CZ Purlin Roll Forming Machine

Description

Introduction

As a manufacturer located in China, it is our pleasure to present to you our latest product, the CZ Purlin Roll Forming Machine. Our company is dedicated to providing high-quality, innovative products that are designed to make the manufacturing process more efficient, cost-effective, and reliable. In this regard, we have designed the CZ Purlin Roll Forming Machine to be a versatile tool that is essential in the production of high-quality purlins. In this product introduction, we will delve deeper into the various features and benefits that the CZ Purlin Roll Forming Machine offers.

Features

The CZ Purlin Roll Forming Machine is a cutting-edge product that comes with a variety of features, including:

1. Material Thickness Range: The machine can produce purlins between 1.5-3.0mm thicknesses.

2. High-speed Performance: The CZ Purlin Roll Forming Machine has a high-speed capacity of up to 30 meters per minute.

3. Precise Forming: Our machine guarantees accurate and dependable forming. Its cnc control system ensures the machine's accuracy and reliability.

4. Time-Saving: The CZ Purlin Roll Forming Machine is programmed to produce different shapes and sizes, which saves valuable time and increases production efficiency.

5. Safe Production: Our machine includes safety measures such as emergency stop buttons and safety covers.

6. Hydraulic Cutting: Our CZ Purlin Roll Forming Machine incorporates Hydraulic Cutting, which ensures reduced wastage of material and cut-to-length accuracy.

Benefits

The CZ Purlin Roll Forming Machine offers numerous benefits that set it apart from other purlin manufacturing machines on the market. Some of these benefits include:

1. High-quality Purlins: Our machine guarantees high-quality purlins through the precise forming methods and accurate dimensioning, which enhances performance and improves durability.

2. Time Efficiency: Our machine's diverse programming ensures that it is suitable for a range of purlin profiles, which saves time when making complex and different shapes and sizes.

3. Accuracy and Precision: The CNC control system ensures unparalleled accuracy and reliability, which translates to cost savings and improved production efficiency.

4. Durability: Our machine is constructed using high-quality materials that guarantee long-lasting quality, ensuring optimal production with minimal maintenance requirements.

5. Cost-Effective: Our CZ Purlin Roll Forming Machine maximizes production efficiency by reducing the wastage of materials and time spent in production, which directly translates to cost-effectiveness.

Conclusion

In conclusion, the CZ Purlin Roll Forming Machine is a high-quality, innovative tool designed to make purlin manufacturing more efficient, reliable, and cost-effective. With features such as hydraulic cutting, high-speed performance, and precise forming, our machine is guaranteed to provide top-quality purlins. Its benefits, including time efficiency, accuracy, and cost-effectiveness, are unmatched in the market, ensuring that our merchants enjoy optimal production with minimal maintenance requirements. We are confident that the CZ Purlin Roll Forming Machine is the ideal choice for any merchant looking for a reliable and efficient purlin manufacturing solution. For any inquiries or purchase, please feel free to contact us.

Introduction

This CZ purlin roll forming machine can help users efficiently produce high-quality purlins, and it has excellent flexibility and obvious advantages in meeting different production needs in terms of size and shape. Based on high-performance control systems, the accuracy of the final product is effectively guaranteed, while production efficiency can also be improved. In practical applications, this machine can reduce material waste and reduce the labor intensity of workers, which means lower production costs. If you are struggling with an urgent deadline, you may want to purchase this machine as a solution! In after-sales service, we will provide comprehensive technical support to help customers solve various problems encountered during use.

Features

1. This CZ purlin roll forming machine has good durability and cracking resistance because it is made of high-quality metal materials and has undergone multiple surface treatments.

2. Through a simple control system, operators can easily change production parameters, which effectively saves production time while reducing labor intensity.

3. The main components are sourced from internationally renowned suppliers, aiming to ensure long-term stability and durability.

