of resources. Your production and project efficiency will also be enhanced, thanks to its automatic cutting and feeding systems, which will ensure smooth workflow and minimal interruptions.

6. Cost-effective solution

As a result of our professionalism, expertise, and advanced technology, we provide a cost-effective solution to meet your production goals. Our Floor Deck Roll Forming Machine is versatile and provides exceptional value for your investment. You can expect a longer lifespan and lower maintenance costs compared to other floor deck roll formers in today's market.

In conclusion, our Floor Deck Roll Forming Machine is a high-quality and efficient solution that caters to the evolving demands of the construction industry. With our experience and expertise, we ensure that your goals are met, whether you're a small company or a large enterprise. Contact us today, and let our experts guide you through choosing a Floor Deck Roll Forming Machine that matches your specific business needs.

Introduction

This floor deck roll forming machine is a high-performance equipment designed and manufactured by us based on advanced technology. For many customers with low investment costs, it is an ideal solution to improve production efficiency and increase economic benefits. In terms of appearance, this machine has a compact structure and a good surface finish, so it has high stability and is easy to clean. In terms of performance, it is equipped with high-precision components to ensure the high quality of the final product, and an easy-to-operate control system to simplify the operation process. Most importantly, we can provide every customer with a full range of support from pre-sales to after-sales to help solve any problems. Welcome customers in need to come to inquiry!

Features

1. This machine is made of high-strength metal material, designed to ensure excellent durability, resistance to deformation and wear resistance.

2. Whether it is trapezoidal, corrugated, or special profiles, this machine can easily meet their mass production needs.

3. The advanced control system is very simple and easy to learn, through which operators can adjust multiple production parameters to achieve the purpose of improving production efficiency.

4. This floor deck roll forming machine is very easy to maintain and also has a very low failure rate because its main components are from well-known suppliers at home and abroad.

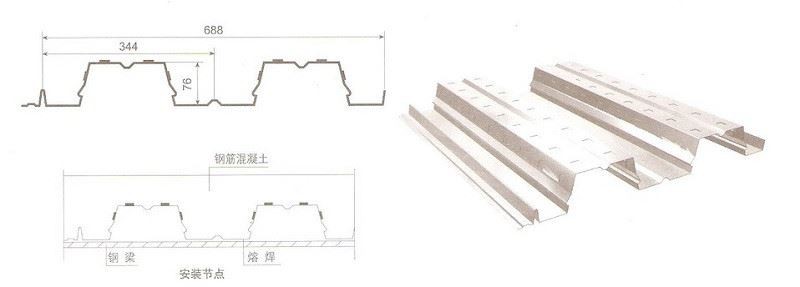

Profile Drawing

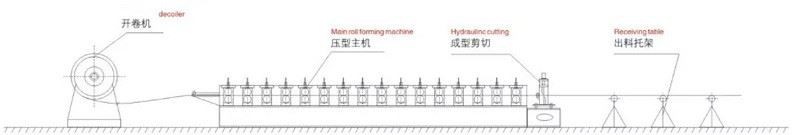

Working Process

|

Main Forming machine |

Forming stations |

22 stations |

|

Shaft diameter |

80mm |

|

|

Machine stand |

Individual Arch Plate |

|

|

Machine frame |

Steel plate welded |

|

|

Roller material |

45#steel |

|

|

Shaft material |

45# steel with quenching and tempering |

|

|

Working speed |

0-15m/min |

|

|

Transport |

By chain |

|

|

Power of main machine |

15kw |

|

|

Voltage |

380V-50HZ-3P (as required) |

|

|

Machine dimension |

13*1. 5*1. 2m |

|

Manual decoiler |

Inner diameter: |

450-50mm |

|

|

Outer diameter: |

1500mm |

|

Max Coil width: |

1500mm |

|

|

Capacity: |

5-10T |

|

|

Decoiler dimension: |

1. 5*1. 5*1. 5m |

|

|

Decoiler weight: |

367KGS |

|

|

Quantity: |

1 SET |

|

|

Usage: |

It is used to support the steel coil and uncoil it in the form of a turntable. Passive uncoil pulled by roll forming system. |

|

|

PLC |

Language |

English, Chinese, Spanish and Russian |

|

|

Programmable setting of contour length and number, calculation mode has two modes: automatic and manual. The system is easy to operate and use. |

|

|

Hydraulic System: Oil pump |

Power |

4kw |

|

|

Hydraulic oil: |

46# hydraulic oil |

|

Working pressure: |

12-16Mpa adjustable |

|

|

Solenoid valve: |

1 groups |

|

|

Collection Table |

Main framework adopts welded steel and supported roller, used for transmit and collect the finished products. |

|

|

|

||

Why choose us?

- We offer comprehensive solutions to meet our customers’ needs and exceed their expectations.

- We have formed a business reorganization master planning scheme and development concept, and the master planning scheme has clearly changed from focusing on scale to focusing on quality and efficiency.

- Our machines are versatile and can be used to produce a wide range of products.

- Our company pays attention to the production cost, quality and marketability of our Floor Deck Roll Forming Machine.

- Our machines are designed to optimize performance and reduce waste.

- The company focuses on the cultivation of innovative capabilities, and actively develops and applies advanced manufacturing and energy-saving and environmentally friendly technologies.

- Our machines are manufactured using the latest technology and advanced techniques.

- At the beginning of its establishment, our company has set up a dedicated R&D department, owning comprehensive development capabilities and possessing a number of advanced technologies.

- We offer quick and efficient delivery of our products to reduce downtime and increase productivity.

- Since the launch of our Floor Deck Roll Forming Machine, it has been favored and praised by customers because of its superior performance.

Hot Tags: floor deck roll forming machine, Forming Machine, Roof Roll Former, Shutter Door Roll Forming Machine, Roofing Sheet Making Machine, Shelf Box Roll Forming Machine, Cold Roll Former