Corrugated Roof Sheeting Machine

Description

Corrugated Roof Sheeting Machine - A Revolutionary Solution to Meet Your Roofing Needs

Are you looking for a reliable and efficient way to produce high-quality corrugated roofing sheets? Do you want to explore new opportunities in the roofing industry? If so, look no further than our Corrugated Roof Sheeting Machine - the ultimate solution for all your roofing needs.

At our manufacturing facility in China, we have developed a state-of-the-art machine that is capable of producing high-quality and durable corrugated roofing sheets. Our machine is designed to be user-friendly, efficient, and cost-effective - allowing you to produce top-quality sheets in large volumes with ease.

What Makes Our Corrugated Roof Sheeting Machine Stand Out?

There are several reasons why our Corrugated Roof Sheeting Machine stands out from other machines in the market. Below are some of the aspects that make our product unique and attractive to merchants:

1. High Quality

Our machine is designed to produce high-quality corrugated roofing sheets that are durable, sturdy, and resistant to harsh weather conditions. We use only the best quality materials and components to build our machine, ensuring that it is reliable and long-lasting.

2. Efficient

Our machine is incredibly efficient, allowing you to produce a large volume of roofing sheets in a short amount of time. It is equipped with state-of-the-art technology that ensures precision and accuracy in the production process, resulting in consistent and high-quality output.

3. User-Friendly

Our machine is designed to be user-friendly, meaning that you do not need to have any technical knowledge or expertise to operate it. We provide detailed instructions and training to help you get started, and our customer support team is always on hand to assist with any queries or issues.

4. Cost-Effective

Investing in our Corrugated Roof Sheeting Machine is a cost-effective solution for producing roofing sheets, as it eliminates the need for manual labor and reduces the overall production costs. It is a smart investment for merchants looking to expand their business in the roofing industry.

5. Versatile

Our Corrugated Roof Sheeting Machine is versatile and can produce a wide range of roofing sheets, including those made from different materials and sizes. This versatility enables you to cater to the diverse needs of your customers and expand your product range.

Why Choose Our Corrugated Roof Sheeting Machine?

There are several reasons why you should choose our Corrugated Roof Sheeting Machine for your roofing needs. Below are some of the benefits that you can enjoy when you invest in our product:

1. High-Quality Products

Our machine is designed to produce high-quality and durable roofing sheets that meet and exceed industry standards. You can be assured of reliable and long-lasting products that will provide your customers with the best value for their money.

2. Increased Productivity

Our machine is incredibly efficient and can produce a large volume of roofing sheets in a short amount of time, allowing you to increase your productivity and meet the demands of your customers.

3. Reduced Labor Costs

Investing in our Corrugated Roof Sheeting Machine reduces the need for manual labor, thus reducing your overall production costs. This makes it a cost-effective solution for merchants looking to expand their business in the roofing industry.

4. Versatility

Our machine is versatile and can produce a wide range of roofing sheets, enabling you to cater to the diverse needs of your customers.

5. Simple and Easy to Use

Our machine is designed to be user-friendly, meaning that you do not need any technical expertise to operate it. Our customer support team is always on hand to assist with any queries or issues you may encounter.

Conclusion

Our Corrugated Roof Sheeting Machine is a revolutionary solution that can help you meet your roofing needs in an efficient, cost-effective, and reliable manner. We are confident that our product will help you expand your business and cater to the diverse needs of your customers.

Investing in our Corrugated Roof Sheeting Machine is a smart choice for merchants looking to expand their business in the roofing industry. Get in touch with us today to learn more about our product and how it can benefit your business.

Introduction

This Corrugated Roof Sheeting Machine is a machine for producing corrugated roof sheets, which can process and press steel plates into corrugated roof panels through a series of processes. It is usually used in construction, industry and agriculture. It is made of high-quality metal materials, and its surface is treated with antirust powder, which makes it corrosion-resistant and can withstand the influence of bad weather conditions. In addition, its precise computer control system enables it to bend various thin or thick plates, providing high productivity and long-term reliability.

Features

This Corrugated Roof Sheeting Machine can produce high-quality steel silo board with excellent precision and accuracy, ensuring firmness and durability, and can withstand harsh industrial environment. The machine uses advanced technology to ensure that all materials are produced according to high standards, so that these steel plates have uniform specifications and good processability. In addition, the movement of the bending roller is hydraulic, which has the characteristics of high rolling speed and low energy consumption cost, and can improve the stability of processing.

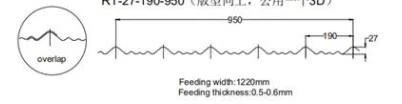

1. Profile Drawing

2. Process Drawing

Passive decoiler — Feeding — Roll forming –- Cut to length -- Collection

3. Technical Information

3.1 Main power: 5.5kw

3.2 Reducer: BWD22-43-5.5KW

3.3 Transmission chain: 25.4 pitch

3.4 Wall frame thickness: 16mm

3.5 Machine size: about 7M*1.4M

3.6 Forming speed: 0-12m/min

3.7 Shaft O.D: φ80mm

3.8 Forming station: About 16

3.9 Blade material: Cr12

3.10 Heat treatment for blade: HRC HRC58-62°

3.11 Rolling thickness: 0.17-0.6mm

3.12 Length: 3m/±1.5mm

3.13 Roller material: 45# steel

4. Electrical Components and Hydraulic

4.1 Inverter: Thinget

4.2 PLC: Thinget

4.3 Operation panel: MCGS

4.4 Low electrical components: Deli

4.5 Encoder: Omron

4.6 Hydraulic station: 3kw

4.7 Oil pump: YBI-10

Why choose us?

- Our Metal Sheet Making Machines are built to the highest standards of quality, ensuring their reliability and effectiveness.

- We adhere to the principle of valuing contracts and keeping promises, have a sense of responsibility and honor for the society, and shape the corporate image with practical actions.

- Our Metal Sheet Making Machines are easy to operate and maintain, keeping your production running smoothly and efficiently.

- Our company provides customers with full care services to meet the requirements of production, processing, customization, purchasing, after-sales, etc., saving costs for customers and solving customer needs.

- Our Metal Sheet Making Machines are manufactured to the highest quality standards to ensure your satisfaction.

- We are committed to developing and promoting energy-efficient and resource-efficient products and providing superior Corrugated Roof Sheeting Machine and services to society.

- Our Metal Sheet Making Machines are designed to be durable, reliable, and efficient, providing years of trouble-free service.

- Enterprise service concept: customer satisfaction is our highest honor.

- Our Metal Sheet Making Machines are designed to be efficient and productive, helping you streamline your manufacturing process.

- We serve our valued customers with innovative Corrugated Roof Sheeting Machine, superior service and continuously improved quality.

Hot Tags: corrugated roof sheeting machine, Corrugated Roll Forming Machine, Corrugated Barrel Type Machine, Iron Roof Tile Making Machine, Corrugated Forming Machine, Rolling Shutter Making Machine, Sheet Roll Forming