Roof Making Machines

Description

Roof Making Machines: The Perfect Solution for Your Business

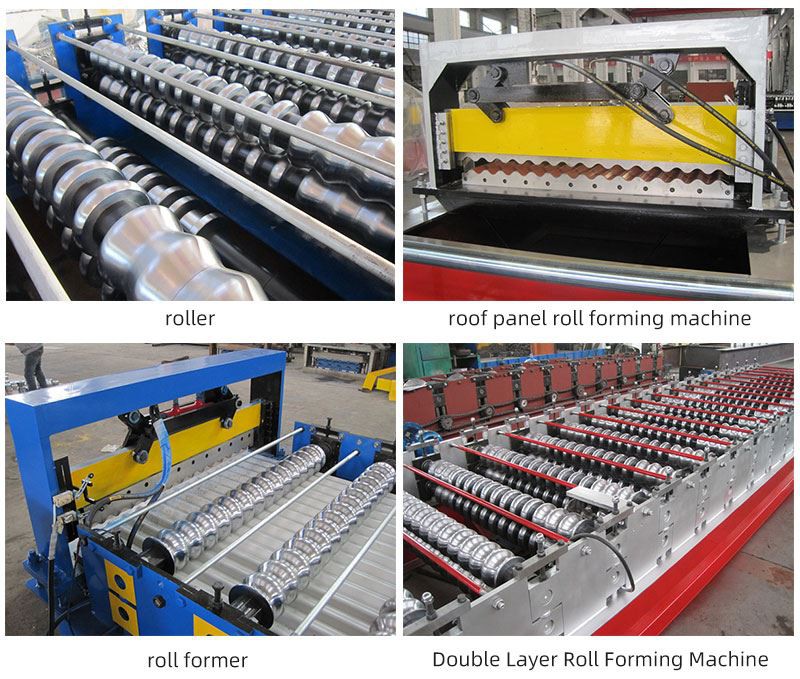

Introducing our latest product, the Roof Making Machine – a unique and high-quality manufacturing equipment designed to meet the ever-increasing demand for affordable and long-lasting roofing materials. This innovative product is ideal for businesses in the roofing industry as it simplifies the roof making process, making it faster, more efficient, and more manageable than ever before.

Our Roof Making Machines come with an array of features that make them a must-have for any roofing business. They are designed to produce a variety of roofing materials such as steel, aluminum, and zinc, among others. These machines also come in different sizes and can be customized to fit the specific needs and requirements of our customers. Whether you need a large machine for mass production or a smaller one for a small-scale business, we have got you covered.

One of the defining features of our Roof Making Machines is their ease of use. These machines are user-friendly, and even people with limited technical skills can learn to operate them in a short time. Therefore, you can have less skilled employees running your production line, resulting in significant cost savings for your business.

Our machines boast of a high level of precision, which guarantees that every piece of material produced is of the same quality, regardless of the batch size. The accuracy of the machine means that there is less waste, and you have less scrap metal, resulting in significant cost savings.

Another key feature of our Roof Making Machines is the consistency of the products produced. This means that you can rely on the quality of roofing materials that these machines produce, and you can be sure that all the roofing materials you produce will meet or exceed the required standards. This level of consistency is essential in building a brand that customers can trust. Therefore, you can guarantee your clients high-quality roofing materials every time, leading to customer loyalty and repeat business.

A significant advantage of our Roof Making Machines is their durability. We use high-quality materials to manufacture our machines, which ensures that they can withstand heavy usage and last for many years. They are also easy to repair and maintain, reducing downtime and increasing productivity.

Our Roof Making Machines are designed with safety in mind. They have several safety features that protect users from potential hazards when operating the machines. The machines are also equipped with an automatic stop system, which stops the machine when a problem occurs, preventing damage to the machine and ensuring user safety.

Our machines are also extremely versatile, and they can produce a variety of roofing materials such as metal sheets, tiles, and panels. This flexibility ensures that you can meet the needs of your clients by producing different types of roofing materials, resulting in an expanded customer base and increased revenue.

In conclusion, our Roof Making Machines are a game-changer for businesses in the roofing industry. With their ease of use, accuracy, consistency, durability, versatility, and safety features, our machines offer you the perfect solution to increase productivity, reduce costs, and meet the ever-growing demands of your customers. Do not hesitate to contact us today to order your Roof Making Machine and take your business to the next level.

Introduction

The Roof Making Machines have strong power and long service life. The product adopts full automatic control, so it is simple to operate, time-saving and labor-saving. The fuselage is made of high-quality steel by precision welding. The roof board made by this machine has the characteristics of high wave crest and high strength, and its installation is safe, reliable and convenient. The waterproof and anti riot performance of the roof board is also strong. To sum up, the machine is highly automated, low-cost, durable and easy to assemble. We have been engaged in this industry for many years, with rich experience and mature technology, so we can ensure that the machines we produce have good quality. If you have any questions, you can also consult us at any time.

Features

1. The Roof Making Machines are precision welded, so they have low noise, durability and long service life.

2. The product adopts full automatic control, so it runs smoothly and easily.

3. It is manufactured by rolling forming process, so the welding is precise and free of defects.

4. There are a variety of specifications and models, which can also be customized to meet customer needs.

| Raw Material |

Feeding with |

Up layer 1000mm |

|

Effective width |

Up layer 820 |

|

|

Thickness |

0.3-0.8mm |

|

|

Main Forming Machine |

Roller material |

45# steel plated with chrome |

|

Diameter of shaft |

70MM |

|

|

Roller station |

16-18 |

|

|

Main Configuration |

Main motor power |

5.5kw |

|

Hydraulic station power |

4kw |

|

|

Control system |

PLC (Mitsubishi) |

Why choose us?

- Our skilled team of professionals is dedicated to producing Metal Sheet Making Machines that are both effective and reliable.

- The market recognition of our Roof Making Machines has been steadily increasing benefited from the in-depth advancement in the field of intelligent manufacturing.

- We take pride in our ability to provide our customers with the best possible Metal Sheet Making Machines at a competitive price.

- We have done a good job in strategic layout and business structure optimization.

- Whether you need a new machine or spare parts for an existing one, we have you covered with our range of Metal Sheet Making Machines.

- Our global customers have high expectations of our company, and the variety of opportunities for personal learning and development allows us to meet the highest public expectations.

- Our Metal Sheet Making Machines are designed to save you time and money while delivering outstanding results.

- Our company adheres to the "customer first, realistic and innovative" thread, and always puts the needs of the market and customers first. Our united and enterprising team will definitely provide more, better and more cost-effective Roof Making Machines to meet customer needs in the future growth path.

- We are committed to providing our customers with Metal Sheet Making Machines that are versatile, efficient, and cost-effective.

- We analyzed the core competitiveness of our Roof Making Machines, the advantages and disadvantages of our products in marketing conditions, the opportunities and challenges in the external market, and constantly improve ourselves.

Hot Tags: roof making machines, Closed Type Floor Decking Roll Forming Machine, Roll Forming Machine for Corrugated Sheet, Corrugated Forming Machine, Steel Silo Making Machine, Standing Seam Roll Forming Machine, Sheet Roll Forming