Glazed Tile Roll Forming Machine

Description

Introduction

Welcome to our Glazed Tile Roll Forming Machine product introduction. We are a manufacturer based in China, with years of experience and expertise in the creation and production of high-quality roll forming machines. Our Glazed Tile Roll Forming Machine is one of our most popular products, offering a range of benefits to merchants in countries outside of China. In this product introduction, we will be discussing the key features and benefits of our Glazed Tile Roll Forming Machine, and exploring how it can help grow your business.

Features and Benefits

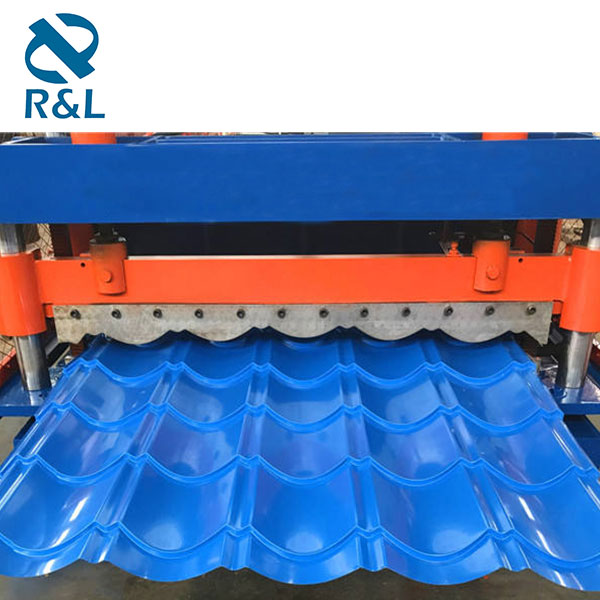

1. High-quality production

Our Glazed Tile Roll Forming Machine is designed and built to the highest standards, using only the best materials and components. It is highly durable, with a sturdy frame that ensures long-lasting, consistent performance. This means that you can rely on our machine to produce high-quality glazed tiles, time and time again.

2. Easy to use

Our Glazed Tile Roll Forming Machine is also incredibly user-friendly. It features a simple, intuitive design that allows you to quickly and easily set up and operate the machine. You don't need to be a skilled technician or have years of experience to use our roll forming machine – it's suitable for people of all levels of expertise.

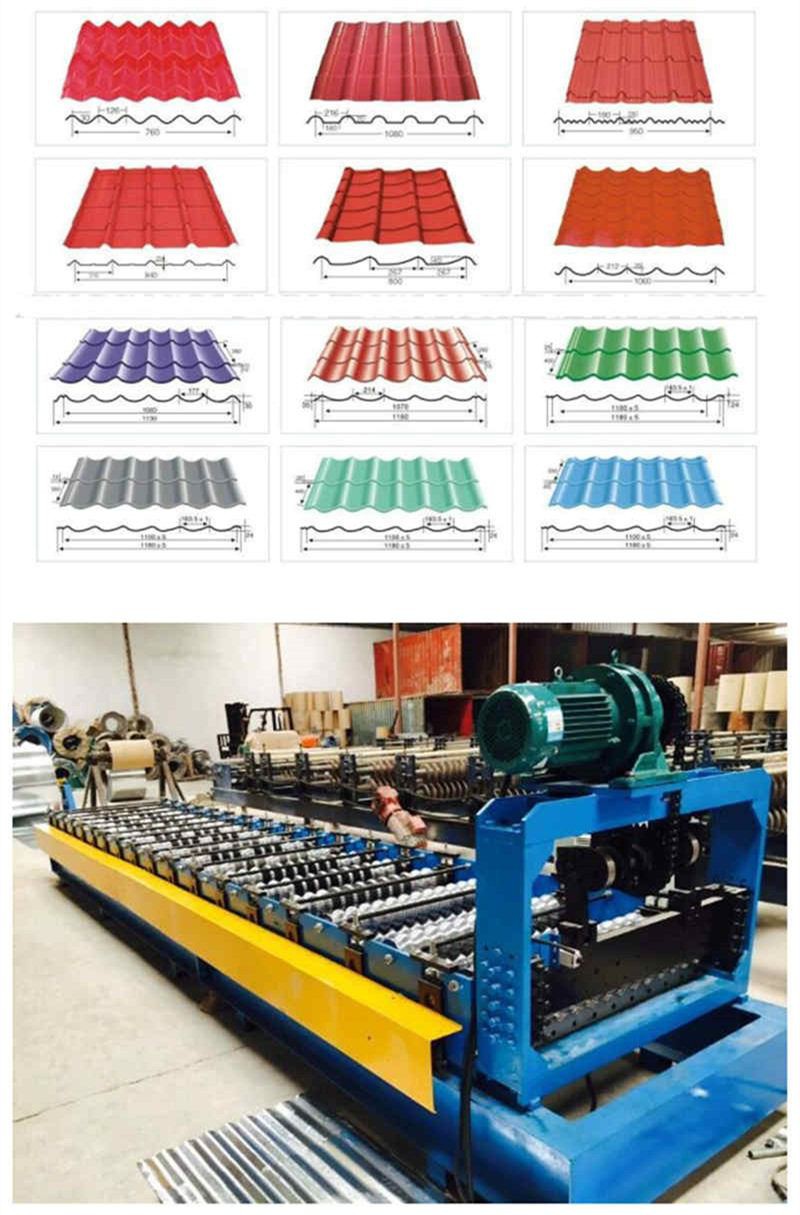

3. Wide range of applications

The Glazed Tile Roll Forming Machine is highly versatile, making it ideal for a wide range of applications. Whether you need to produce tiles for residential or commercial buildings, our machines can help you achieve the perfect finish. Our machine can produce a range of tile sizes and shapes, giving you maximum flexibility when it comes to your production requirements.

