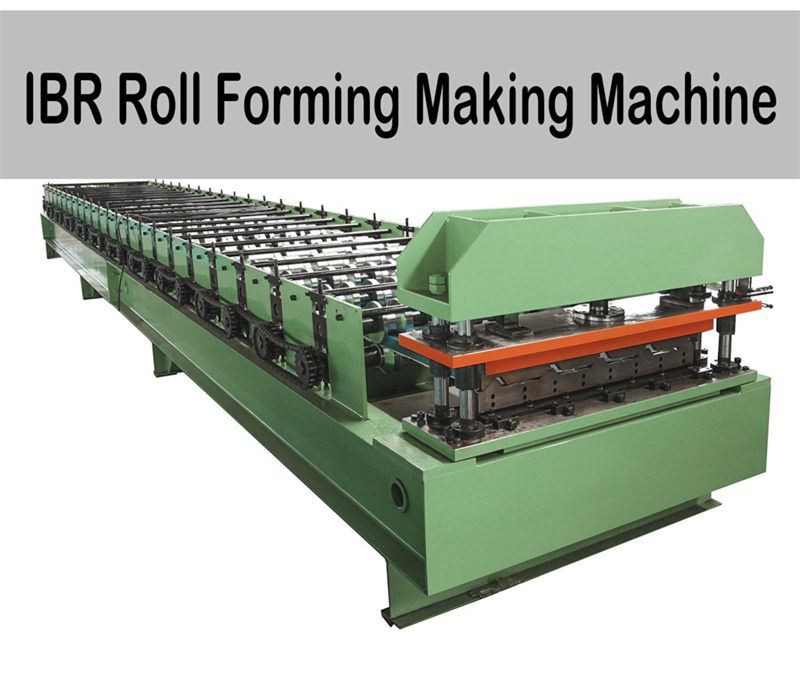

Ibr Roof Sheet Forming Machine

Description

The IBR Roof Sheet Forming Machine is a revolutionary piece of equipment that is designed to improve the efficiency and output of roofing manufacturers. The machine is engineered to produce an ideal shape and profile for use in roofing materials, with exceptional durability and outstanding aesthetics.

As a manufacturer based in China, we take great pride in our commitment to delivering high-quality machines that meet the needs of our clients worldwide. With the IBR Roof Sheet Forming Machine, we aim to enhance the productivity and competitiveness of roofing manufacturers, by providing an advanced and reliable solution for the production of roofing products.

One of the key features of the IBR Roof Sheet Forming Machine is its flexibility, allowing for the production of various types of roofing profiles, such as IBR, corrugated, and other custom-made profiles. This versatility means that regardless of your roofing needs, the IBR Roof Sheet Forming Machine delivers fast, accurate and consistent results, with unmatched precision.

Another significant advantage of the IBR Roof Sheet Forming Machine is its ease of use, which reduces human error and improves the consistency of the final product. The machine's intuitive interface makes it simple for operators to control the different settings and parameters to meet their specific production needs.

The IBR Roof Sheet Forming Machine boasts robust construction, high-quality materials, and cutting-edge technology. This results in a stable, durable, and reliable machine that can withstand the heavy duty of the production process, thus lowering the risk of machine failure and maximizing uptime.

The machine design also takes into consideration the protective measures, such as safety gating, which ensures that the machine can be operated in a safer environment. This feature enables manufacturers to adhere to safety regulations and protect their operators from harm.

Lastly, as a manufacturer committed to environmental responsibility, we have designed our IBR Roof Sheet Forming Machine to operate with less energy and generate less waste. This means that for roofing manufacturers seeking a more sustainable and eco-friendly approach to the production process, the IBR Roof Sheet Forming Machine offers a compelling solution.

In conclusion, our IBR Roof Sheet Forming Machine offers a game-changing solution for roofing manufacturers seeking to elevate their productivity, efficiency, and competitiveness. With its superior flexibility, ease of use, robustness, safety features and eco-friendliness, this machine is a must-have for roofing manufacturers worldwide. We are proud to offer this impressive product that delivers unparalleled results, and we assure you of our commitment to providing the highest quality machines at competitive prices. Contact us today to learn more about the IBR Roof Sheet Forming Machine and to place your order.

Introduction

This Ibr roof sheet forming machine is a highly automated equipment and an ideal solution for meeting the needs of mass production. It is designed and manufactured using high-quality materials and advanced technology, so it can provide more stable and reliable performance under long-term operation. Through a clear operating interface, operators can flexibly adjust various parameters, effectively reducing errors caused by human intervention and improving the dimensional accuracy of the finished product. As a multifunctional device, this machine can meet the production of various shapes of materials such as IBR and ripple. If you are interested in this product, please contact us now! We will provide you with competitive prices.

