Sheet Metal Forming Machines

Description

Introduction

As a manufacturer located in China, we are proud to introduce our latest product, Sheet Metal Forming Machines. Our machines are designed to help you save time and money in your sheet metal forming process. If you're looking for high-quality machinery that can handle your sheet metal forming needs, our product is the answer. In this article, we will introduce you to the key features of our Sheet Metal Forming Machines, which make them a must-have for any merchant looking to streamline their manufacturing process.

Quality Materials

At our company, we understand that the quality of the materials used in the manufacturing process is critical to the overall quality of the finished product. That's why we use only the highest-quality materials in our machines. Our Sheet Metal Forming Machines are made of high-grade steel, which ensures they have excellent durability and long-lasting performance.

Versatility

Our Sheet Metal Forming Machines are highly versatile and can be used for a wide range of applications. They can be used to form flat sheets of metal into a variety of shapes, including boxes, channels, and curves. The versatility of our machines means that they can be used by a wide range of industries, including automotive, construction, and electronics.

Ease of Use

We understand that ease of use is an essential factor when it comes to machinery. That's why we have designed our Sheet Metal Forming Machines to be simple and straightforward to use. With our machines, you won't need to spend hours learning new software or complicated controls. The controls are user-friendly and easy to understand, making it easy for anyone to use the machine.

Efficient Production

Our Sheet Metal Forming Machines are designed to help you streamline your production process. They are automated, which means that they can work continuously, and you won't need to pause production to make manual adjustments. This efficiency means that you'll be able to produce more in less time, saving you money in the long run.

Customizable

We understand that every business has different needs, and that's why our Sheet Metal Forming Machines are customizable. We can help you choose the right machine and customize it to fit the unique needs of your production process. With our machines, you can tailor the capabilities to your specific needs, making them more efficient and productive.

Affordability

We believe that high-quality machinery should be affordable for all businesses, which is why we offer our Sheet Metal Forming Machines at an affordable price. We strive to keep our prices competitive while maintaining the highest standards of quality.

Conclusion

Our Sheet Metal Forming Machines are a must-have for any manufacturer looking to streamline their production process. With features such as high-quality materials, versatility, ease of use, efficient production, customizability, and affordability, our machines are the perfect choice for any merchant. For more information on our Sheet Metal Forming Machines, please contact us today.

Introduction

Metal sheets can be used in all aspects of the construction industry, and Sheet Metal Forming Machines are used to produce these sheets. This machine can produce thin plates of different sizes and thicknesses, and the specifications of each batch of thin plates can be highly unified. The production efficiency of this machine is very high, thus significantly reducing project time. High automation operations reduce manual labor, not only improving production efficiency but also saving a significant amount of costs. We have been engaged in this industry for many years, so we have rich experience in product research and development, sales, and other aspects. We will provide the highest quality service to every customer.

Features

1. Sheet Metal Forming Machines can produce efficiently and has very high accuracy, making it a cost-effective machine.

2. The products produced by this machine have few defects, high quality, and high uniformity, so they are loved by a large number of customers.

3. This machine can produce efficiently and has very high accuracy, making it a cost-effective machine.

4. High degree of automation reduces the likelihood of manual intervention and operational errors.

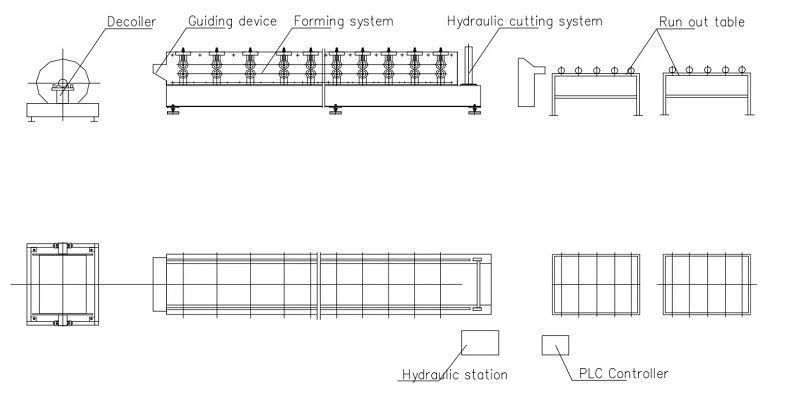

Rollforming process: uncoiler, forming, forming step effect, cut to length.

Fully Automatic Control System with PLC.

Easy operation: Key in the length and quantity on the control panel.

One year warranty.

We also can do a custom roll forming machine, We can design the machine according to your specification and profile drawing.

One roll forming machine only can produce one profile.

|

Raw material |

Galvanized steel or PPGI |

|

Thickness |

0.3-1mm |

|

Roller stations |

13 or depend on customer' drawing |

|

Shaft diameter |

75mm |

|

Solid shaft material |

High grade 45# steel with Cr12 mov coated, quenching & tempering & treatment |

|

Roller material hardness 30-40 HRC |

Cr12 |

|

Machine size |

About 6*1.5*1.3 m |

|

Production speed |

8-20 m/min |

|

Cutting tolerance |

± 1mm |

|

Cutter material |

Cr12 |

|

Cutting operate |

Hydraulic cutting |

|

Driving way |

Chain 1 inch |

|

Main forming power |

4kw |

|

Power for cutter |

3kw |

|

Voltage |

380V/50HZ, 3P or Customized as customer' request |

|

PLC brand |

Delta made in Taiwan |

|

Screen |

Touchable screen |

Why choose us?

- We offer a wide range of Cold Roll Forming Machines to suit a variety of needs.

- Our company focuses on providing all kinds of advanced Sheet Metal Forming Machines for the market and strives to achieve industrial transformation. We will always adhere to the development concept of "innovation" and provide more high-quality products and services for enterprises and units.

- Our products are designed to be easy to use and maintain.

- Our company always adhere to the spirit of craftsmen to create every Sheet Metal Forming Machines and constantly improve the quality and service.

- Our products are of the highest quality and are offered at competitive prices.

- We are committed to enhancing our core competitiveness and effectively responding to changes in the new market situation and environment.

- We are invested in the success of our customers and are dedicated to providing them with the best possible products and services.

- We strive to achieve professional and regional leadership, and continuously create new value for our shareholders, customers and employees.

- Our company is dedicated to providing the best possible value to our customers.

- The company always pays attention to quality first, integrity management, pays attention to Shuang Lei, and upholds the business tenet of customer first.

Hot Tags: sheet metal forming machines, Sheet Making Machine, Sheeting Roll Forming Machine, Steel Frame Rollformer, C Section Rollformer, CZ Purlin Roll Forming Machine, Beam Roll Forming Machine