Steel Silo Making Machine

Description

Introduction

The Steel Silo Making Machine is a state-of-the-art equipment designed to produce high-quality steel silos used for storing grains, cement, and other bulk solids. Its innovative and efficient design guarantees quick, safe and cost-effective production of steel silos of different sizes and shapes. As a manufacturer located in China, our company is committed to providing top-notch quality machines to merchants worldwide who seek to maximize their profit potential and enhance customer satisfaction.

Features and Advantages

The Steel Silo Making Machine is an advanced equipment designed and fabricated using the latest technology in the industry. Among its key features and advantages include:

1. High Precision

The equipment is designed with high precision allowing for accurate and consistent production of steel silos that match the clients’ specifications. The machine is fitted with intelligent control systems that guarantee smooth and error-free operation.

2. Customizable

Our Steel Silo Making Machine is highly flexible, which makes it easy to customize the shape and size of the steel silos. This means that our clients can produce silos that match their specific storage needs, whether it’s for cement, grain, or any other bulk solid.

3. High Production Capacity

Our machine is designed with high production capacity, which means that clients can produce a large number of steel silos within a short period. This ensures that merchants can complete their orders faster and deliver to their customers promptly, resulting in increased customer satisfaction.

4. Cost-Effective

The machine is designed with cost-effectiveness in mind. Our clients can produce steel silos that are not only of high quality but also at a lower cost compared to other machines in the market. This allows them to maximize their profit potential while still providing high-quality products to their customers.

5. Easy to Operate

Our Steel Silo Making Machine is user-friendly, making it easy for operators to understand and use. It is designed with a touch screen control system, which means that operators can easily adjust the settings to match the clients’ specifications.

6. High-Quality Output

The machine is designed to produce high-quality steel silos that are durable, reliable, and can withstand harsh weather conditions. This ensures that customers get value for their money and that the merchants’ reputation for delivering high-quality products is maintained.

Applications

Our Steel Silo Making Machine is commonly used for a variety of applications, including:

1. Grain Storage

Grain storage is one of the key applications of our Steel Silo Making Machine. The machine can produce steel silos that are perfect for storing grains for extended periods, ensuring that they remain fresh and of high quality.

2. Cement Storage

Cement is another application of the Steel Silo Making Machine. Our machine is designed to produce steel silos that can store cement for extended periods without getting damaged or compromised.

3. Other Bulk Solids

Our machine can also produce steel silos that are perfect for storing other bulk solids like coal, woodchips, and many others. This makes it a versatile machine that can cater to a wide range of customer needs.

Conclusion

In conclusion, our Steel Silo Making Machine is a game-changer in the steel silo manufacturing industry. Its state-of-the-art design and efficient operation guarantee prompt, reliable, and cost-effective production of steel silos for various applications. As a manufacturer located in China, we are committed to providing top-quality machines to our clients worldwide, allowing them to maximize their profit potential and deliver high-quality products to their customers.

Introduction

The Steel Silo Making Machine is fully automatic, so the operation is very simple, which greatly saves manpower and material resources. The machine integrates forming, punching and cutting. The finished products can be directly assembled without secondary processing. The machine has high accuracy and small plate error. The surface of the machine has been polished, so it is exquisite and beautiful. Fully automatic computer operation is adopted, so the machine has fast reaction speed. The machine has stable performance, so it runs smoothly and noiseless. The machine adopts high-end touch screen control system, so that the operator can better understand various parameters and production conditions. Our products are tested before leaving the factory, and only those qualified can be delivered, so the quality is absolutely guaranteed.

Features

1. The price of the Steel Silo Making Machine is favorable and reasonable, and the performance is higher than the price.

2. We deliver goods in time, have a perfect distribution system, and have relatively stable logistics partners.

3. We have our own factory. From design, research and development to the delivery of goods, we have gone through layers of checks, so the quality is guaranteed.

