Roofing Sheet Roll Forming Machine

Description

Introduction:

Welcome to the world of roofing sheet roll forming machines, where we offer you the latest and most advanced technology in the market. As one of the leading manufacturers of roll forming machines in China, our company specializes in providing quality roofing sheet roll forming machines to global merchants. Our machines are engineered to produce high-quality roofing sheets that meet a diverse range of requirements, making them a popular choice for construction and manufacturing industries worldwide.

In this product introduction, we will cover the key features, benefits, and advantages of our roofing sheet roll forming machine. We will also provide insights into how our machine can help businesses achieve their manufacturing and production goals while improving efficiency and reducing costs.

Product Features:

Our roofing sheet roll forming machines are designed with the latest technology to ensure optimal performance and efficiency. We use high-grade materials like steel, aluminum, and other alloys to manufacture these machines, which makes them highly durable and long-lasting. Our machines are also equipped with PLC control systems, which allow for easy and accurate operation.

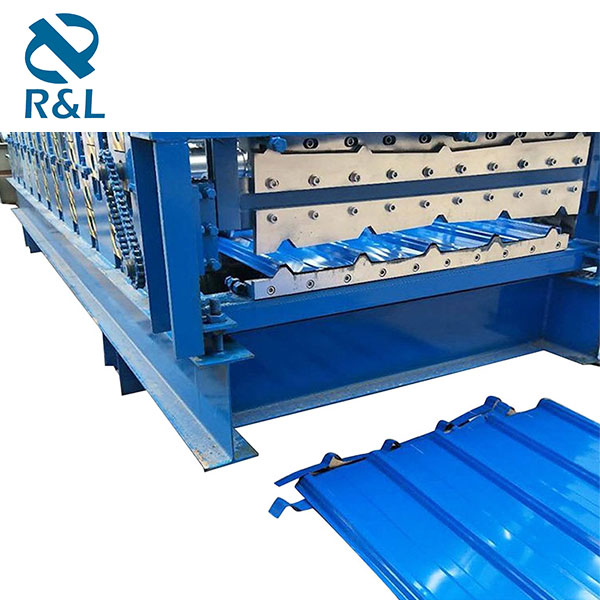

The machine consists of feeding, forming, and cutting sections. The feeding section accepts the raw material, which is then passed through the forming section to shape the material into the required roofing sheet profile. Lastly, the cutting section cuts the roofing sheets to the desired length. The whole process is automated and finished in a matter of minutes, reducing labor time and human error.

In addition to the standard features, our roofing sheet roll forming machines also have customization options. Specifically, we can adjust the size, shape and profile of the roofing sheets to customers' specifications. Customization services offer greater flexibility to produce roofing sheets that meet specific project requirements.

Benefits and Advantages:

Our roofing sheet roll forming machines come with several benefits and advantages that make them the preferred choice for many merchants around the world. The benefits include:

1. High Quality Roofing Sheets: Our machines are designed to produce high-quality roofing sheets that meet industry standards. We use the best raw materials and advanced manufacturing processes to ensure our roofing sheets are durable and can withstand extreme weather conditions.

2. Reduced Labor Time and Cost: Our machines require little human input and are fully automated, which reduces labor time and cost. This translates to significant cost savings for businesses, lower overheads and higher profit margins.

3. Customizable Profiles: We offer customization options, allowing merchants to shape and produce roofing sheets of different profiles, sizes and shapes according to specific project requirements.

4. User-friendly: Our roofing sheet roll forming machines are user-friendly and easy to operate. We provide training and installation services to ensure our customers can operate the machine seamlessly.

5. Wide Applications: Our machines find wide use applications in construction industries including building sheds, warehouses, factories, and residential homes.

Conclusion:

Our roofing sheet roll forming machines offer merchants unmatched quality and affordability. They are ideal for businesses looking to increase efficiency, reduce labor costs, and produce high-quality roofing sheets that meet specific project requirements. Our machines are customizable to accommodate individual project requirements and we offer professional installation and training services. Order your roofing sheet roll forming machine today, and take the first step towards a successful construction business.

