Deck Roll Forming Machine

Description

Deck Roll Forming Machine Introduction

Are you looking for a top-quality roll forming machine for producing high-quality roof decks for building projects? Look no further than our deck roll forming machine. This machine is the perfect investment for any construction company, metal fabrication factory or roofing materials supplier looking to produce top-notch roof decks that can withstand harsh weather conditions such as heavy rains, snow, hail, and extreme heat.

At [company name], we are a leading manufacturer of metal forming machines, including deck roll forming machines. We are based in China and have been supplying high-end machines to merchants worldwide for years. Our machines are compatible with various types of metals, including steel, galvanized steel, aluminum, and other alloys. The machines are user-friendly, easy to install, and require minimal maintenance, making them perfect for both small-scale and large-scale production.

Features and Benefits of Our Deck Roll Forming Machine

Below are some of the reasons why you should choose our deck roll forming machine:

1. High-Quality Production

Our deck roll forming machine is designed to produce high-quality roof decks with minimal wastage. By using our machine, you can produce strong and durable roof decks that will last longer without needing repairs. The machine allows for the production of custom lengths, widths, and profiles of roof decks, depending on your clients' specific requirements.

2. Fast Production Speeds

With our deck roll forming machine, you can produce large quantities of roofing decks quickly. This machine can produce up to 12 sheet profiles in one minute, depending on the complexity of the profile. This speed is ideal for large-scale production, especially when deadlines are tight.

3. Easy to Use and Maintain

Our machine features advanced technology that makes production easy. You don't need to have extensive experience or technical skills to operate the machine. The machine comes with a user manual to guide you through the installation and the operational steps. Our machines are also designed for minimal maintenance, which reduces downtime and ensures that you meet your deadlines.

4. Durable and Long-Lasting

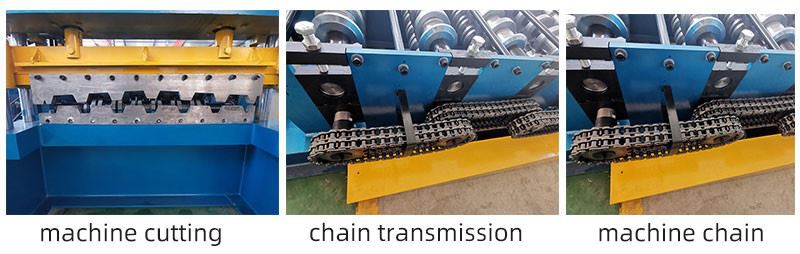

Our deck roll forming machine is made of high-quality materials that can withstand the rigors of heavy production. The mainframe is made of welded structural steel that can handle high levels of stress and strain without cracking or bending. The forming rollers are made of heat-treated steel, which makes them durable and long-lasting.

5. Cost-Effective Investment

Investing in our deck roll forming machine is cost-effective in the long run. The machine requires minimal maintenance, meaning you can save on labor costs. Our machines' energy-efficient technology allows you to run the machine for hours without incurring high energy bills. The machine's durability is also another cost-effective factor as you don't need to replace the machine in the short term.

6. Customizable Designs and Sizes

Our deck roll forming machine can produce custom-made roof decks with different designs and sizes. You can create unique designs that meet your client's specific requirements. The machine is flexible, allowing you to produce varying profiles, widths, and lengths of roofing decks.

7. Excellent Customer Service

We offer excellent customer service to our clients worldwide. If you have any questions or concerns regarding our deck roll forming machine, our technical support team is always available to offer help. We also offer warranty services on our machines, meaning that you can trust our products as a long-term solution.

Conclusion

At [company name], we offer the best deck roll forming machine in the market. Our machines are designed to produce high-quality and durable roof decks that meet your clients' specific requirements. Our machines' features are cost-effective, easy to use, and durable, meaning that investing in one is a valuable investment. Contact us today, and we will be happy to provide more information on our products and services.

Introduction

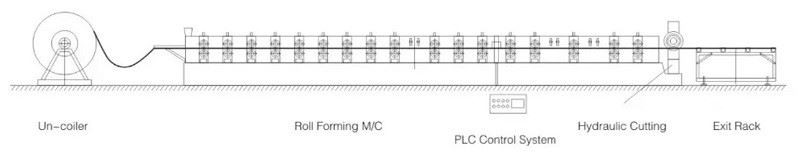

Deck Roll Forming Machine is an automatic equipment that can bend metal sheet materials such as coils and strips through multi-pass forming rolls to form profiles with specific cross-sections. The technology of this machine is suitable for the production of large batches of workpieces with equal cross-sections and long lengths, and the economic benefits are also huge. At the same time, it can also be integrated with various processes to form a continuous production line. Treated sheet metal is great for things like roof decks and also bonds well with concrete, increasing the strength and reducing the weight of a building.