4. We support customized services, and various styles and models can be formulated to meet your different needs.

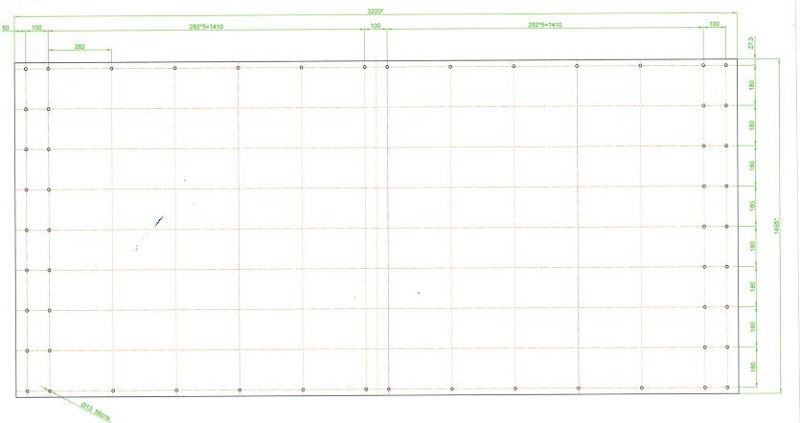

A. Profile Drawing

Picture 1 section of profile

B. Technical Process/Sketch

Decoil → feed → guided → roll-form → bottom punch → lip adjust → curve → cutting → collection table (see the detail drawing)

C. Basic Parameters of Finished Product

1. Thickness of panel: 1.5mm zincalume sheeting G300.

2. Mechanical performance: yield strength 340MPa, tensile strength 470MPa.

3. Coil width: 1495mm.

4. Inner diameter of coil: φ460-550mm.

5. The width of finished profile width after formed: (As per required)

D. Main configuration and technical proposal

(a) Passive decoiler 10T

During normal processing, the decoiler works passively.

The capacity of this decoiler is around 10T, the width of coil is 900mm.

(b) Level system: Five-roller leveler.

(c) Roll-former

1. The construction of roll-former: wall frame.

2. Transmission way: motor-chain drive-chain -main shaft

3. Roll-forming station: 18 stations

4. Main power: 15KW 415V 50HZ 3-phase Brake Motor

5. Main reducer: Cycloidal Pinwheel Reduction Box: 33-43-15KW.

6. Material of rollers: qualified 45# steel, galvanization treatment, to increase the smooth of roller surface and make sure of its service time and also avoid surface damage of the sheet.

7. The shape of rollers is designed through German design software COPRA, and processed on the precision NC machine. The surface of rollers is polished

8. The diameter of shaft for rollers: φ85, 45# steel quenched and tempered.

9. Punching

Customer Visit

Our Workshop

Why choose us?

- When you choose us as your supplier, you can be confident that you are getting the best Machine To Make Metal Roofing products and services available.

- We have our research and development team to bring out various kinds of products and solutions to meet the customers' requirements, we take each step very carefully to assure our product quality.

- We are your one-stop-shop for premium Machine To Make Metal Roofing products and services.

- We hope to constantly surpass ourselves, surpass others, and strive to achieve new leaps and breakthroughs.

- Our factory provides top-quality Machine To Make Metal Roofing products and services with competitive prices.

- We are good at using democratic methods and open means to mobilize staff morale, stimulate staff motivation and unite staff strength.

- We craft our Machine To Make Metal Roofing products with the highest quality materials to guarantee their durability and longevity.

- Our expertise and continuous research in product design, quality management and advanced technology have made our Steel Silo Making Machine popular in the market.

- Our skilled team ensures that each Machine To Make Metal Roofing product is crafted with the utmost care and precision.

- Meeting customers' expectations is our pursuit, while providing customers with quality Steel Silo Making Machine is our commitment.

Hot Tags: steel silo making machine, Steel Silo Roll Forming Machine, Corrugated Roof Sheeting Machine, Ibr Roof Sheet Forming Machine, Purlin Forming Machine, Cold Roll Forming, Rolling Shutter Roll Forming Machine