Rain Gutter Roll Forming Machine

Description

Introducing the Rain Gutter Roll Forming Machine – A Revolutionary Product for Ingenuous Merchants

Rain gutters are an essential part of any building, as they help protect it from rainwater damage. A well-installed, sturdy gutter system can redirect rainwater and prevent it from pooling on the roof or around the foundation, causing damage. Whether it is a residential or commercial building, it requires rain gutters to protect it from potential water damage.

What is a Roll Forming Machine?

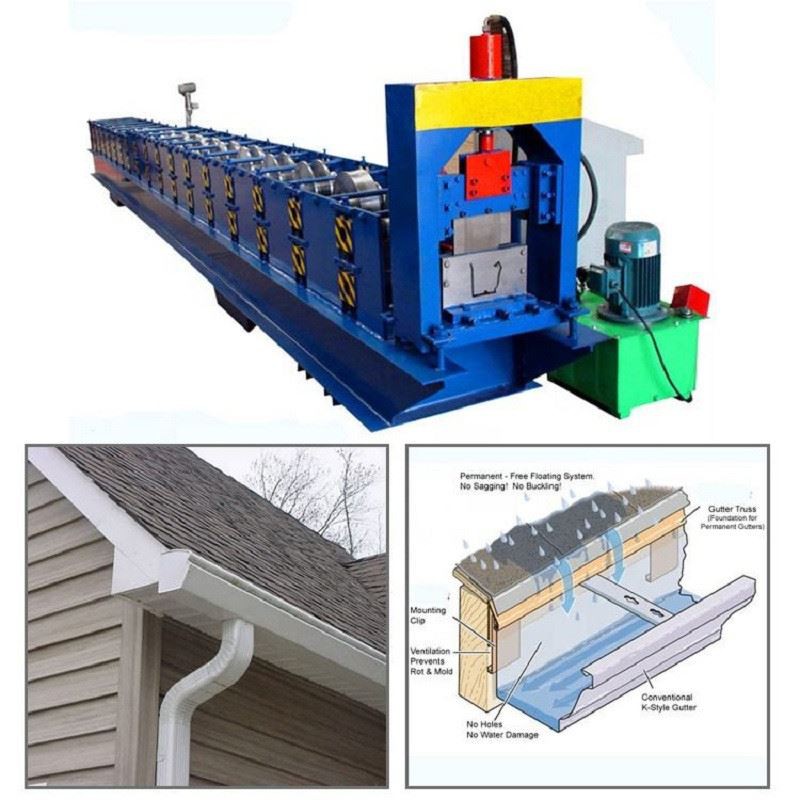

A roll forming machine is a mechanical equipment that enables a manufacturer to produce quality metal profiles of various sizes and shapes. Such profiles are generated through the process of rolling, wherein the material is shaped into a continuous cross-section.

A Rain Gutter Roll Forming Machine is designed to create seamless, custom-made rain gutters, making it easier for manufacturers to meet client needs. The most significant benefit of the machine is that it can produce gutters of different shapes, sizes, and thicknesses as required.

The Rain Gutter Roll Forming Machine: Its Features and Benefits

Our Rain Gutter Roll Forming Machine boasts several features and benefits that make it the perfect product for potential merchants. These include:

1. High-Performance and Efficiency

Our roll forming machines are engineered to offer high performance, efficiency, and precision. The machine can produce rain gutters of different materials such as aluminum, copper, and steel, and in different thicknesses according to client demand. As well, with CNC forming and cutting technology, the machine can produce accurate and precise profiles.

2. High-Quality and Durable Materials

We only use high-quality materials that guarantee the longevity and durability of our products. The main component of the machine is made of high-quality steel, ensuring that the machine is sturdy and long-lasting.

3. Versatility and Flexibility

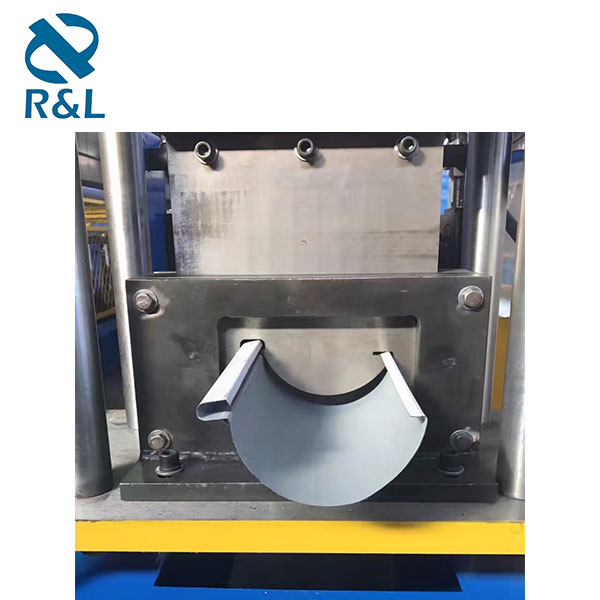

The machine's versatility and flexibility come in handy when producing rain gutters of different styles and designs. It can smoothly produce K-style, half-round, and other custom profiles upon request. The Roll-Forming Machine also offers the flexibility of on-site adjustments, readily adapting to variations of the materials thicknesses.

