Automatic Adjustable Cable Tray Machine

Description

to promote my product.

Introducing Automatic Adjustable Cable Tray Machine – The Revolutionary Solution for Cable Management

Cables are an indispensable component of modern infrastructure, connecting devices, and transmitting information across networks. As technology advances and the demand for faster and more reliable connectivity grows, the need for effective cable management becomes more critical. A poorly managed cable system can lead to disorganized cables, lost productivity, and even safety hazards. This is where the Automatic Adjustable Cable Tray Machine comes in, providing a comprehensive solution for cable management that is fast, flexible, and intelligent.

The Automatic Adjustable Cable Tray Machine is an innovative cable management solution that uses cutting-edge technology to produce high-quality, customizable cable trays quickly and efficiently. The machine is designed to streamline the cable management process, from design to production, and to deliver consistent, high-quality results that meet the diverse needs of customers.

The machine comes with numerous features that make it stand out among other cable tray manufacturing machines in the market. These include:

1. Automated Production Process: The machine is equipped with advanced automation technology that eliminates the need for manual labor and reduces the risk of production errors. This ensures that the quality of the products is consistent and that the manufacturing process is cost-effective.

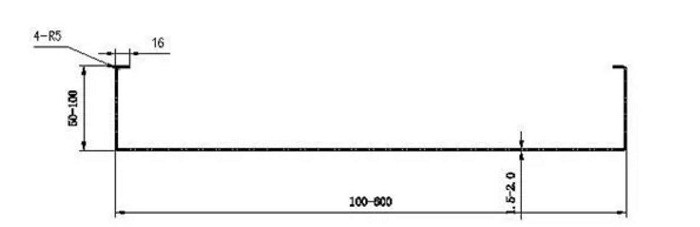

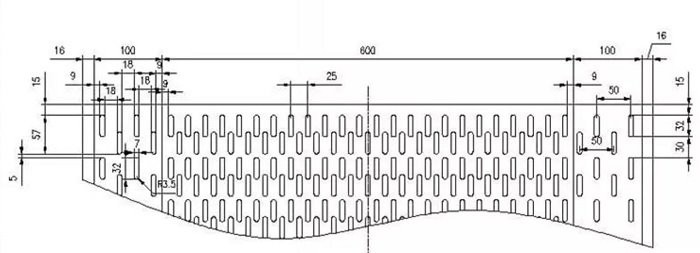

2. Customizable Design: The machine has a user-friendly interface that allows users to choose from a range of designs and customize their cable trays according to their specific needs. This includes adjusting the width, height, and depth of the trays, as well as the material used.

3. Fast Production Speed: The machine is capable of producing up to 150 meters of cable trays per minute, which significantly reduces lead times and benefits businesses through quicker project completion cycles.

4. High-Quality Output: The Automatic Adjustable Cable Tray Machine produces high-quality cable management products that are built to withstand the most challenging environmental conditions.

5. Energy Saving: The machine comes with a range of energy-saving features that reduce energy costs.

The Automatic Adjustable Cable Tray Machine offers numerous benefits to businesses that deal with cable management. These benefits include:

- Improved Efficiency: With the automated production process, businesses can reduce the amount of time and labor needed to manufacture cable trays, leading to improved efficiency and higher productivity.

- Customizable Design: The Adjustable Cable Tray Machine allows businesses to customize their cable tray designs, enabling them to meet the unique requirements of their projects.

- Cost-Effective Production: By eliminating the need for manual labor, the machine can reduce the cost of cable tray production, allowing businesses to offer their products at competitive prices.

- Quality Management: The machine's automated process ensures that products meet the highest quality standards without the risk of human error, which is critical to the reliability of the final product.

- Environmental Friendly: The Automatic Adjustable Cable Tray Machine comes with a range of energy-saving features that minimize energy consumption, making it environmentally friendly.

Conclusion

The Automatic Adjustable Cable Tray Machine is the future of cable management technology, offering businesses a range of benefits that are impossible to achieve with traditional cable tray manufacturing methods. With the machine's automated production process, customizable design options, and exceptional quality management capabilities, businesses can streamline their manufacturing process, reduce costs, and offer high-quality, reliable cable management solutions to their customers. As a manufacturer, our company is committed to providing our clients with the best quality of products to help them optimize their cable management needs - all while improving their overall efficiency and operations.

