Corrugated Sheet Making Machine

Description

Corrugated Sheet Making Machine Introduction

Welcome to our manufacturing company, located in China. We specialize in producing and delivering high-quality machinery to merchants and businesses located throughout the world. Our Corrugated Sheet Making Machine is a top-of-the-line product designed to assist businesses in creating corrugated sheets for use in packaging, shipping, construction, and more.

Our Corrugated Sheet Making Machine is a versatile and efficient machine that can produce multiple types of corrugated sheets. The machine is fully automated, which allows for a high level of productivity and efficiency. Our machine also allows for customized sheet thickness and width to meet different production requirements.

There are several reasons why our Corrugated Sheet Making Machine is an ideal product for merchants and businesses. Firstly, it's easy to operate and maintain due to its simple design. It's also very durable and reliable, ensuring longevity and minimal downtime. Secondly, our Corrugated Sheet Making Machine ensures precision and accuracy during the production process for precise and high-quality sheets.

Another important advantage of our Corrugated Sheet Making Machine is its vast range of applications. The corrugated sheets produced by our machine can be used to create various packaging materials, including boxes, cartons, and other products. It's also used in the construction industry as roofing and siding for buildings. Additionally, it's used in the automotive and electronic industries as protective packaging.

Product Features

1. High-Quality Components

Our Corrugated Sheet Making Machine is made of high-quality components that ensure high performance and durability. The use of high-quality components also ensures a longer lifespan, reducing the need for frequent replacements.

2. User-Friendly Design

Our Corrugated Sheet Making Machine is user-friendly, as it requires little to no experience regarding operation and maintenance. This user-friendly design also speeds up the production process, ensuring that work is completed efficiently.

3. Automated System

The machine is equipped with a fully automated system for greater precision and efficiency during the manufacturing process. The automated system also means that the machine can operate 24/7, ensuring that orders are completed quickly.

4. Energy-Efficient

Our Corrugated Sheet Making Machine is energy-efficient, consuming less electricity than other machines. This attribute makes our machine safer to operate and more environmentally friendly.

5. Customizable Plate Dimensions

Our machine allows for the creation of custom-sized corrugated sheets, depending on clients' preferences. We provide different molds and plates for different corrugated sheet sizes.

6. High Production Capacity

Our Corrugated Sheet Making Machine has a high production capacity, producing up to a maximum capacity of 15,000 sqm per day.

Conclusion

In conclusion, our Corrugated Sheet Making Machine is one of the best machines in the market, allowing clients to produce high-quality and precision corrugated sheets for various applications. Operating our Corrugated Sheet Making Machine is an investment in your business's future, as it guarantees higher levels of productivity, efficiency, and profitability. Clients can rest assured that our machine comes with a warranty to ensure satisfaction, and our customer support team is always available to answer any queries regarding operations.

Please feel free to contact us regarding our Corrugated Sheet Making Machine or any other machinery manufacturing services we offer. We would be more than delighted to answer your queries and provide you with our services.

Introduction

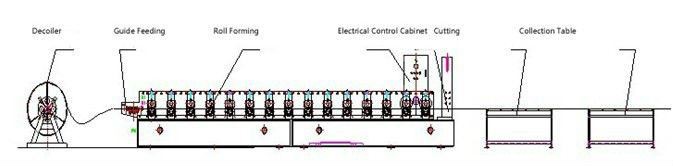

This Corrugated Sheet Making Machine is widely used in long-span factories, warehouses, office buildings and other fields. It can produce different shapes of steel plates according to customers' profile drawings and requirements, including corrugated plates and trapezoidal plates. This machine is composed of automatic uncoiler, feeding guide rail, rolling forming unit and so on. It has the characteristics of exquisite and compact appearance and won't take up too much space. At the same time, it is made of durable materials and equipped with advanced technology to ensure accuracy, efficiency and safety.

Features

The Corrugated Sheet Making Machine adopts multi-roll design, which can create plates with different sizes and thicknesses to meet the specific needs of customers. All parts of the machine are precisely machined and the surface is chrome-plated, so that surface scratches can be avoided during machining and the service life can be prolonged. In addition, the machine is equipped with an efficient hydraulic post-cutting device with post-cutting, stop-cutting and three-piece cutter design, which can ensure the clean section of steel and avoid deformation problems.

Applications

The finished products are used as the roof and walls of gymnasiums, airports, theaters, factories, warehouses, garages, exhibition, centers etc.

1. Main Motor Power: 5.5KW

2. Cycloidal Pinwheel Reduction Box: BWD27-43-5.5KW

3. Drive Sprocket: Pitch of 25.4mm

4. Rack Wall: I-beam welding adopted and distressing

5. Unit Dimensions: 7.3m long, 1.2m wide and 1m high

6. Production Speed: 0-12m/min

7. Axle Diameter: 75mm and thermal refining

8. Bulging Axle Diameter: 75 mm and thermal refining

9. Bulging Roll Material: 45# Steel

10. Heat Treatment of Bulging Roll: 45# Steel

11.Number of Forming Stations: 18

12. Forming Shear Blade Material: 45# Steel

13. Heat Treatment of Sharing Blade: HRC58°C-62°C

14. Rolling Thickness: 0.4-0.8mm

15. Rolling Material: 45# Steel

16. The single surface of Cr electroplating rollers: 0.05mm

17. The product dimensions is up to the PRC's standard for Construction Product: GB/T12755-91

18. Scale Accuracy: 10m±2mm

Note: If you have any special requirements, please contact us for further and correct scheme. Thanks!

Why choose us?

- You can trust us to deliver top-quality Metal Sheet Making Machines, backed by excellent customer service.

- Our company has won the praise of customers with its novel product design, unique customized solutions, high-quality product guarantee and perfect service.

- With our vast experience and expertise in the field of metal sheet manufacturing, we can offer you the best solutions and services.

- The company adheres to the tenet of "survive by quality and development by service" and the concept of "integrity, pragmatism, innovation, and progress". We welcome new and old customers to come to technical exchanges and cooperation.

- With our Metal Sheet Making Machines, you can expect outstanding quality and uncompromising performance.

- After years of unremitting exploration and practice, we have gradually accumulated wisdom, science and technology, and cultural multiple strengths.

- We take pride in building long-lasting relationships with our customers, providing them with the best possible Metal Sheet Making Machines and support.

- We regard Corrugated Sheet Making Machine quality as the root of enterprise survival and service quality as the bridge to our success.

- Our Metal Sheet Making Machines are designed to meet the demands of today's fast-paced manufacturing environment.

- We start from the real needs of enterprises and establish an effective and integrated material market through various channels.

Hot Tags: corrugated sheet making machine, Standing Seam Roll Forming Machine, Iron Sheet Corrugated Making Machine, Shutter Door Forming Machine, Metal Roll Former, Double Layer Roll Former, Rain Gutter Roll Forming Machine