Sheet Metal Roll Forming Machines

Description

Product Description

Sheet Metal Roll Forming Machines are designed to roll form metal coils into specific shapes and lengths. This machine is an automatic, easy-to-operate, and high-efficiency equipment for producing various metal profiles.

The machine is equipped with a precision-constructed rolling system that is capable of handling different types of materials, such as aluminum, stainless steel, and galvanized steel.

The Sheet Metal Roll Forming Machine works without any waste material or noise pollution, minimizing environmental impact and producing high-quality products.

Features and Advantages

There are many features and advantages that make Sheet Metal Roll Forming Machines stand out from the competition. Here are some of those features:

1. Durability: Sheet Metal Roll Forming Machines are made from high-quality materials, ensuring that they can handle the toughest jobs and last for many years.

2. Speed: The machines are fast and efficient, producing high-quality products in a short amount of time.

3. Accuracy: Sheet Metal Roll Forming Machines have a high degree of accuracy, producing consistent and precise results every time.

4. Flexibility: These machines can be used to produce a wide range of products, making them suitable for a variety of applications.

5. Safety: Sheet Metal Roll Forming Machines are equipped with safety features, ensuring that operators are safe while working with the equipment.

6. Easy to Use: These machines are easy to operate, even for those who are new to the industry.

Application

Sheet Metal Roll Forming Machines are versatile and can be used in a variety of applications. Here are some examples of industries where these machines are commonly used:

1. Construction: Sheet Metal Roll Forming Machines are used in the construction industry to produce metal roofing and wall panels.

2. Automotive: These machines are used in the automotive industry to produce parts such as fenders, bumpers, and doors.

3. Aerospace: Sheet Metal Roll Forming Machines are used in the aerospace industry to produce aircraft components.

4. Electrical: These machines are used in the electrical industry to produce wire and cable trays.

5. Furniture: Sheet Metal Roll Forming Machines are used in the furniture industry to produce metal furniture frames and legs.

Conclusion

Sheet Metal Roll Forming Machines are versatile, efficient, and effective pieces of equipment that are perfect for producing a wide range of metal profiles. They offer many advantages over traditional metal forming methods, including speed, accuracy, and flexibility.

If you're looking for a reliable and durable machine that can handle any job, then Sheet Metal Roll Forming Machines are the perfect choice. Contact us today to learn more about our machines and how they can benefit your business.

Introduction:

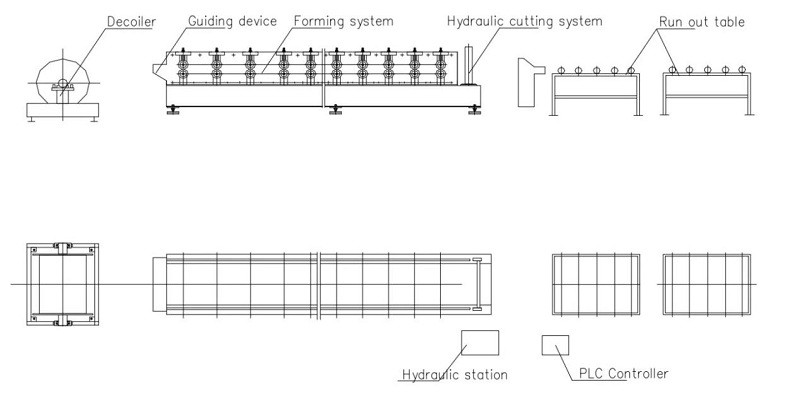

The Sheet Metal Roll Forming Machines press the metal sheet into the required shape and size through the rotation and extrusion of the roller. It is widely used in manufacturing, construction, furniture manufacturing and other fields, and can produce metal products of various shapes, such as roof panels, wall panels, doors and windows, guardrails, etc. Secondly, our products are often composed of multiple components, including feeder, rolling machine, shearing machine, etc. These components work together to complete the entire processing process. Finally, our products can also be customized and optimized according to different production needs. It is an efficient, precise and stable machine that can meet the production and customization needs of different industries.

Feature

The Sheet Metal Roll Forming Machines are characterized by high efficiency, precision and stability, which can greatly improve production efficiency and product quality. Secondly, our products roll different structural designs on the silk board onto the workpiece. Various threads, protruding rings, knurls, end chamfers, grooves with different depths and widths, and other desired shapes can be rolled out as required. More importantly, the use of our products can avoid scratches on the paint on the surface of the color steel and increase the service life. Finally, we have customized coil processing solutions to solve various technical problems.

Raw material | Galvanized steel or PPGI |

Thickness | 0.3-1mm |

Roller stations | 13 or depending on the customer' drawing |

Shaft diameter | 75mm |

Solid shaft material | High grade 45# steel with Cr12 mov coated, quenching & tempering & treatment |

Roller material hardness 30-40 HRC | Cr12 |

Machine size | About 6*1.5*1.3 m |

Production speed | 8-20 m/min |

Cutting tolerance | ± 1mm |

Cutter material | Cr12 |

Cutting operate | Hydraulic cutting |

Driving way | Chain 1 inch |

Main forming power | 4kw |

Power for cutter | 3kw |

Voltage | 380V/50HZ, 3P, or Customized as customer's request |

PLC brand | Delta made in Taiwan |

Screen | Touchable screen |

In order to serve you better, please contact us and provide the following basic information:

1. Required raw materials (aluminum or steel)

2. Required Height of wave(H)

3. Distance between two waves (D)

4. Width (W) required for finished product or film delivery

5. The length of the finished product and the thickness of the paper you need

We will recommend the corresponding machine according to the value you provide, serve you faster and more efficiently, and avoid unnecessary waste!

Why choose us?

- Our team of experts has extensive experience in the manufacturing of Metal Roll Forming Machines.

- We follow the direction of international popular development, follow the relevant international and national industry standards, high starting point, to provide users with Sheet Metal Roll Forming Machines that is in line with the development trend.

- Our metal roll forming machines are designed to be highly efficient and reduce production costs.

- Innovation is not only the inexhaustible power to promote the sustainable development of our company, but also the source of our company's survival and competitive advantage in the fierce market.

- Our metal roll forming machines are designed to be highly productive and cost-effective.

- We work closely with our customers to manufacture products that meet the ever-changing requirements of the market.

- Our machines are designed with safety in mind, ensuring a safe and secure work environment.

- We adopt a serious and rigorous business attitude, and we recommend only the most suitable Sheet Metal Roll Forming Machines for customers, so as to maximize processing efficiency and reduce processing costs.

- We have a reliable and efficient supply chain, ensuring timely delivery of our products.

- We always adhere to the concept of comfort, practicality, generous appearance and a variety of options in the development, research and production of our Sheet Metal Roll Forming Machines.

Hot Tags: sheet metal roll forming machines, IBR Sheet Roll Forming Machine, Standing Seam Roll Forming Machine, Rolling Shutter Roll Forming Machine, Fully Automatic Interchange C Z Purlin Roll, Beam Roll Forming Machine, Roll Forming Machine