Features

1. This machine can help users improve production efficiency while improving product quality and reducing waste of raw materials.

2. The exquisite structural design ensures that this machine has excellent durability and does not generate significant noise and vibration.

3. The fault alarm function can assist users in identifying losses and locating the fault location in the event of a sudden fault.

4. This Ibr roof sheet forming machine fully complies with international safety standards, which means that operators can work under safer conditions.

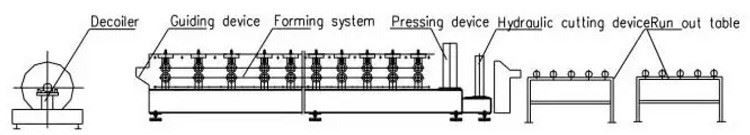

1. Supplying Components of Complete Machine

No. | Description | Quantity (set) | One complete part |

1 | 5Tmanual decoiler | 1 | |

2 | Guiding device | 1 | |

3 | Pre-cutter | 1 | |

4 | Forming system | 1 | |

5 | Transmission system | 1 | |

6 | Hydraulic guillotine | 2 | |

7 | Collection table | 2 | |

8 | Hydraulic station | 1 | |

9 | Control box | 1 | |

10 | Spare parts and tools | 1 | Attaching list |

2. General Technical Information

Main motor power | 5.5kw |

Roller material | 45# steel with chormed treatment |

Roller shaft material | 45# steel with quenched treatment. |

Working speed | 8-12 m/min (Cutting is included) |

Length of machine | 7500*1650*1500mm |

Structure | Middle plate welded frame structure |

Frame | 350 H steel with diagonal bracing |

Drive mode | By double chains drive method |

Control method | PLC control system |

PLC | Delta Chinese good brand for good using |

Hydraulic station | 4.5kw with cooling fan system |

Cutting method | Hydraulic cutting |

Cutter materia | GCr12 chromed and quenched for good hardness and using |

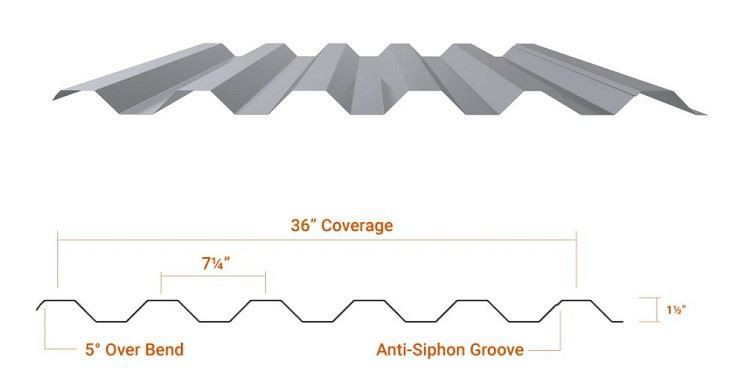

Profile Drawing

Process Drawing

Why choose us?

- Our machines are designed to reduce labor costs and increase efficiency.

- Our company has established long-term cooperative relations with many well-known enterprises and won certain public praise. We are committed to building the company into a leading enterprise in the industry with the corporate goal of "becoming more refined, more specialized and stronger".

- We take pride in delivering the best quality metal roll forming machines to customers globally.

- With the rapid development of our company, the variety and output of our Ibr Roof Sheet Forming Machine have been greatly expanded and improved.

- We provide expert advice and support to ensure our customers make informed decisions.

- We have been taking products as the core and market positioning as the goal to provide customers with one-stop integrated services of product strategy, research, design and product promotion strategy.

- Our experts can provide customized solutions to meet even the most complex requirements.

- It not only saves costs, but also increases economic and social benefits. A green, environmentally friendly, energy-saving and healthy recycling industry has been formed.

- We provide excellent after-sales service to ensure customer satisfaction.

- At the same time, we actively absorb advanced technology, use cost advantages, and combine independent innovation to develop a variety of new products.

Hot Tags: ibr roof sheet forming machine, Ibr Roof Sheet Forming Machine, Roll Forming Machine, Pallet Rack Roll Forming Machine, CU Omega Purlin Roll Forming Machine, Steel Water Tank Rollformer, Self Lock Roof Panel Roll Forming Machine