Roofing Sheet Making Machine

Description

Introduction:

As a manufacturer located in China, we are proud to introduce our high-quality roofing sheet making machines that have been designed to meet the needs of merchants who want to offer exceptional roofing solutions to their customers. Our machines are built with the best quality materials, ensuring that they are durable, dependable, and able to produce top-notch roofing sheets that meet and exceed industry standards.

Our roofing sheet making machine is a cost-effective solution for merchants who want to produce high-quality roofing sheets at an affordable price point. Whether you're in the construction industry or just an entrepreneur in need of a reliable roofing sheet production machine, look no further, our machine is perfect for your needs.

Key Features:

One of the key benefits of our roofing sheet making machine is its simplicity, which is easy to operate and requires little training to use. The machine comes with a user-friendly manual, and our technical support team is always ready to assist customers with any questions or concerns.

Another feature that makes our roofing sheet making machine stand out is its ability to produce a wide range of roofing sheets, from corrugated galvanized iron (CGI) sheets, metal tiles, to standing seam metal roofs, just to mention a few. Plus, our machines can create roofing sheets of different shapes, thicknesses, and sizes, which makes them perfect for custom roofing projects.

Our machines are built with high-quality materials that are designed to withstand harsh environments and withstand wear and tear. Thus they require minimal maintenance, ensuring that they run efficiently, minimizing production downtime.

The machine is automated, so there's no need for manual intervention throughout the production process. Auto-stacking systems are also available to ensure that the roofing sheets are stacked correctly, reducing waste and saving time.

Our Product Guarantee:

We stand by our products' high quality, and our roofing sheet making machine comes with a one-year warranty. We also provide training and support to our customers to ensure that their experience with our machine is hassle-free.

Support Services:

We carry a full stock of spare parts, including electrical and mechanical components, just in case a replacement part is needed. Furthermore, we pride ourselves on providing prompt customer service and technical support to help ensure your machine's durability and optimal performance.

Conclusion:

At this point, we hope you have a better understanding of our roofing sheet making machine and how it can enhance your business offerings. Our roofing sheet making machine is competitively priced, user-friendly, and produces high-quality roofing sheets. Contact us for more information about our roofing sheet making machine and let us help you elevate your roofing business to the next level.

Introduction

This Roofing Sheet Making Machine is a kind of equipment for automatic mass production of roof panels by rolling forming and other processes. It is widely used in various industries, civil buildings and other fields, and has the advantages of beautiful appearance and durability. This machine is equipped with a sensitive PLC control system, which enables it to carry out high-speed production according to your set parameters and helps you to obtain a steel plate with a smooth and beautiful surface without any scratches. In addition, it can be customized and designed according to your ideal specifications and outline drawings, so as to meet your more needs.

Features

The Roofing Sheet Making Machine adopts compact design, compact and durable, with high strength, which can effectively save manufacturing cost and space. At the same time, it can use galvanized steel plate, colored steel plate or aluminum plate as material plate to process materials of various sizes and thicknesses, so that it has a wide range of applications. In addition, its computer display control system is simple to operate, stable and reliable to run, and can reduce the maintain times during long-term use, which helps to save costs.

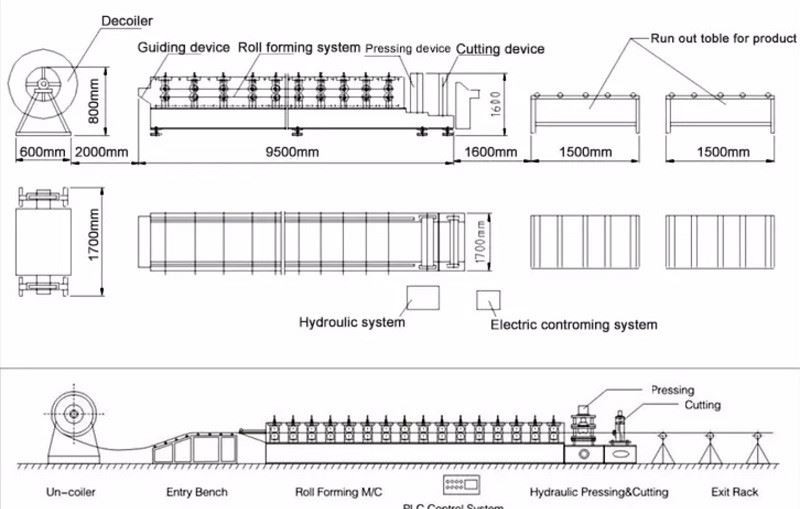

Layout Drawing

|

High quality rollers will help to produce the beautiful and high quality profile. That will satisfy your customers. |

|

|

The hydraulic system will be installed on the main roll forming machine. The important is that we install the cooling system on hydraulic oil pump, then it can support the long time working in a high temperature. Then it can improve the working ability. |

|

|

We adapt the PLC for the control system, it will be so much helpful for users to handle the machine. The control system will be in charge of the working condition like the speed, cutting length and cutting quantity. The display screen will be the touch screen or the text screen, the language can be English, or as required. |

|

|

It is derived by a Gear Pump. After filling the hydraulic oil into the hydraulic oil tank, the pump could drive the hydraulic cylinder to realize the cutting function. |

Why choose us?

- At our factory, you'll find a team of highly skilled professionals dedicated to delivering high-quality Metal Sheet Making Machines.

- We stimulate the enthusiasm, initiative and creativity of employees, enhance the cohesion and centripetal force of the enterprise, and create a united and courageous staff team.

- Our skilled team of professionals is dedicated to producing Metal Sheet Making Machines that are both effective and reliable.

- In edict to create an environment and driving force for the sustainable development of our company, we will make every effort to promote institutional innovation and corporate culture construction.

- Our focus on quality and customer satisfaction has enabled us to build a strong reputation in the industry.

- Our company adheres to market demand as the guide, and customer requirements as the driving force, and constantly innovates to ensure the satisfaction of the majority of users. In line with the concept of honest management, we continue to improve the quality of Roofing Sheet Making Machine. We hope to look around the world and create world-class services and high-quality products for our customers.

- We take pride in building long-lasting relationships with our customers, providing them with the best possible Metal Sheet Making Machines and support.

- Our products enjoy a good reputation in the industry, and our sales network is expanding all over the world.

- No matter what your requirements are, we can customize our Metal Sheet Making Machines to meet your specific needs.

- The company will continue to uphold its own corporate culture, adhere to its mission and goals, and serve customers.

Hot Tags: roofing sheet making machine, Sheet Making Machine, Glazed Tile Roof Sheet Roll Forming Machine, Rolling Shutter Rollformer, C Purlin Rollformer, Metal Roll Forming Machine, Purlin Roll Former