Roll Forming Metal Roofing Machines

Description

Introducing Roll Forming Metal Roofing Machines – The Future of Roofing

Our Roll Forming Metal Roofing Machines are the ultimate solution for roofing businesses looking to improve their efficiency and quality of products. Our machines are designed to automate the process of manufacturing metal roofing, making it easier and faster than ever before.

At our factory in China, we use the latest technology and equipment to manufacture these professional-grade machines. We have a team of skilled engineers and technicians who design and build our machines to the highest standards of quality and durability.

Our Roll Forming Metal Roofing Machines are known for their precision, accuracy, and ease of use. They are designed to produce consistent, high-quality metal roofing quickly and efficiently, which is valuable for any business looking to improve its productivity and profitability.

Key Features and Benefits of Roll Forming Metal Roofing Machines:

1. High production capacity

Our Roll Forming Metal Roofing Machines are designed to produce a high volume of metal roofing quickly and efficiently. This means that businesses can produce more products in less time, which translates to increased revenue and profits.

2. Versatile

Our machines are versatile and can be used to produce various types of metal roofing, including corrugated, standing seam, and tile profile. This means that businesses can cater to a diverse range of customers and projects.

3. Easy to use

Our machines are designed to be user-friendly, even for those without prior experience in metal roofing manufacturing. They are intuitive and easy to operate, which reduces the risk of errors and increases productivity.

4. Precision and accuracy

Our machines are engineered to the highest level of precision and accuracy. This means that the final products are of consistent quality, which is essential for customer satisfaction.

5. Low maintenance

Our machines are built to last, and we only use high-quality materials and components, reducing the need for repairs and maintenance. This minimizes downtime and increases productivity.

6. Cost-effective

Our machines are an investment in the future of your business. They are designed to last for years and require minimal maintenance, which makes them a cost-effective solution for any roofing business looking to improve their manufacturing process.

Why choose us?

1. Quality Control

We understand that our customers rely on us to deliver high-quality products and services. Therefore, we have implemented strict quality control measures to ensure that our machines meet the highest standards of quality.

2. Competitive Pricing

Our Roll Forming Metal Roofing Machines are competitively priced to ensure that our customers get the best value for their money.

3. Experienced Team

We have a team of experienced professionals who are dedicated to providing our customers with excellent service and support.

4. After-Sales Service

After-sales service is crucial when investing in new machinery. We offer comprehensive after-sales support to our customers to ensure that their machines are operating at peak efficiency.

In conclusion, our Roll Forming Metal Roofing Machines are an excellent investment for roofing businesses looking to improve their manufacturing process. With their high production capacity, versatility, ease of use, precision, accuracy, low maintenance, and cost-effectiveness, our machines are poised to become the future of roofing. Choose us for the best quality machines at the most competitive prices.

Introduction:

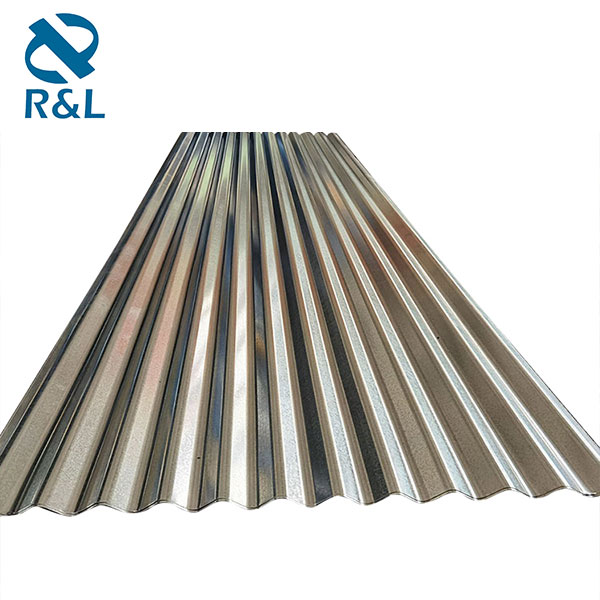

The Roll Forming Metal Roofing Machines are specially designed for roll forming of color steel corrugated roofing and wall panels. And it has good hardness and flexibility, and can be widely used in villages, hotels, exhibitions, resorts, home construction, outdoor decoration, etc. Secondly, our products are produced by roll forming metal roofing machines. The surface is very smooth and beautiful without any scratches on the surface. What's more, our adjustable sheet width pre-cutting knife, when the machine finishes a roll of heavy steel plate, it is easy to cut the sheet. Finally, our products can be custom produced, and we can design machines according to your specifications and outline drawings.

Feature

The parts of Roll Forming Metal Roofing Machines are precision-machined, and the surface of the roller is chrome-plated, which not only ensures that customers get qualified products, but also avoids scratches on the surface of the color steel and increases the service life. Secondly, the equipment of our products in the grinding system can make full use of the production capacity of the grinding equipment. Generally, the output can be increased by 30%-40%, and the total energy consumption can be reduced by 20%-30%. More importantly, our products have the characteristics of simple structure, small space occupation, and convenient operation and maintenance. Finally, it also has the characteristics of less dust and low noise, and the working environment has been greatly improved.

Process Drawings:

Forming section

|

Adjustable center of the forming rollers and of sufficient length to prevent lateral movement of the strip on its entry to flattener.

|

Cutting :

|

Cutting after forming: Cut the sheet after roll forming to required length.

Length measuring: Automatic encoder length measuring, Brand: Omron

|

|

Collection Table

|

Jointed by 60mm*40mm tube Two sets

|

Hydraulic station:

|

Hydraulic power: 4kW

|

|

PLC control

|

1)Programmable setting of profile length and quantity 3)Operating system language: English and Chinese

4)Computer used to control length & quantity. The machine will automatically cut to length and stop when the required quantity is achieved

|

Why choose us?

- We offer a wide range of metal roll forming machines to meet various manufacturing needs.

- We offer wonderful energy in high-quality and improvement, merchandising, product sales and marketing and advertising and procedure for Roll Forming Metal Roofing Machines.

- Our metal roll forming machines are durable and reliable, ensuring long-term stability and cost-effectiveness.

- The company has a professional team with many years of technical experience, adhering to the spirit of "being meticulous and striving for perfection" to create practical and practical process solutions and equipment for customers and friends.

- We have a reliable and efficient supply chain, ensuring timely delivery of our products.

- We can provide a complete set of solutions and comprehensive services according to the actual situation of domestic and foreign customers. Let customers rest assured, satisfied and guaranteed is our eternal goal.

- We provide ongoing support to ensure our machines operate at peak efficiency.

- It is our adherence to the scientific concept of development, concerted efforts, hard work and unity that have brought us to our present achievements.

- Our team of experts has extensive experience in the manufacturing of Metal Roll Forming Machines.

- Our mission is to create value for our customers, make our employees grow and live better, and contribute to the progress of society.

Hot Tags: roll forming metal roofing machines, Steel Corrugated Sheet Roll Forming Machine, Standing Seam Roll Forming Machine, Sheet Roll Forming, Double Layer Roll Forming Machine, Highway Guardrail Machine, Beam Purlin Roll Forming Machine