4. The hydraulic cutting device not only reduces material waste but also provides more accurate cutting results.

Requirement of Z and C purlin machine

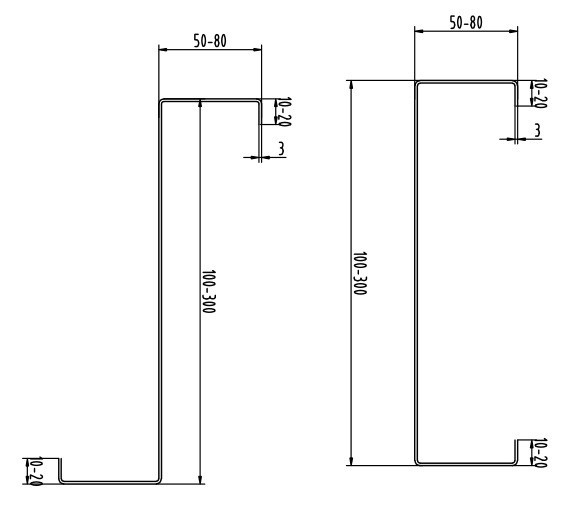

● Z, C type adjustable purlin machine, with hydraulic uncoiler or manual uncoiler.

● Price required for both decoilers.

● C-80mm to 300mm and Z-120mm to 300 purlins adjustable roll forming machine post punching and post cutting.

Machine consists of following parts

● Feeding and Leveling Device

● Rolling Forming System

● Hydraulic Punching & Cutting

● Product outcome support frame

● PLC Control System

When we change from c purlin to z purlin, you only need direction of the rollers to be changed.

Technical Specifications

Approx weight of the machine should be: 9.0MT

Approx dimension of the machine: (length) 10m × (width) 1.4m × (height) 1.8m Decoiler

Decoiler Type: Hydraulic or manual decoiler (price for both)

Weight Capacity of Decoiler: 5.0T

Feeder and leveler Device

This is used for making the material flat before feeding into the forming machine.

Roll Forming System.

● Main Motor Type: 3 Phases motor

● Main Motor Power: 15KW

● Speed of Forming: 10-15m/min

● Material of Roller: GCr15

● 18 Groups Rollers

● Material of main shaft: 40Cr

(The main shaft is grinded & heat treated followed by chrome plating)

●Diameter of Main Shaft: 70mm

Hydraulic Punching & Cutting (Post Roll Forming)

● Punching Type: Hydraulic Punching

● Punching Material: SKD11

● Punching Die: SKD11

● Cutting Type: Hydraulic Cutting

(Separate shearing tolls for 100-200 and for 200-300 may be given)

● Hydraulic Motor: 7.5KW

● Hydraulic Pressure: 20MPaPLC Motion Control System

● Control the quantity & punching length & cutting length automatically

● The machine should be stopped while it is and cutting

Automatic Length measures and quantity counting (precision +-2mm/+-1mm)

● Voltage: 415V, 3 Phase 50HZ

● Size of PLC Control Board (PLC: 700mm (L) × 1000mm (H) × 300mm (W))

● PLC Manufacturer

Support Frame for Outcome

The length of product support frame:6 mtr

Notes:

The machine should be guaranteed for 12 months from the date of installation.

Profile Drawing

Why choose us?

- Our goal is to be our customers’ long-term partner and provide continuous support.

- We realize that if an enterprise does not advance, it will retreat. Therefore, we will continue to move forward with the concept of innovation.

- Our products are made with precision and are of the highest quality.

- We will spare no effort to provide customers with reliable and innovative CZ Purlin Roll Forming Machine products, and contribute to the success of customers as much as possible.

- We offer comprehensive training and support to ensure customers can effectively operate our machines.

- The corporate vision of becoming a respectable and innovative company is the common goal of all our employees.

- We are a Chinese factory offering professional and high-quality metal roll forming machines.

- We look forward to continuing to work with the world's first-class partners to create a new glorious future.

- Our professionals provide expert and reliable service to ensure customer satisfaction.

- The establishment of customer culture and staff learning culture are all our enterprises have been exploring and pursuing.

Hot Tags: cz purlin roll forming machine, Steel Silo Roll Forming Machine, Steel Silo Making Machine, Shutter Door Roll Forming Machine, Shutter Door Rollformer, C Z U Shape Purlin Rollformer, Quick Change Roll Forming Machine