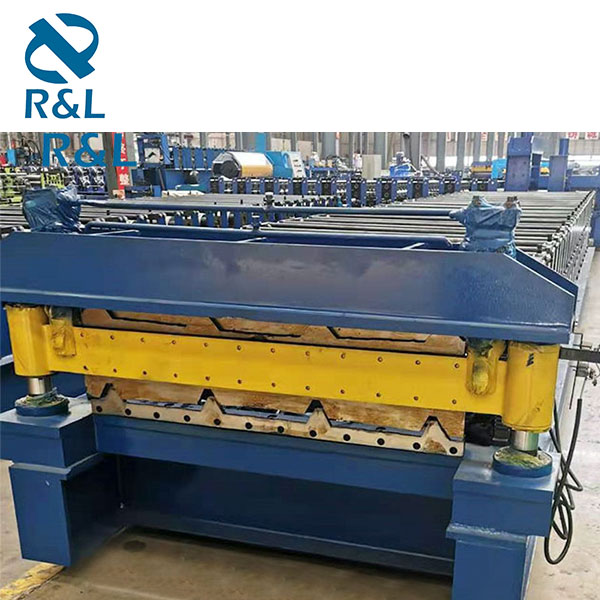

Roof And Wall Panel Roll Forming Machine

Description

Roof And Wall Panel Roll Forming Machine: The Ultimate Solution for Efficient Panel Production

As a manufacturer, we understand the importance of having a reliable and efficient solution for panel production. This is why we are proud to introduce our Roof and Wall Panel Roll Forming Machine – a revolutionary solution that promises to simplify and streamline the panel production process.

With years of experience in the industry, we have developed a machine that is not only easy to operate but also delivers quality results every time. Our Roof and Wall Panel Roll Forming Machine is designed to provide a wide range of features that meet the needs of both novice and seasoned panel producers.

Features and Benefits:

Highly Efficient Production Capabilities

Our Roof and Wall Panel Roll Forming Machine comes with a powerful and versatile motor that is capable of sustained, high-speed production runs. This motor ensures that you will have an uninterrupted workflow that allows you to produce more panels in less time, ultimately increasing your overall output.

Easy Operation and Maintenance

One of the standout features of our machine is its user-friendliness. It is designed to be easy to operate and maintain, making it a great option for those who are new to panel manufacturing. Additionally, our machine is built for durability, with easy-to-replace parts, ensuring that you can enjoy hassle-free production runs for years to come.

Versatile Application

Our Roof and Wall Panel Roll Forming Machine is versatile enough to handle a wide range of panel types, making it an ideal solution for any panel producer. Whether you need to produce roofing panels or wall panels, our machine is fully equipped to handle any task.

High-Quality Production Results

At our core, we believe in delivering the highest possible quality to our customers. Our Roof and Wall Panel Roll Forming Machine is designed with precision engineering, ensuring that every panel produced meets the highest quality standards.

Cost-Effective Solution

We understand that cost is often a major concern for merchants, which is why we have made our Roof and Wall Panel Roll Forming Machine a cost-effective solution that provides maximum value for your investment.

Final Thoughts:

In summary, our Roof and Wall Panel Roll Forming Machine is a top-of-the-line solution for efficient panel production. With its high-speed production capabilities, easy operation and maintenance, versatile application, and high-quality production results, it is the ultimate solution for panel production. Whether you are a novice or seasoned panel producer, our machine is sure to deliver the results you need – all while keeping your costs low. We are confident that you will be satisfied with this innovative solution, and we look forward to partnering with merchants in countries outside of China to bring our machine to you.

Introduction:

The Roof And Wall Panel Roll Forming Machine is a kind of equipment for processing metal sheets. By rolling metal sheets along a certain bending curve, various shapes of wall panels and roofs can be made. Secondly, our products have a certain degree of automation and production efficiency, can meet the needs of mass production, and are widely used in construction, machinery, automobiles, and other industries. More importantly, our products are simple and convenient to operate. It can be controlled manually and automatically. Different molds can also be configured to achieve different shapes of wall panels and roof processing. Finally, our products have a good quality assurance.

Feature

The input performance of Roof And Wall Panel Roll Forming Machine is excellent, and the AB phase has strong anti-interference ability. And use the fixed value interrupt function to ensure the accuracy. Secondly, the executive part of the machine has a variable frequency drive motor, a hydraulic station motor, two press-fit hydraulic solenoid valves, and two cutter hydraulic solenoid valves. More importantly, we cooperate with KDN text screen to complete parameter setting, alarm display, help information, production data display, etc. Finally, the PLC of our product has 14 inputs/10 relay outputs, which just meets the input and output requirements.

