Racking Omega Upright Column Roll Forming Machine

Description

Introducing the Racking Omega Upright Column Roll Forming Machine

The Racking Omega Upright Column Roll Forming Machine is an advanced and high-speed production machine that is specially designed for manufacturing racking omega upright columns. This machine is manufactured in China and is produced by one of the leading manufacturers of industrial machinery in the country.

The Racking Omega Upright Column Roll Forming Machine is designed for high precision and efficiency, which are critical features in the production of racking systems. The machine can produce up to 15 meters per minute with high accuracy, making it one of the fastest and most efficient machines in the market.

The machine is equipped with a robust frame structure that provides stability and durability even under high-speed and intense production environments. The frame structure is made of high-quality steel and features a hydraulic system that enables the machine to operate at maximum efficiency and accuracy.

The Racking Omega Upright Column Roll Forming Machine uses advanced technology to produce racking upright columns that are of high quality and standard. The machine is engineered to ensure that the produced columns are consistent in size, shape, and quality, ensuring that the final product meets the required specifications.

The machine features an easy-to-use touch screen control system that allows the operator to control and set the production parameters with ease. The control system features a user-friendly interface that makes it easy to adjust the production speed, length, and other critical factors that affect the production process.

The Racking Omega Upright Column Roll Forming Machine also features a quick changeover system that enables the operator to change the machine settings and specifications quickly. This feature is vital for industries that produce different sizes and shapes of racking systems, as it reduces downtime and increases productivity.

The Racking Omega Upright Column Roll Forming Machine is also very efficient and economical to operate. The machine is designed to consume low energy and maintenance costs, even in high-production environments. This feature makes it ideal for both small and large-scale production industries.

The Racking Omega Upright Column Roll Forming Machine comes with a warranty and after-sales support, ensuring that the customer gets value for money. The manufacturer offers training to ensure that the customers are familiar with the machine's operation, maintenance, and repair.

In conclusion, the Racking Omega Upright Column Roll Forming Machine is a high-speed, efficient, and reliable machine that is ideal for producing racking systems. The machine is designed to provide long-lasting operation and high-quality products that meet customer requirements. With its advanced technology, ease of use, and efficiency, the Racking Omega Upright Column Roll Forming Machine is the perfect solution for industries looking to enhance their production process while reducing downtime and increasing productivity.

Introduction

The power of the Racking Omega Upright Column Roll Forming Machine is strong, so it can work for a long time continuously, which greatly improves the production efficiency. The products produced by this machine have the advantages of high hardness, durability, waterproof, etc. The surface of this machine has been polished and polished, so it has good rust resistance. The machine is manufactured by rolling forming technology, so it has high precision and no surface defects. The machine adopts a high-end touch screen control system, so that the operator can better understand various parameters and production conditions.

Features

1. Racking Omega Upright Column Roll Forming Machine is fully automatic control, stable and convenient operation.

2. The machine is equipped with an emergency stop switch to quickly shut down the machine in case of emergency.

3. It is made of high-quality steel, so it can resist corrosion and rust.

4. We have a perfect distribution system and relatively stable logistics partners, so the distribution speed is very fast.

Parameters

* Material: G.i Coil

*Material Thickness:0.4-0.6mm

* Cutting system: Hydraulic servo tracking fast speed cutting;

* Main Power: 5.5KW

* Hydraulic power: 4kw+4kw

* Servo motor power: 1.5KW+1.5kw

* Forming Station: about 12 steps +12 steps( adopt Italy Technology )

* Axis Diameter: ¢ 50 mm

*Material of rollers: Cr12.

* Forming Speed: 10-45m/min

* Forming Frame Structure: Guiding Column + Slide Blocks; This forming frame structure design is much high precise than wall plate welding structure

* PLC Brand: DELTA Brand

* Machine Diameter: about 5500mm(L)x1000mm(W)x1500mm(H)

* Weight of machine: about 4 Ton

* Voltage: 380V, 3 Phase 50Hz ( or depend on customer’s requirement )

