Steel Water Tank Making Machine

Description

Introduction

Steel water tanks are an indispensable part of our modern life, playing an important role in storing and supplying water for different purposes. However, their manufacture requires high precision, efficiency, and accuracy. The Steel Water Tank Making Machine from our company is your one-stop solution for producing high-quality steel water tanks quickly and cost-effectively. In this article, we will introduce you to our product, its features, advantages, and the reasons why you should consider it for your business.

Features

Our Steel Water Tank Making Machine boasts an array of advanced features that make it a reliable, efficient, and profitable tool for manufacturing steel water tanks. Some of the most salient features of our machine include:

1. High Production Capacity

Our machine has a high production capacity. It can produce up to 400 tanks per day. With such a high production capacity, you can meet the needs of a larger number of customers, make more profit, and expand your business.

2. Precision and Accuracy

Our machine is designed to ensure that every tank you produce is of high-quality, with the right dimensions, shape, and specifications. This is achieved through the use of advanced software technology, precision cutting tools, and rigorous quality control measures.

3. Easy to Use

Our Steel Water Tank Making Machine is easy to operate, even for those who have never operated any related equipment before. This is because it comes with a comprehensive user manual with step-by-step instructions on how to use it.

4. Cost-Effective

Our Steel Water Tank Making Machine is designed to help you save on production costs. It uses minimal power and requires low maintenance, which reduces the overall operational costs.

Advantages

The Steel Water Tank Making Machine from our company offers several key advantages over other similar products in the market. Some of these advantages include:

1. High-Quality Production

Our Steel Water Tank Making Machine is designed to produce high-quality steel water tanks with precision and accuracy. This means that you can be sure that every tank you produce conforms to the highest quality standards.

2. High Production Capacity

With the ability to produce up to 400 tanks per day, our machine makes it possible for you to meet the needs of a larger number of customers and expand your business.

3. User-Friendly and Easy to Operate

Our machine is easy to use, even for a first-time user. This is because we have designed it to be user-friendly and come with a comprehensive user manual to guide you on how to operate it.

4. Cost-Effective

Using our Steel Water Tank Making Machine means that you can produce high-quality tanks efficiently and cost-effectively. It uses minimal power and requires low maintenance, which reduces operational costs.

Why Choose Our Product

There are several reasons why you should choose our Steel Water Tank Making Machine over similar products. Some of these reasons include:

1. Quality

Our machine produces high-quality steel water tanks that meet or exceed industry standards. This means that you can rely on our product to provide you with tanks that are durable, reliable, and long-lasting.

2. Efficiency

Our machine is designed to increase your production capacity while reducing your operation costs. It is efficient, easy to use, and requires low maintenance, which means that you will save time, effort, and money.

3. Competitive Pricing

We offer competitive pricing for our Steel Water Tank Making Machine, which means that you can purchase our product at an affordable price without compromising on quality.

4. Excellent customer support

At our company, we pride ourselves on providing excellent customer support. Our experts are knowledgeable and always willing to help you with any queries or concerns you may have about our product.

Conclusion

In conclusion, our Steel Water Tank Making Machine is a must-have for any business that is involved in the production of steel water tanks. It is efficient, easy to use, produces high-quality tanks, and is cost-effective. With this machine, you can increase your production capacity, meet customer demand, and expand your business. Contact us today to learn more about our product and how it can benefit your business.

Introduction

Steel Water Tank Making Machine is widely used. All the rolls and shafts of this machine are electroplated to prevent rust. The PLC computer control system can control the operation of the machine. You can set the operating speed, product length, number of pieces and other parameters on the computer. It also has an emergency stop mode to quickly shut down the machine in the event of an emergency. We purchase the main components from very famous company in China to ensure the performance of the equipment, we can also customize and design according to your specifications and outline drawings. We have decades of production experience and provide the best pre-sales and after-sales service. If you have any questions, you can contact us for inquiry.

Main Features

1)Product name: Steel Water Tank Making Machine

2) Material of the profile: 195-235Mpa GI or carbon steel

3) Thickness range: 3-4mm

4) Main motor power: 60kw, AC motor, motor inside of main machine (Brand: Guomao of China) (according the final design)

5) Machine Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase

6) Roll station: about 20 stations (according the final design)

7) Roller material:Gcr15 bearing material chrome plated surface with hardness 58-62 degree ,CNC,

8) Shaft diameter: ¢150mm material: SAE1045 with quenching and tempering

9) Machine roll forming speed:18m/min

10) Transmission: by gear box 200*500 (outside is cast iron, surface needed polish and paint. Inside is 60# forge and press metal)

11) Roll former has leveling bolts in the base for adjust the leveling

12) Machine base frame adopt H beam welding steel

13) In the main roll forming machine have 2 buttons for urgency stop if happen any malfunction.