Features

1. Although the Deck Roll Forming Machine is small in size, its forming speed can reach 1-15 m/min, which not only has high efficiency but also occupies a small workshop space.

2. The automatic control system makes the feeding process smooth and saves manpower while greatly improving efficiency.

3. The handsome high-strength steel frame is polished so it's rounded and smooth. The characteristics of wear resistance and not easy to rust make it suitable for more harsh production environments.

4. The computer-controlled production process is beneficial to ensure that the appearance of the color plate is more even and uniform, and the strength is higher, so it is more suitable for scenes such as industrial and civil buildings.

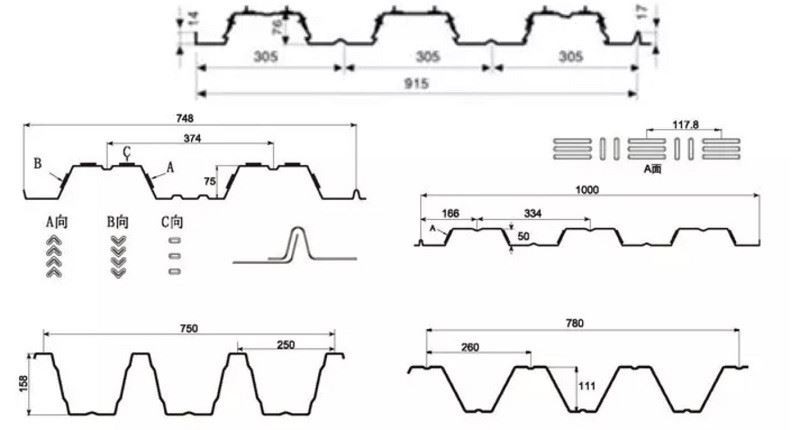

Profile Drawing

Process Drawing

|

Material width |

925-1250 |

|

Material thickness |

0.8-1.5mm |

|

Decoiler |

manual |

|

Loading weight |

5 -6 tons |

|

Forming speed |

1-15m/min (cutting is included |

|

Forming station |

26 stations or as per design |

|

Shaft material |

45# high quality steel |

|

Shaft diameter |

76mm |

|

Roller material |

45# high quality steel, hard chrome coated 0.05mm |

|

Transmission |

Chains-sprocket |

|

Main motor power |

2x11kw |

|

Cutting Blade |

Cr12 with quenched treatment 60-62 |

|

Hydraulic power |

4kw |

|

This machine will be automatically measured and cut the length and quantity as per clients set on the PLC touch screen |

|

|

Length cut accuracy |

±1mm |

|

PLC control system |

Omron Japan |

|

Frequency converter |

TAIAN |

|

Screen |

TouchWin |

|

Voltage |

As per request |

|

Overall dimensions |

1600x1500x1300mm |

Why choose us?

- We provide expert advice and support to ensure our customers make informed decisions.

- We believe that only by scientifically grasping the characteristics of the times and improving our core competitiveness through new technology and new Deck Roll Forming Machine can we win the market competition.

- Our machines are easy to use and require minimal maintenance, saving our customers time and money.

- Our concept of knowledge is always thirsty for knowledge, never stopping, continuous improvement and excellence.

- We take pride in producing metal roll forming machines that are durable and reliable.

- We have not only skillful craftsmen in mechanical manufacturing, but also modern manufacturing methods, which are the strong guarantee for stable products.

- We specialize in producing Metal Roll Forming Machines of the highest quality.

- In the years of development, our company has been in line with the customer service first, maintain the faith of quality first and has won the general customer's consistent high praise.

- Our products are built to last and withstand rigorous use.

- We strive to deal with the relationship between scale and efficiency, current development and long-term development as well as the relationship between company development and employee development.

Hot Tags: deck roll forming machine, Rain Gutter Roll Forming Machine, C Shape Purlin Roll Forming Machine, Corrugated Sheet Making Machine, Corrugated Roof Sheeting Machine, Purlin Roll Forming Machine, Rack Upright Roll Forming Machine