Steel Roll Forming Machine

Description

Introduction:

As a leading manufacturer located in China, we are thrilled to introduce our latest product, a Steel Roll Forming Machine. Our Steel Roll Forming Machine is designed to meet the needs of merchants in countries outside of China who are looking for high-quality machines that can produce steel sections with precision and speed.

Our Steel Roll Forming Machine is designed and manufactured by our team of experts who are dedicated to providing the best quality products to our customers. We use only the best quality materials and state-of-the-art technology to ensure that our machines are capable of producing consistent results every time.

Whether you are a merchant looking to expand your business or a manufacturer looking to maximize your production output, our Steel Roll Forming Machine is the perfect solution for all your needs. With its advanced features and superior performance, our Steel Roll Forming Machine is sure to impress.

Features:

Our Steel Roll Forming Machine boasts a wide range of advanced features that make it one of the best machines available on the market today. Some of the most notable features of our Steel Roll Forming Machine include:

1. High-Quality Materials: Our machines are manufactured using only the best quality materials, ensuring that they are durable and long-lasting.

2. Easy-to-Use Control System: Our Steel Roll Forming Machine comes equipped with an easy-to-use control system that makes it easy for operators to operate the machine.

3. Precision Roll Forming: Our machines are designed to produce sections with precision, ensuring that every section produced is consistent in size and shape.

4. High Production Output: Our Steel Roll Forming Machine is capable of producing a large quantity of sections in a relatively short amount of time, maximizing your productivity.

5. Efficient and Energy Saving: Our machines are designed to be energy-efficient, reducing your energy costs and helping you save money in the long run.

Benefits:

Our Steel Roll Forming Machine offers many benefits to merchants looking to expand their business. Some of the most notable benefits of our Steel Roll Forming Machine include:

1. Increased Productivity: Our machines have a high production output which helps to increase productivity and reduce manufacturing time.

2. Consistency: Our Steel Roll Forming Machine produces sections with precision, ensuring that every section produced is consistent in size and shape.

3. Versatility: Our machines are capable of producing a wide variety of steel sections, making them an ideal solution for many different applications.

4. Highest Quality: Our machines are designed and manufactured to the highest quality standards, ensuring that they are durable and long-lasting.

5. Cost-Effective: Our Steel Roll Forming Machine is an affordable solution for merchants looking to expand their business, providing them with a cost-effective way to increase their productivity and profits.

Conclusion:

If you are a merchant looking for high-quality Steel Roll Forming Machine to expand your business, look no further than our product. Our Steel Roll Forming Machine offers a wide range of advanced features and benefits, making it one of the best machines available on the market today.

So why wait? Contact us today to learn more about our Steel Roll Forming Machine and how it can help you maximize your productivity and profits. We are confident that our machine will exceed your expectations and provide you with the competitive edge you need to succeed in today's market.

Introduction

This Steel Roll Forming Machine adopts a continuous metal forming process, which can bend or form various metal plates, strips or coils into a continuous cross section. It adopts compact structural design and consists of feeding device, punching system, roll forming system and other parts, with high strength and high processing efficiency. At the same time, this machine is equipped with quick change function, which can be used in combination with linear guide rail, so that it can easily and smoothly change the coil size for better production.

Features

This Steel Roll Forming Machine is equipped with standard accessories, and the components run smoothly, which can ensure better control of the contour shape of the final product. Its operation process is time-saving and labor-saving, which greatly improves the production efficiency and has the characteristics of simple operation and high precision, so it is very suitable for large-scale factories. In addition, its light steel frame design aims to provide greater flexibility and higher reliability, which is convenient for transportation in actual production to produce profiles with various thicknesses.

Technical Date

| Coil Material |

Coil |

Galvanised steel sheet or as per request |

|

Coil Thickness |

0.4-0.8mm or as per request |

|

|

Coil Width |

depend on profile |

|

|

Yield Strenth |

250-350Mpa |

|

|

Decoiler |

Decoiler Type |

Manual (standard) or hydraulic type |

|

Weight Capacity |

3T (standard), customized |

|

|

Main Roll Forming |

Forming Station |

12-18 stations, depend on profiles |

|

Roller Material |

High grade 45# steel, surface with hard chrome 0.05mm |

|

|

Shaft Material |

High grade 45# steel, quenched |

|

|

Shaft Diameter |

70mm |

|

|

Drive Type |

Chain transmission |

|

|

Forming Speed |

0-15m/min |

|

|

Main Power |

7.5KW |

|

|

Cutting Device |

Cutting Type |

Hydraulic cutting |

|

Cutting Die Material |

Cr12Mov steel, HRC58-62 |

|

|

Cutting Tolerance |

+/-1.5mm |

|

|

Electrical System |

PLC Brand |

PANASONIC brand |

|

Inverter Brand |

YASKAWA brand |

|

|

Encoder |

OMRON brand |

|

|

Touch Screen |

MCGS brand |

|

|

Hydraulic System |

Hydraulic Station |

Famous Chinese Brand |

|

Hydraulic Power |

4KW |

|

|

Runout Table |

Table Type |

Simple non power type table |

|

Function of Table |

To support the profile sheets after cutting |

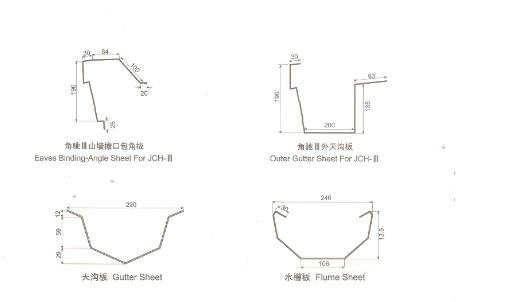

Profile Drawing

Process Drawing

Why choose us?

- Our products are both easy to use and maintain, saving our customers time and money.

- While we are based in the domestic market, the company is actively exploring overseas markets to achieve accelerated growth of a global integrated marketing network.

- We are driven by a commitment to excellence in everything we do.

- We adhere to the customer-centric, improve service quality, standardize service behavior, and provide value-added services.

- We are constantly exploring new and innovative ways to improve our products and services.

- We uphold excellent, professional, service as the core values of the enterprise.

- We are a Chinese factory that specializes in providing high-quality Cold Roll Forming Machines and professional services.

- Our company's mission is to wholeheartedly produce the best, distinctive, market-oriented and competitive Steel Roll Forming Machine.

- We take great care in every step of the manufacturing process to ensure the highest quality products.

- We will continue to unite as one, fully promote the implementation of a new round of strategic planning, and achieve leapfrog development.

Hot Tags: steel roll forming machine, Steel Decking Sheet Roll Forming Machine, Double Layer Roll Forming Machine, Rollfomer, Cold Roll Forming, Corrugated Steel Sheet Rollformer, Door Frame Roll Forming Machine