14) Machine adopt new station to make machine more strong

15) To avoid accidents, all of drive part adopt protect cover

16) Color of machine: Blue and yellow (or base on customer request)

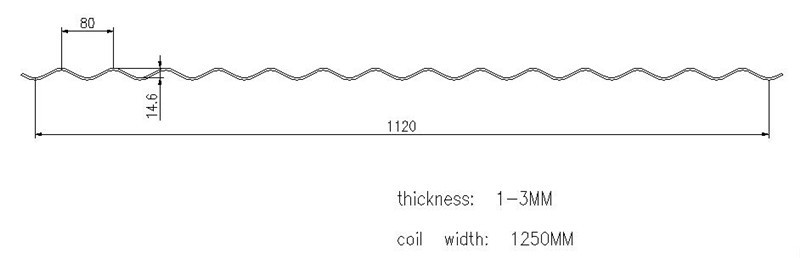

Profile Drawing

Details

10T hydraulic decoiler:

Steel coil width: from 1250 mm to 1500 mm;

Internal diameter of coil: variable, from 470 mm to 620 mm

Maximal out diameter: 1600mm

Maximum coil weight: 10000 Kg;

Oil cylinder dia: 120mm

Working speed: 0-15m/min adjustable

Main motor power: 7.5KW AC motor

Hydraulic power: 5.5kw

Speed controlled by frequency converter brand: Yaskawa

De-coiler should be with Loop control and hold down, and with baffle for forbid coil fall down

The decoiler has 4 segments

Forming Section

Material of the profile: 195-235Mpa GI or carbon steel

Thickness range: 3.0-4.0mm

Maximum production speed: not less than 18 meters per minute (for non-perforated profiles, excluding cutting)

Main motor power: 60kw, AC motor, motor inside of main machine (Brand: Guomao of China)

Machine Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase

Roll station: 20 stations

Roller material: Gcr15 bearing material chrome plated surface with hardness 58-62 degree, CNC

Shaft diameter: ¢150mm material: SAE1045 with quenching and tempering

Transmission: by gear box 200*500 (outside is cast iron, surface needed polish and paint. Inside is 60# forge and press metal)

Punching:

The punches and dollies will be CR-12, hardness HRC 58-62 and chrome coating both punches and dolies should be easily replaceable without requiring disassembly of complete units.

The whole punching operation should be automated and controlled by a program installed in the PC which is located in the operator's console.

Hydraulic power: 5.5kw

Working pressure: 12-16Mpa

Cutting:

Machine adopt hydraulic cutting

Cutting after forming: Cut the sheet after roll forming to required length

Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start.

Material of blade: CR12with heat treatment

Length measuring: Automatic length measuring

Tolerance of length: 4700mm+/- 2mm

Auto Stacker and Transmission Table:

Take the sheet by air compressor, 5.5KW (provide by customer)

Air cylinder swing arm size: 40mmx80mm

Transmission power: 4kw AC motor

Stacker length in 12m, transmission table length in 25m

Drive of transmission by 1.0inch double line chain

Transmission roller: ASTM1045 with chrome, diameter of roller is in 80mm

Carrying capacity: maximal 5000Kgs

Length of capacity: 500-12000mm

The maximal stacker height: 300mm

Hydraulic Station:

Hydraulic power: 11kW

Working pressure: 20-25Mpa adjustable

Solenoid valve: 3 group

Hydraulic oil: 46# hydraulic oil

Color: Blue (or base on customer request)

Control Carbinet:

1) Programmable setting of profile length and quantity

2) Automatic stopping of the equipment after completion of the cutting programme.

3) Operating system language: English and Chinese

4) Computer used to control length & quantity. Machine will automatically cut tolength and stop when required quantity is achieved

5) PLC brand: Panasonic

6) Frequency converter brand: Yaskawa, quantity: 1

7) Touch screen: Taiwan Weinview

Why choose us?

- If you're in need of a reliable supplier of Machine To Make Metal Roofing products, look no further than us.

- In the new world development situation, our company is clear about its own sense of social responsibility.

- Our goal is to provide our customers with cost-effective Machine To Make Metal Roofing solutions without sacrificing quality or service.

- We combine relevant industry knowledge and process requirements to provide our customers with highly reliable Steel Water Tank Making Machine solutions.

- From design to manufacturing to delivery, we ensure that every aspect of our Machine To Make Metal Roofing products and services is top-notch.

- The company is one of the most complete industry chain enterprises in the xxx industry.

- We stand behind every Machine To Make Metal Roofing product we sell and guarantee your satisfaction.

- Under the market economic system, enterprises are microeconomic entities that operate independently and are responsible for our own profits and losses.

- We take pride in our reputation for supplying the highest quality Machine To Make Metal Roofing products and services.

- Our organization successfully attained IS9001 Certification and European CE Certification of Steel Water Tank Making Machine.

Hot Tags: steel water tank making machine, Steel Silo Rollformer, Highway Guardrail Machine, Self Lock Roof Panel Roll Forming Machine, Steel Silo Roll Forming Machine, Beam Purlin Roll Forming Machine, Metal Roll Former