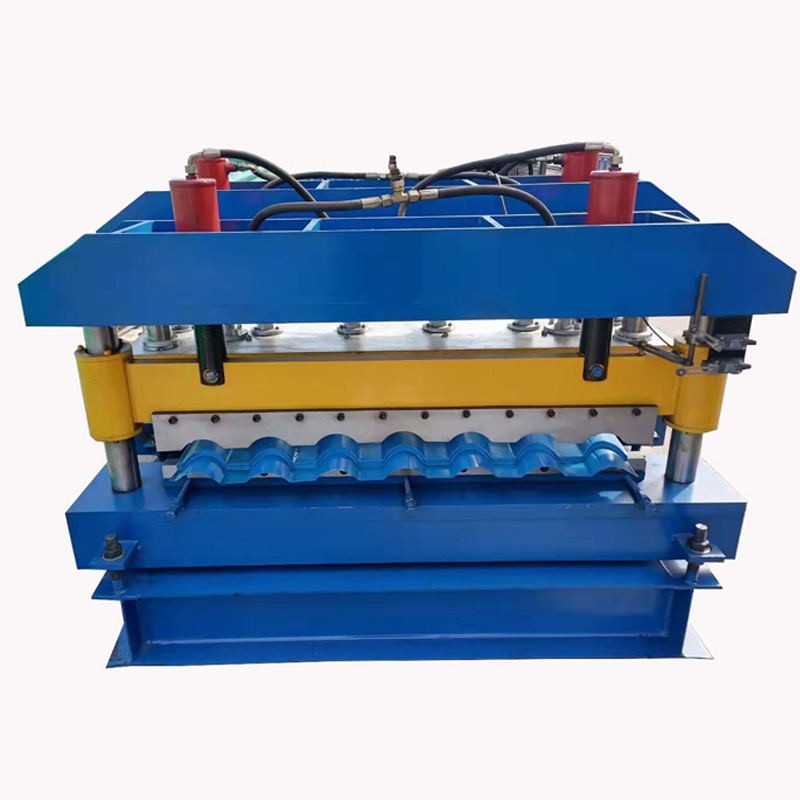

Steel Tile Roof Sheet Roll Forming Machine

Description

Steel Tile Roof Sheet Roll Forming Machine - The Ultimate Solution for Efficient Production

Introducing the Steel Tile Roof Sheet Roll Forming Machine - the game-changer in the world of roofing sheet production. Our machine is designed to provide high-efficiency, speed, accuracy, and quality output. We understand the need for cost-effective, durable, and aesthetically pleasing roofing solutions for the end-users in the construction industry. Our Steel Tile Roof Sheet Roll Forming Machine is the only tool you need to transform your roofing sheet production process and stand out from your competitors.

Design and Structure

Our Steel Tile Roof Sheet Roll Forming Machine is made of high-quality material, built to last and withstand harsh weather conditions. The machine is designed with efficiency in mind, and we have incorporated modern features to guarantee maximum output. The machine's structure is sturdy, and it's easy to operate, making it an ideal investment for small, medium, and large-scale manufacturers.

Production Capacity

Our Steel Tile Roof Sheet Roll Forming Machine has a production capacity that ranges from 18-25 meters per minute. This means that you can produce up to 2000-3000 square meters of roofing sheets per day. The machine's automatic cutting and driving features guarantee high precision and uniformity, reducing scrap rates and maximizing profits.

Versatility

The Steel Tile Roof Sheet Roll Forming Machine is versatile, capable of producing a range of roofing sheet sizes and types. Our machine is compatible with different types of raw materials, including aluminum, steel, and galvanized steel. The machine's flexibility will enable you to produce different designs of roofing sheets, depending on customer preferences and market demands.

Ease of Use

The Steel Tile Roof Sheet Roll Forming Machine is easy to operate, and we provide detailed manuals and training to our customers. The machine's automatic control system simplifies the operation and offers an unparalleled user experience. The machine's user-friendly interface means that you can quickly learn to operate it with minimal downtime.

Quality Output

Our Steel Tile Roof Sheet Roll Forming Machine guarantees quality output, and we take pride in our machine's ability to produce aesthetically pleasing and durable roofing sheets. The machine has a high precision rate, offering uniformity and accuracy in every cut. The machine uses modern technology to ensure the roofing sheets meet the industry's quality standards, and we can guarantee our customers 100% satisfaction.

Competitive Pricing

We offer competitive pricing for our Steel Tile Roof Sheet Roll Forming Machine, making it an ideal investment for small, medium, and large-scale manufacturers. Our pricing model is flexible and accommodates bulk purchase and payment plans.