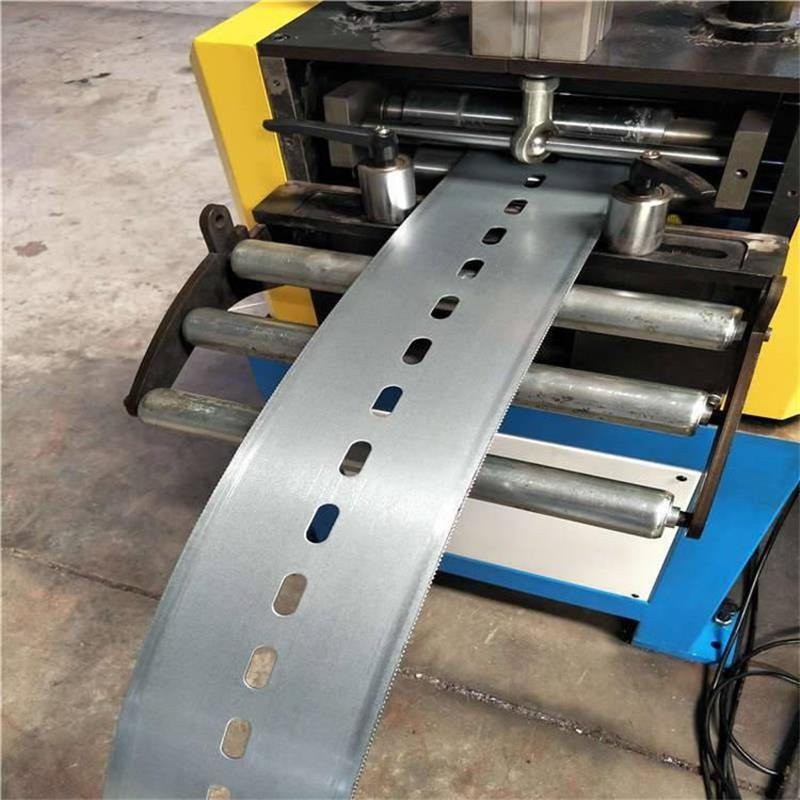

Introduction

This Automatic Adjustable Cable Tray Machine is used to make insulated cables related to power distribution and communication. The machine body is finished as a whole, so the flatness is high and the profile forming error is smaller. The machine adopts programmable PLC control system and frequency converter speed regulation, so the operation is simple and user-friendly. One machine can complete punching, cutting and other requirements, and we can also customize according to your needs. If you have any questions, you can also consult us at any time.

Features

1. The Automatic Adjustable Cable Tray Machine runs stably and has high productivity, and can execute production orders more efficiently and accurately;

2. The machine consumes less materials and energy than ordinary machines;

3. It is made of high-quality materials, so its service life is longer;

4. All parts of the machine have been precision processed, such as chrome plating on the surface, which prevents the surface paint from being scratched and improves the service life of the roll;

5. We provide various solutions to solve various technical problems.

Automatic inner tight decoiler | 1. coil inner diameter 450mm-550mm |

| 2. maximum width of coiling 600mm | |

| 3. maximum weight of loading 2500kg | |

Main forming machine | 1. Forming stations: 11rows |

| 2. material of shaft: 45# steel. Outer diameter 60mm | |

| 3. main motor power: 5.5kw | |

| 4. The speed of forming: 0-50m/min | |

Hydraulic cutter | 1. material of blade: Cr12 mould steel with quenched treatment 60-62 |

| 2. cutting system: adopt advanced hydraulic drive, after forming automatic cut, no distort, no wasting, high safety factor. (tracking cutting) | |

The electrical control system | 1. The Brand of display: DELTA |

| 2. The main computer (PLC): DELTA DVP14 |

Why choose us?

- We are committed to ensuring our customers are satisfied with our products and services.

- Our company adheres to the business philosophy of "customer-oriented, based on low price and high quality, with customer satisfaction as the goal".

- We are committed to providing environmentally-friendly solutions for our customers.

- 'Aggressive Price, Fast Service' for Automatic Adjustable Cable Tray Machine.

- Our products are built to last and withstand rigorous use.

- Our company's management culture is a key belief that we have believed in for our long-term development, and is the foundation of the culture we have inherited and carried forward.

- We have a reliable and efficient supply chain, ensuring timely delivery of our products.

- We pursue the continuous development of technology, constantly create core technology and cultivate high precision talents, maintain the leading position of technology in the industry, and make new progress every day.

- Our machines are customizable to meet specific requirements, delivering tailored solutions to our customers.

- We continue to innovate technology around enhancing customer value.

Hot Tags: automatic adjustable cable tray machine, Chinese Roll Forming Machine, Cold Roll Forming Machine, Multi Rib Span Roof Sheet Roll Forming Machine, C Section Rollformer, Steel Roof Ridge Cap Roll Forming Machine, Double Layer Roll Former