Roller Shutter Door Forming Machine

Description

Welcome to our product introduction for the Roller Shutter Door Forming Machine! Our machine is a state-of-the-art manufacturing system designed to create high-quality roller shutter doors quickly and efficiently. It is widely used by merchants and manufacturers around the world for its reliability, precision and ease of operation.

If you are looking for a reliable and efficient machine that can revolutionize your manufacturing process, then the Roller Shutter Door Forming Machine is the perfect solution. With its advanced technology and design, this machine is guaranteed to deliver excellent results every time. Here are some of the key features that make this machine stand out:

1. High-Quality Manufacturing: Our Roller Shutter Door Forming Machine is built to produce high-quality roller shutter doors that meet the strictest industry standards. With its precise cutting and shaping capabilities, this machine can create doors that are strong, durable and visually appealing.

2. Speed and Efficiency: Our machine is designed for speed and efficiency, with the ability to produce up to 20-30 sets of roller shutters per day. This level of productivity means that our machine can help you to meet your production targets and increase your profitability.

3. Easy to Use: Our Roller Shutter Door Forming Machine is incredibly easy to use, even for those who are new to the manufacturing process. Our user-friendly design and easy-to-follow instructions make it simple for operators to get started quickly and efficiently.

4. Low Maintenance: Our machine is designed for low maintenance, with minimal wear and tear on parts. This means that you won't need to spend a lot of time and money on repairs and replacements, helping you to save money and reduce downtime.

5. Customizable: At our company, we understand that every merchant has unique needs and requirements. That's why we offer fully customizable Roller Shutter Door Forming Machines that can be tailored to your specific manufacturing needs.

6. Competitive Pricing: Despite its advanced features and capabilities, our Roller Shutter Door Forming Machine is competitively priced within the market. We strive to offer affordable solutions that can help you to increase your productivity and profitability.

In addition to these key features, we are dedicated to providing exceptional customer service and support. We offer technical assistance, training and maintenance services to ensure that you get the most out of our Roller Shutter Door Forming Machine.

In conclusion, the Roller Shutter Door Forming Machine is a must-have for any merchant looking to increase their production capacity and efficiency. With its advanced features, reliability and ease of use, it is the perfect solution for manufacturing high-quality roller shutter doors that meet the strictest industry standards. Contact us today to learn more about how our machine can revolutionize your production process and increase your profitability.

Introduction:

The Roller Shutter Door Forming Machine is mainly composed of feeding platform, forming machine, forming and shearing device, hydraulic station, computer control system and other parts, and are used in conjunction with the sewing machine. Secondly, each part of the machine is precisely processed, and the surface of our roller is chrome-plated, which can ensure that customers can get qualified products, and at the same time, it can avoid scratches on the surface paint of the color steel and increase the service life of the roll. More importantly, we use high-quality materials to make it, which has the characteristics of longer service life. Finally, our products are mainly used in the production of rolling shutters suitable for garages, workshops, warehouses and other places.

Feature

The Roller Shutter Door Forming Machine is a versatile and efficient tool for manufacturing high-quality rolling doors. It has the characteristics of simple operation, fast production speed and strong durability. In addition, the machine is capable of customizing the size and shape of doors to meet specific needs. Overall, our products are an excellent investment for door manufacturing.

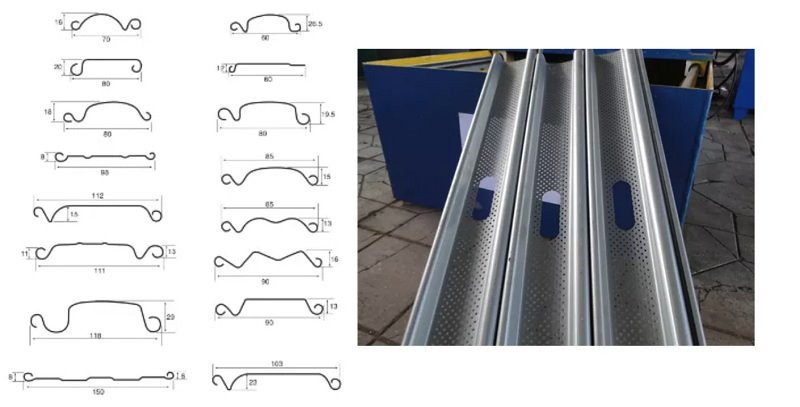

Drawing

Working flow

De-coiler—→level device—→main roll forming machine—→ hydraulic cutting—→ run-out table

Machine component

3T-5T Passive De-coiler

Diameter: 460-520mm expansion.

Expansion: Manually

Capacity: 3000kg

Leveling device

1.7 rolls leveling, 3 rolls up, and 4 rolls down

2. Diameter is Ø 70mm, chrome and HRC60 heat treatment to secure the smooth surface

3. Max Leveling Raw Material width: 300mm

Hydraulic station

1. hydraulic station pressure: 12MP

2. power of hydraulic station: 4KW

Hydraulic Cutting

1. The cutter blade material: Cr12mov HRC58-62 degree

2. Blades number: 2 sets

3. Cutting after forming: Cut the sheet after roll forming to the required length

4. Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start.

5. Material of blade: CR12with heat treatment

6. Length measuring: Automatic length measuring

7. Tolerance of length: 6m+/- 0.5mm

Control Box

(1) Power supply: 380 V, 50 Hz, 3Phase (adjusted with the requirement)

(2) Length & quantity measurement automatically;

(3) Length & quantity controlled by PLC,

(4) Length inaccuracy can be amended easily.

(5) Control panel: Button-type switch and touch screen

(6) Unit of length: millimeter (switched on the control panel)

Output Table

Length: 2m

Quantity: 2 units

Why choose us?

- We provide ongoing support to ensure our machines operate at peak efficiency.

- The scale and grade of the enterprise have been constantly improved, which can produce Roller Shutter Door Forming Machine with complete varieties and excellent performance for the majority of users and provide first-class professional services.

- We strive to provide the best service and products at the most competitive prices.

- With the enterprise spirit of "honesty and efficiency, hard work, pioneering, and the pursuit of excellence", we have achieved the extraordinary and leap-forward development of our company scale and brand.

- We provide excellent after-sales service to ensure customer satisfaction.

- We are committed to creating reliable products and improving service quality for customers, and strive to become a leading manufacturer for Roller Shutter Door Forming Machine in the industry.

- Our machines are versatile and can be used to produce a wide range of products.

- Our company attaches importance to the high degree of unity between intellectual property strategy and business development, science and technology innovation to meet the needs of business operation and market.

- We offer quick and efficient delivery of our products to reduce downtime and increase productivity.

- We take professional technology as the core and star-level service as the guide, and strive to provide customers with perfect products and high-quality services to create value for customers.

Hot Tags: roller shutter door forming machine, Shutter Door Forming Machine, Roof Sheet Roll Forming Machine, Z Purlin Forming Machine, Cold Roll Forming Machinery, Closed Type Floor Decking Roll Forming Machine, Decking Floor Roll Forming Machine