Introduction:

The Roofing Sheet Roll Forming Machine is a machine commonly used in the production of corrugated roof panels. It can process the steel plate through a series of processes and press it into a corrugated roof panel material. Secondly, our products can resist various natural disasters and harsh weather conditions, ensuring the smooth progress of industrial and agricultural production. More importantly, our products are very easy to install and use. Finally, if you are interested in our products, please contact us in time.

Feature

The steel belt used in Roofing Sheet Roll Forming Machine has excellent strength, compressive strength, and yield strength, and high-quality physical properties can ensure a balanced working pressure in all forming sections. Secondly, the steel strip is in direct contact with the surface of the green body, and the surface condition of its working table will affect the surface quality of the finished product material at the same time. More importantly, the steel belt is significantly better than the transmission belt in the fields of physical properties and surface flatness. The high-quality flatness can ensure the safe and reliable operation of the rolling machine, and the thickness of the pressed product is consistent. Finally, our products have a good quality assurance.

Main Specifications:

|

Raw Material |

Feeding with |

up layer 1000mm down layer 1000mm |

|

Effective width |

up layer 820 down layer 836 |

|

|

Thickness |

0.3-0.8mm | |

|

Main Forming Machine

|

Roller material |

45# steel plated with chrome |

|

Diameter of shaft |

70MM | |

|

Roller station |

16-18 | |

|

Main Configuration |

main motor power |

5.5kw |

|

hydraulic station power |

4kw | |

|

control system |

PLC (Mitsubishi) |

Composite:

|

Automatic Hydraulic Decoiler(Optional) Loading Capacity: Max 5000kg Suitable Coil Width: 1300mm Driving Motor Power: 3.0kw Pump Station Power: 3.0kw |

|

Feeding Frame Structure: Steel Plate Welded Function: Bearing Guiding Extra Function: Pre-cutting Pre-cutting Material: Cr12Mov |

|

Roll Forming Under Frame: 350H Beam Sidewall Thickness: 16mm Steel Plate Roller Station: 18 forming units Shaft Diameter: 70mm

|

|

Shaft Material: High grade 45# steel, heated and quenched cylindrical grinding. Roller Material: High grade 45# steel, heated and quenched, hard chrome coated 0.05mm

|

|

Hydraulic Cutting Working Method: Stop to post, and post to cut Guide Pillar: Long life Pump Motor Power: 3.0kw Cutting Blade: Cr12Mov |

Why choose us?

- We take pride in producing metal roll forming machines that are durable and reliable.

- Through years of hard work and struggle, our company adheres to the supremacy of credibility and considerate service, and is at the forefront of the market. In the future, we will also make creative contributions to the development and prosperity of the industry.

- We are committed to ensuring our customers are satisfied with our products and services.

- Adhering to quality-oriented, focusing on customer needs and continuous innovation, is our way of prosperity.

- Our machines perform at a high level, ensuring consistent and reliable results every time.

- We will get closer to the market, recognize market needs faster, and develop more personalized Roofing Sheet Roll Forming Machine and services.

- Our machines are easy to operate and maintain, reducing downtime and increasing productivity.

- With the development of global economy, as one of the important systems of company management, performance management has been paid attention to and applied by our company.

- We have a reliable and efficient supply chain, ensuring timely delivery of our products.

- In the operation and management, we always uphold the enterprise spirit of integrity and courage and the core values of integrity and harmony.

Hot Tags: roofing sheet roll forming machine, C Shape Purlin Roll Forming Machine, HIgh Speed Purlin Roll Forming Machine, Standing Seam Roll Forming Machine, Door Frame Roll Forming Machine, Self Lock Roof Panel Roll Forming Machine, Decking Floor Roll Forming Machine