4. User-Friendly

Our Rain Gutter Roll Forming Machine is user-friendly, and the operator can quickly learn to operate it using the manual or the automatic control, depending on your preferences. It is easy to install and use, with a user-friendly interface that makes it simple to adjust and operate the machine accurately.

5. Cost-Effective

Our machine is designed to enable mass production and in large quantities, enhancing cost efficiencies. The product also has a low rejection rate, reducing the expenses associated with manufacturing faults or waste. As well, our roll forming machine produces pre-measured lengths of gutters, reducing the amount of waste material to a minimum.

6. Reduced Labor Costs

Using our machine eliminates the need for manual labor, minimizing the cost of wages and the risk of error or poor production quality. The machine automates the process and increases production rates, enabling manufacturers to focus on other aspects of the business, such as customer satisfaction, sales, and marketing.

7. Improved Productivity

The use of a Roll Forming Machine in production processes has a direct positive impact on efficiency and productivity. Manufacturers can produce more gutters in less time and with less energy, achieving higher profits.

Conclusion

In summary, a Rain Gutter Roll Forming Machine is an essential addition for manufacturers focused on providing high-performance rain gutters. The machine produces gutters of different shapes, sizes, and thicknesses and is built with precision, efficiency, and quality in mind.

The benefits outlined above, including user-friendliness, cost-effectiveness, and improved productivity, make it the most attractive product on the market. Therefore, if you are a manufacturer looking for ways to improve your productivity and reduce costs, consider investing in our Rain Gutter Roll Forming Machine.

Introduction

Rain gutters can play an important role in buildings by diverting the flow of rainwater to prevent it from accumulating and causing damage to the building. This rain gutter roll forming machine is specially designed for the production of rain gutters, which has many advantages. First, it enables the efficient and flexible production of gutters of different shapes, sizes and thicknesses for a wide range of applications. Secondly, advanced CNC forming and cutting technology can effectively ensure the precision of each rain gutter. Most importantly, this machine can bring extremely high economic benefits because it can carry out large-scale production with lower energy consumption, and can also reduce labor costs and effectively reduce production errors caused by labor.

Features

1. The user-friendly operation interface is clear at a glance, so it has almost no difficulty in operation, which means that workers do not need a lot of training.

2. The structure of this machine has been carefully designed with high stability. The metal body has excellent corrosion resistance and deformation resistance.

3. For rain gutters of different materials and shapes, this rain gutter roll forming machine can easily meet their diverse production needs.

4. This machine is very easy to operate, and the operation manual and technical guidance will be provided to every customer.

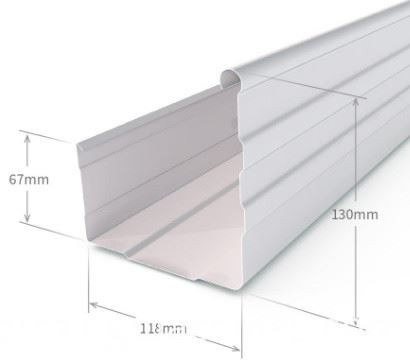

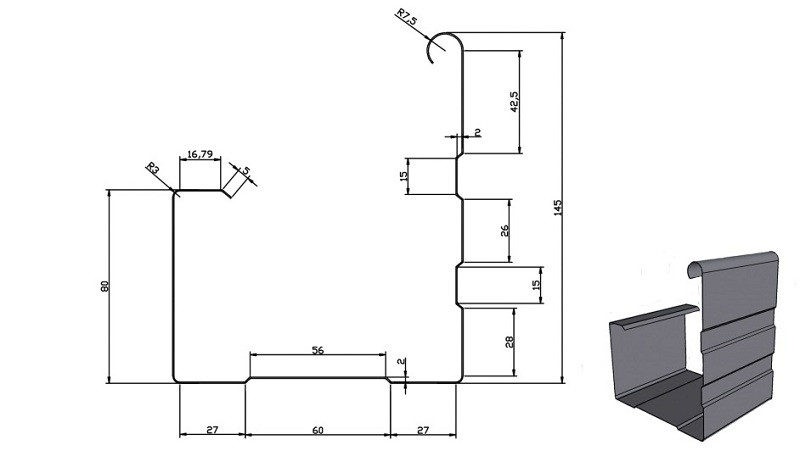

Here is some sizes of high front gutter

Parameters:

|

1 |

Feeding material |

Color Steel Coil, aluminum, GI, PPGI |

|

2 |

Material thickness |

0.2~1mm |

|

3 |

Material yield stress |

230~550mpa |

|

4 |

Feeding width |

As per need |

|

5 |

Forming speed |

8~25m/min |

|

6 |

Cutter material |

cr12 |

|

7 |

Roller material |

45# steel with chrome treatment |

|

8 |

Cr plating thickness |

0.05mm |

|

9 |

Roller station |

11 pieces (according to different profiles) |

|

10 |

Controller |

PLC, touch screen and button |

|

11 |

Hydraulic station motor power |

3kw |

|

12 |

Hydraulic pressure |

12mpa |

|

13 |

Main motor power |

7~8.5kw |

|

14 |

Voltage |

380v 3ph 50hz / as your needs |

|

15 |

Total weight |

6~8t |

|

16 |

Dimension |

10 x 1.5 x 1.5m |

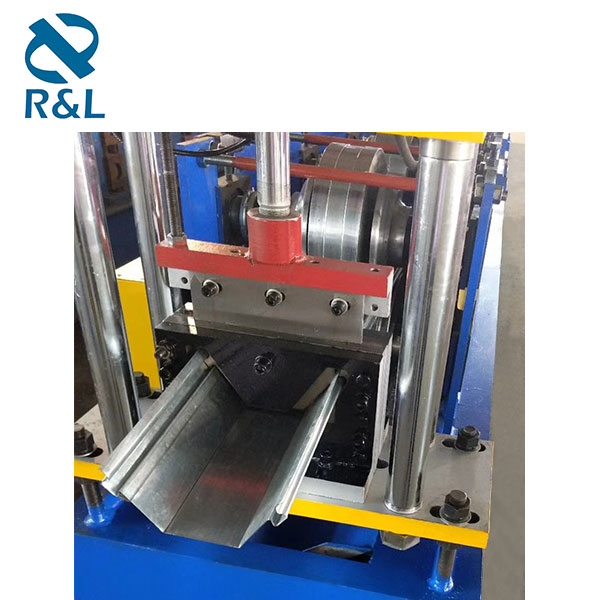

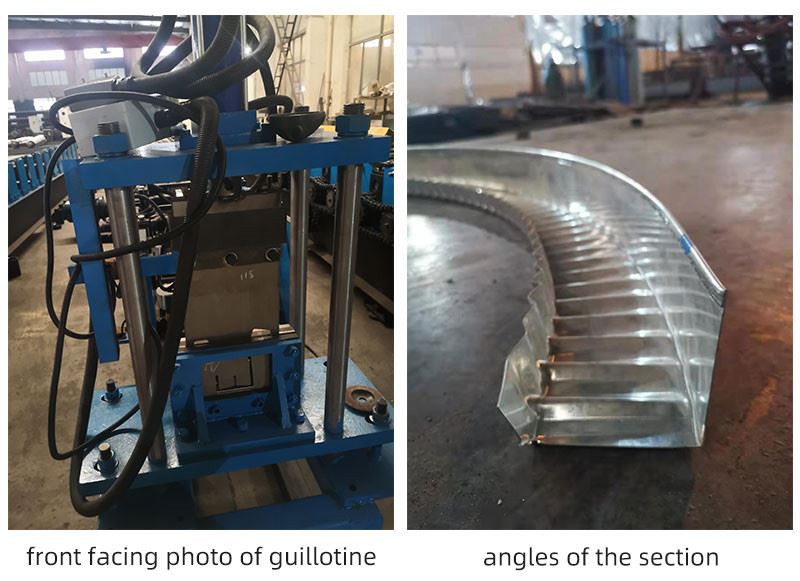

Profile Drawing

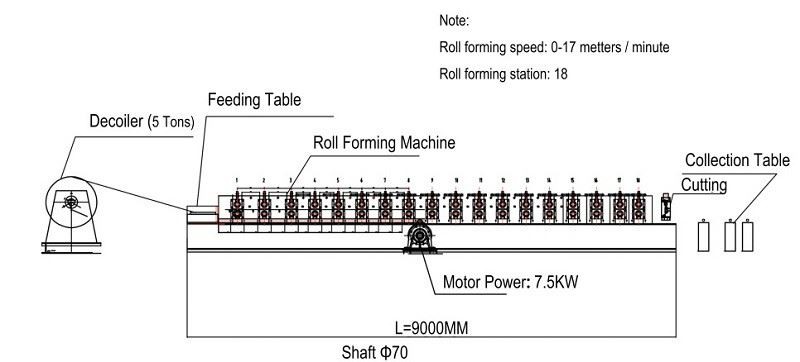

Process Drawing

Why choose us?

- Our goal is to be our customers’ long-term partner and provide continuous support.

- We take the initiative to provide the effective needs of the market and act as a trustworthy and strong partner for our customers.

- Our goal is to build long-term relationships with our customers by providing exceptional service.

- The exceptional quality, perfect belief and endless pursuit make our Rain Gutter Roll Forming Machine a solid and complete force in the marketplace.

- Our machines are designed to reduce labor costs and increase efficiency.

- Each product is precisely test by professional technicians before leaving the factory to ensure the stable performance and high quality of Rain Gutter Roll Forming Machine.

- We are dedicated to delivering the highest quality products and services to our customers.

- We actively listen to our employees, respect their values, provide development platforms, and promote the common growth of employees and the company.

- Our machines perform at a high level, ensuring consistent and reliable results every time.

- We have the industry R&D experience to effectively integrate the analysis results with the industry reality.

Hot Tags: rain gutter roll forming machine, Metal Tile Sheet Making Machine, Cold Roll Forming Machine, Highway Guardrail Machine, Corrugated Steel Water Tank Machine, Purlin Roll Forming Machine, Door Frame Roll Forming Machine