Machine Specifications:

|

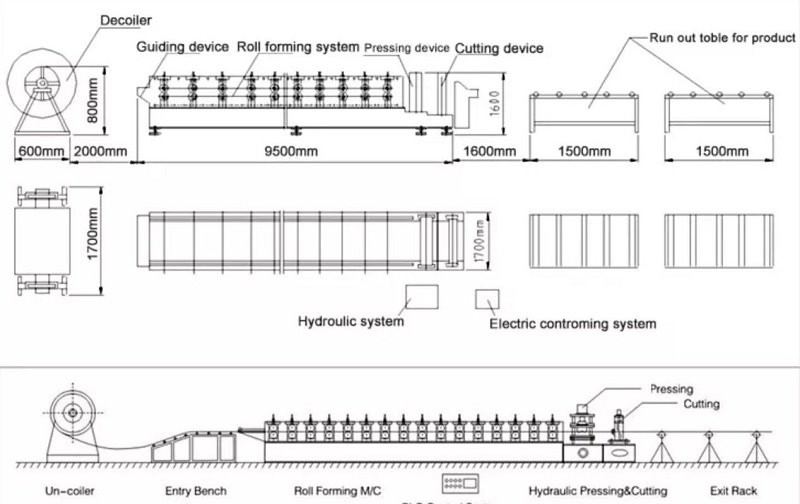

Manual Decoiler |

Usage: Mainly used to support steel coils, and manually uncoil and straighten the coil into the feeding table. Steel coil width: 940, 1200, 1220 mm. (According to your actual drawing) Loading capacity: 5T Inner diameter: 500-508mm

|

|

Guiding Device |

Adopt a guiding bar and sliding block to control the width and position of the steel sheet. |

|

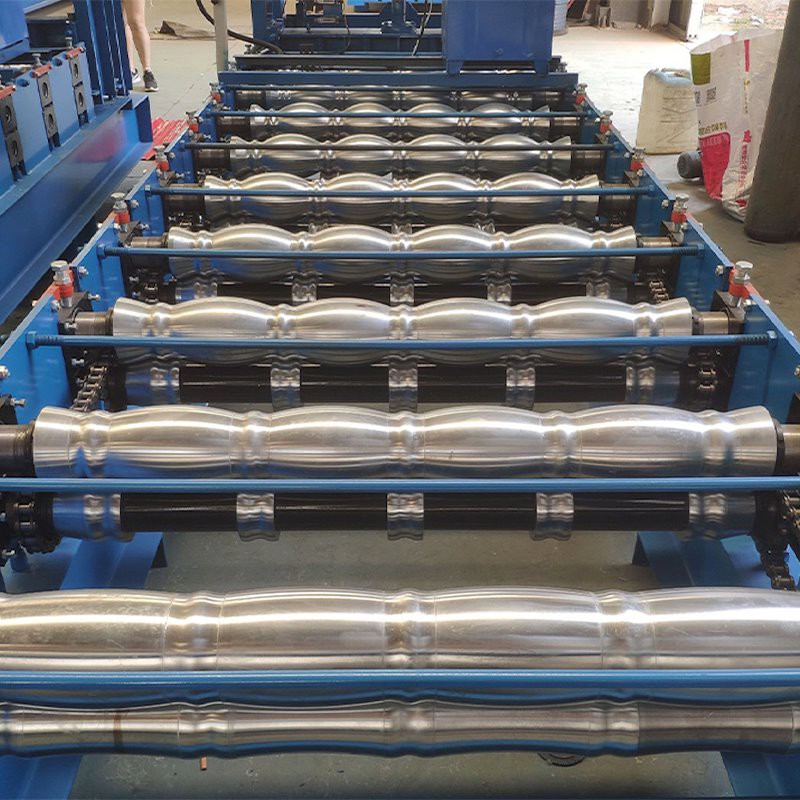

Roll Forming System |

Material of rollers: High grade 45# steel, roller surfaces polishing, hard plating chrome coated 0.05mm The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped. |

|

Cutting device |

A. Adopts post cutting, the cutting blade material is Cr12 with quenched treatment, after cutting, there is no material wasted. |

|

Hydraulic System |

It is controlled by a gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drives the cutter machine to begin the cutting job. |

|

PLC Control System |

The target piece`s length is adjustable and the digit of it can be adjusted. Computed mode has two modes: automatic and manual. The system is easy to operate and use |

|

Run out table |

To receive the finished products. |

2. Process Drawing

FAQ:

1. Q: What payment terms do you accept?

A: T/T or L/C or West Union or Moneygram or Paypal.

2. Q: Will you arrange the installation of the machine at present after we place the order?

A: All machines will be well tested before delivery, so almost all machines can be used directly, and our machines are easy to install, if your customers need our help, we are happy to arrange the installation, but all costs will be charged by you .

3. Q: How to get after-sales service?

A: If we cause problems, we will provide you with spare parts for free.

If it is man-made problem, we will also send spare parts, but it will be charged. Any questions, you can call us directly.

Why choose us?

- We offer a wide range of metal roll forming machines to suit various industries.

- We have designed and developed satisfactory solutions for customers from dozens of different countries.

- We have a proven track record of delivering high-quality metal roll forming machines to customers worldwide.

- We introduce domestic and foreign advanced production equipment, production technology, strong technical force, and advanced management mode, and continue to innovate and improve our Roof And Wall Panel Roll Forming Machine.

- We provide expert advice and support to ensure our customers make informed decisions.

- We regard providing both material and spiritual happiness for our employees as well as providing a better and bigger development platform as our core values.

- Our machines are designed to reduce labor costs and increase efficiency.

- Our company constantly solves the subtle deficiencies in market development, Roof And Wall Panel Roll Forming Machine quality, scientific research and development and enterprise management, so as to occupy a larger market share.

- We have a reliable and efficient supply chain, ensuring timely delivery of our products.

- In the future, we will resolutely implement the new development concept and focus on the goal of creating a world-class enterprise.

Hot Tags: roof and wall panel roll forming machine, Rolling Shutter Roll Forming Machine, Glazed Tile Roof Sheet Roll Forming Machine, Shape Roll Forming Machine, Z Purlin Forming Machine, C Z U Shape Purlin Rollformer, CZ Purlin Roll Forming Machine