4. High speed production

Our Glazed Tile Roll Forming Machine is designed to produce tiles at a high speed, allowing you to quickly and efficiently meet your production targets. This is especially important for businesses that need to produce large volumes of tiles within a short timeframe.

5. Low maintenance

Our Glazed Tile Roll Forming Machine requires minimal maintenance, thanks to its high-quality components and robust design. This means that you can focus on producing tiles, rather than spending time and money on repairs and maintenance. This is a huge advantage for businesses looking to optimize their production processes and minimize downtime.

Conclusion

If you're looking for a high-quality, user-friendly roll forming machine to help grow your business, look no further than our Glazed Tile Roll Forming Machine. With its durable design, wide range of applications and high-speed production capabilities, it's the perfect choice for merchants in countries outside of China. Contact us today to learn more about our Glazed Tile Roll Forming Machine, and see how it can transform your production processes.

Introduction

Color steel tile is a new type of roof tile building material because its main material is steel, so it gets its name. Our Glazed Tile Roll Forming Machine is mainly used for rolling, forming, cutting, stacking, etc. of this material, and the production efficiency is very high. The equipment is not only easy to operate and maintain, but also can easily replace the mold, so it can produce ordinary color steel tiles and glazed tiles, as well as high-strength load-bearing materials. The demand for this equipment is increasing year by year, so it has a good development prospect.

Features

1. Glazed Tile Roll Forming Machine is a highly automated forming machine, and can automatically determine the length of the finished product according to the length set by the operator, thereby improving production efficiency.

2. The device is made of high-quality steel, the overall strength is very high, and it is not easy to rust. After a long time of use, the device will not be easily deformed.

3. The reliable lubrication system can automatically lubricate bearings, moving guide rails, and other parts when the machine is running.

4. The combination of PLC control system, liquid crystal display, fault self-diagnosis system and error correction function makes the operation more convenient and safe.

Details

1. Main Motor Power: 5.5KW

2. Cycloidal Pinwheel Reduction Box: BWD27-43-5.5KW

3. Drive Sprocket: Pitch of 25.4mm

4. Rack: I-beam welding adopted and destressing

5. Unit Dimensions: 9m long, 1.7m wide and 1.4m high

6. Production Speed: 0-102m/min

7. Axle Diameter: 80mm and thermal refining

8. Bulging Axle Diameter: 80 mm and thermal refining

9. Bulging Roll Material: 45# Steel

10. Heat Treatment of Bulging Roll: 45# Steel electroplating

11. Number of Forming Stations: ≥14

12. Forming Shear Blade Material: 45# Steel

13. Heat Treatment of Sharing Blade: HRC58°C-62°C

14. Rolling Thickness: 0.4-0.6mm

15. Rolling Material: 45# Steel

16. The single surface of Cr electroplating rollers: 0.05mm

17. The product dimensions is up to the PRC's standard for Construction Product: GB/T12755-91

18. Scale Accuracy: 10m±2mm

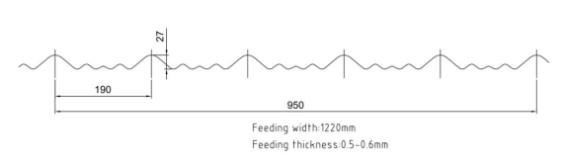

Drawing

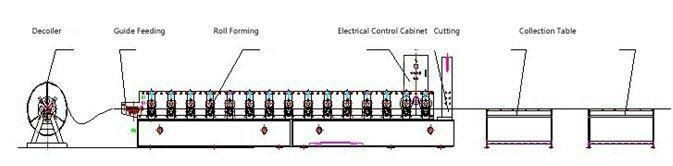

Technical Process

1220mm Coil → Guided Feeding → Roller Molding → Cutting to Length → Collection Table

Why choose us?

- We offer a wide range of metal roll forming machines to suit various industries.

- In the future, our company will continue to adhere to the business philosophy of professional construction and standardized management, regard product quality as its life, and actively research and develop new products. And to cooperate extensively with friends from all walks of life with a sincere attitude, mutual benefit and make greater contributions to the promotion of traditional culture and the development of Glazed Tile Roll Forming Machine career.

- We offer a wide range of metal roll forming machines to meet various manufacturing needs.

- Each of our Glazed Tile Roll Forming Machine is the bearer of high quality raw materials, experience and creativity.

- We offer quick and efficient delivery of our products to reduce downtime and increase productivity.

- Our mission is to create excellent Glazed Tile Roll Forming Machine for our customers. We have always adhered to the operation tenet of "efficient, professional and dedicated", adhering to the original intention of "continuous improvement, only to serve more customers", and won the recognition and trust of our customers with exquisite craftsmanship, excellent quality, and considerate service.

- We specialize in producing Metal Roll Forming Machines of the highest quality.

- We are bold in change, brave in pioneering, good at taking the initiative to find opportunities in various environments and conditions, grasp opportunities, and strive for development.

- Our machines are designed to optimize performance and reduce waste.

- The company took the lead in passing the three system certifications of quality management, environmental management, occupational health and safety management in the same industry, and obtained the national certification of intellectual property management system of the State Intellectual Property Office.

Hot Tags: glazed tile roll forming machine, Glazed Tile Roll Forming Machine, Steel Silo Rollformer, Beam Purlin Roll Forming Machine, Racking Shelf Roll Forming Machine, Steel Roll Forming Machine, Corrugated Forming Machine