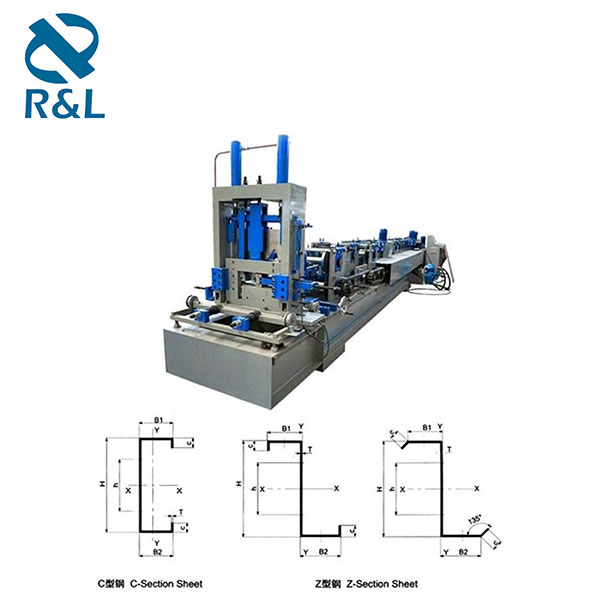

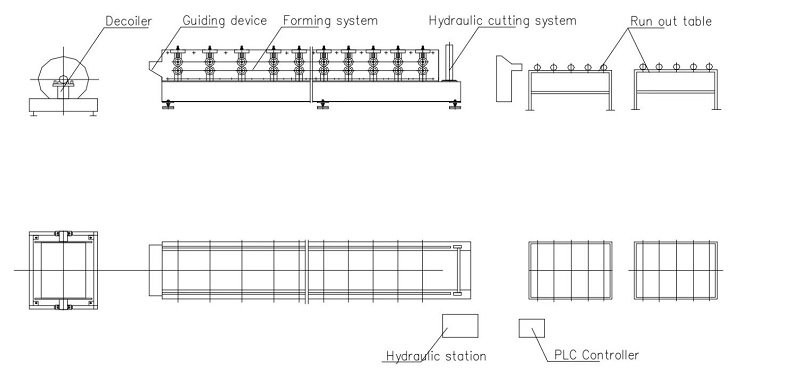

Working Flow

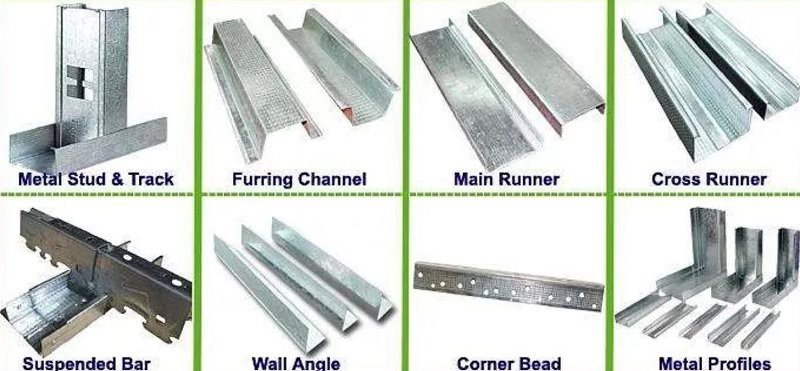

Finished profiles

Why choose us?

- We take pride in delivering the best quality metal roll forming machines to customers globally.

- We have the comprehensive advantages of talent, technology and management, and we wholeheartedly provide users with the whole process of quality service.

- We strive to provide the best service and products at the most competitive prices.

- In order to better respond to overseas markets, we have expanded the design team so that our Racking Omega Upright Column Roll Forming Machine will be suitable for more customers.

- Our machines are manufactured using the latest technology and advanced techniques.

- We always adhere to the principle of 'honesty and pragmatism, mutual benefit and win-win', and try our best to provide customers with all-round services. We sincerely look forward to your inquiry with full enthusiasm and rigorous attitude.

- Our metal roll forming machines are designed to be highly productive and cost-effective.

- Based on the needs of customers for products, the company adheres to the direction of industrial development, implements a large and refined brand development strategy, and is a dedicated and professional industry leader. We continue to research and innovate and provide customers with the best products with mature technology, rich experience, perfect service, and reasonable price.

- We have a stringent quality control process to ensure our machines meet the highest standards.

- We regard product quality as the cornerstone of winning the trust of customers, pursue better product quality and constantly innovate.

Hot Tags: racking omega upright column roll forming machine, Cable Tray Roll Forming Machine, Beam Purlin Roll Forming Machine, Metal Sheet Making Machine, Glazed Tile Roof Sheet Roll Forming Machine, Purlin Roll Former, Corrugated Forming Machine