Conclusion

The Steel Tile Roof Sheet Roll Forming Machine is a must-have investment for every manufacturer in the roofing sheet industry. Our machine guarantees efficiency, speed, accuracy, and quality output, all in one package. With our machine, you can increase your production capacity, reduce your scrap rate, and maximize your profits. Contact us today to get your hands on this revolutionary machine and take your business to the next level.

Introduction:

The Steel Tile Roof Sheet Roll Forming Machine use GI/PPGI as raw materials, and through a series of processes, we can produce metal roof panels. Secondly, the frequency converter of our product controls the motor speed, and the PLC system automatically controls the length and quantity, so the efficiency of this equipment is very high. What's more, continuous automatic production is an ideal equipment for cold roll forming industry. Finally, if you are interested in our products, please contact and communicate with us in time.

Feature

Each forming head of Steel Tile Roof Sheet Roll Forming Machine consists of a fixed housing and a sliding outer housing. Second, our mill stands will be arranged to position shafts mounted on tapered bearings. For the top shaft, the bearings are mounted in cartridge housings, the bottom shaft bearings are in machined holes in the housing, the bottom mandrel is held in place, and the top mandrel with the cartridge block can be raised in vertical rails machined in the housing or lower. Finally, all of our raw materials are imported components, which are strong and durable.

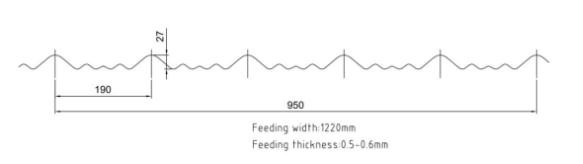

Drawing

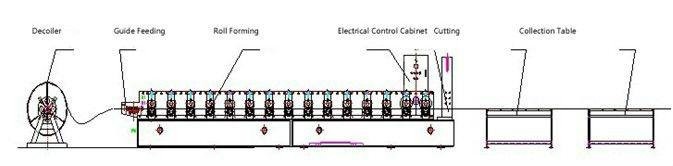

Technical Process

1220mm Coil →Guided Feeding →Roller Molding →Cutting to Length → Collection Table

Description

1. Feeding

Frame Structure: steel plate welded

Manual Pre-cutting Device

Roller Flatting System: let the feeding fluently

2. Roll Forming

The machine under Frame: 400 H-beam

Sidewall Plate Thickness: 16mm

Roller Station: 15

Shaft Diameter: 70mm

Main Shaft Material: 45# steel with finish turning

Roller Material: 45# Forging Steel with Chromium Plate

Chromium Wheel and Cycle Chain: 1 inch

Roll Forming Speed: 15-20m/min (adjusted with frequency changer)

3. Hydraulic Cutting System

It adopts a hydraulic drive and automatic location system to decide the dimension and cutting target.

Working Method: Stop to cut then post cut.

Hydraulic Tank: 1 set

Hydraulic Pump Station: 5.5kw

Cutting Length Tolerance: 10m+/-1mm

Cutting Material: Cr12 with quenched treatment 58-62 degrees.

4. PLC Control Cabinet

The target piece length is adjusted and the digit of it can be adjusted.

PLC Control Converter: Delta

Frequency Converter: Delta

Voltage: 3 phase/380V/50Hz (for confirmation)

5. Collection Table

Function: Collect the sheet

Length/set: 6 meters

Welded with square pipe

Why choose us?

- We offer a wide range of metal roll forming machines to suit various industries.

- Our company has the capability of independent production of Steel Tile Roof Sheet Roll Forming Machine, factory direct sales, large quantity from excellent.

- We are committed to ensuring our customers are satisfied with our products and services.

- We use scientific management methods to implement precision, accuracy, detail and strictness into each link.

- We constantly upgrade our machines to keep up with the latest advancements in technology.

- We insist on the business philosophy of "virtue-based, sincerity-based", take the market as our guide, take customer satisfaction as our quality target, forge ahead and make significant breakthroughs and developments in many aspects.

- We continuously strive to improve our products and services to meet the evolving needs of our customers.

- We continue to increase our R&D efforts, upgrade our process technology, improve our production efficiency, perfect our customer system and strengthen our quality control.

- Our metal roll forming machines are designed to meet the highest standards of performance.

- We adhere to the service concept of 'beginning with customer requirements and ending with customer satisfaction' to provide customers with better Steel Tile Roof Sheet Roll Forming Machine and superior services.

Hot Tags: steel tile roof sheet roll forming machine, Corrugated Sheet Making Machine, Sheet Metal Forming Machines, Purlin Forming Machine, Steel Roll Forming Machine, Double Layer Roll Forming Machine, Metal Roll Forming Machine