Roller Shutter Forming Machine

Description

Introduction:

Are you looking for a reliable and efficient way to manufacture roller shutters for your business? Look no further as we bring you our Roller Shutter Forming Machine designed specifically for the purpose of producing quality roller shutters for you.

Our machine is made of high-quality materials and is designed by expert engineers with years of experience in the industry. It is a fully automatic and advanced machine that offers advanced features such as speed control, precision cutting and an easy-to-use control panel, making it a perfect solution for small to big businesses.

Features:

Our Roller Shutter Forming Machine boasts of several features that set it apart from its competitors.

1. Fully Automatic:

The machine is fully automatic, which means it operates with minimal intervention from the user. It is a plug and play machine, which means it is easy to set up and use.

2. Easy to Use Control Panel:

The control panel of our machine is designed to be easy to use by anyone. The control panel is straightforward and user-friendly. The operator can easily control the machine, set parameters such as speed and cutting specifications to optimize the end product.

3. Precision Cutting:

The machine uses high-quality blades for precise cuts, ensuring that the roller shutter's dimensions are accurate and consistent in every order. Precise cuts also reduce the chance of waste material and improve the efficiency of the manufacturing process.

4. Speed Control:

The machine's speed can be easily controlled, which means production can be adjusted depending on the given order quantity. This feature makes our machine ideal for small-scale production as well as large-scale production.

5. Durability:

The machine is made of high-quality materials, which makes it durable and long-lasting. It can withstand frequent use, and the regular wear and tear of the manufacturing process.

Benefits:

Our Roller Shutter Forming Machine offers several benefits to you as a merchant.

1. Reduced Manufacturing Costs:

The machine's automated features reduce the need for manual labor, which translates to reduced labor costs. The machine's precision cutting also reduces waste material, resulting in cost savings.

2. Faster Turnaround Time:

The machine's speed and precision cuts reduce the production time, resulting in faster turnaround time for you. The fast turnaround time means you can fulfill customer orders quickly and efficiently, which can lead to increased customer satisfaction and repeat business.

3. Consistent Quality:

The machine's precision cutting ensures that the dimensions of the roller shutters are consistent, which means the quality of every order is constant. Consistent quality also means satisfied customers and repeat business.

4. High Return on Investment:

Investing in our Roller Shutter Forming Machine provides you with a high return on investment. The labor cost savings, reduced waste material, and faster turnaround time result in increased profits for your business.

Conclusion:

In conclusion, our Roller Shutter Forming Machine is an efficient, reliable, and cost-effective solution for producing high-quality roller shutters. With its fully automated features, precision cutting, and user-friendly control panel, the machine can help your business increase productivity, reduce manufacturing costs and realize high-quality standards results.

Invest in our Roller Shutter Forming Machine today and experience the benefits of increased profits, improved customer satisfaction, consistent quality, and high return on investment.

Introduction

This Roller Shutter Forming Machine is used for producing roller shutter doors, which are widely used in various industries, buildings, and warehouses. This machine has extremely high production efficiency and high production accuracy. A high degree of automation reduces manual labor, thereby reducing errors caused by manual labor and also reducing labor costs. The machine runs stably and will not get stuck or shake violently. Various parameters can be adjusted, so this machine can produce roller shutter doors of different sizes. We always prioritize our customers, so you can make various requests or inquiries from us.

Features

1. We accept customization, and you can provide us with drawings or requirements for our production and processing.

2. This machine can produce efficiently and has very high accuracy, making it a cost-effective machine.

3. High automation to achieve low error, high precision, and high efficiency, while reducing labor costs.

4. The outer surface of this Roller Shutter Forming Machine is firm, with good corrosion resistance and waterproofing.

Technical Information

|

Configurations |

Decoiler, Guiding Platform, Main Machine of Roll Forming, Cutting Device, Output table, Electric Motor, Hydraulic Station, PLC Control |

|

Processing Material |

Aluminium, PPGI, GI Sheet/Coil (Q235 & G550) |

|

Material Thickness |

0.3---0.9mm |

|

Feeding Width |

As per drawing |

|

Effective Width |

As per drawing |

|

Roller Station |

12-16 stations |

|

Roller Material |

45# steel with surface chrome 0.03-0.05mm, Hard chrome mirror polishing, heat treatment to 58-62℃, tooled by grinding machine for two times to ensure the precision of final product. |

|

Shaft diameter |

50-60mm, solid |

|

Shaft Material |

45# carbosn wrought steel, forged, tooled by grinding machine for two times to ensure the precision of final product. |

|

Wall Panel |

Thickness: 16mm or Hard column |

|

Main Motor Power |

4kw+3kw |

|

Production Speed |

12-15m/min |

|

Control System |

PLC computer control PLC brand: Panasonic from Japan |

|

Cutter Material |

Cr12mov with quenched treatment |

|

Voltage |

380V, 50Hz, 3 phrases or as required |

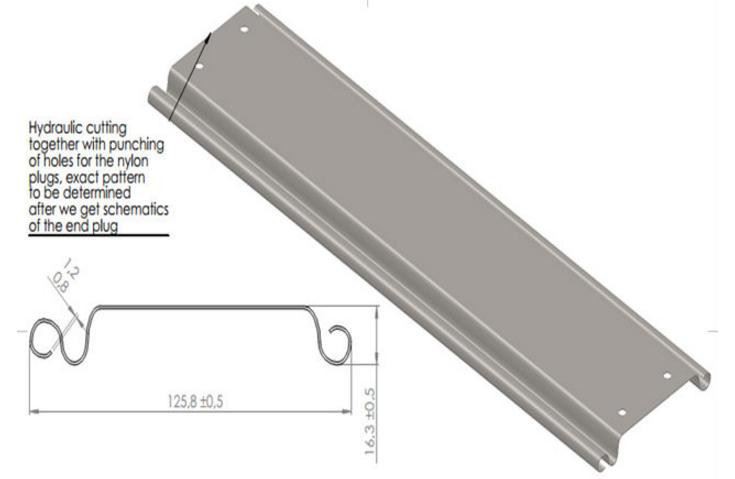

Profile Drawing

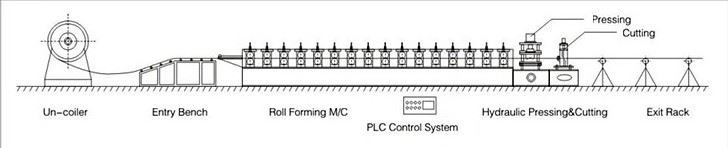

Layout

Why choose us?

- Our products are designed to meet the highest standards of quality and safety.

- We are rooted in the field of Roller Shutter Forming Machine we love, pay attention to the business philosophy of benign sustainable development, build a professional sales team and technical team to serve customers.

- We believe that our products are the best in the industry and our customers agree.

- We believe in teamwork, personal professional development and open and efficient communication.

- Our company is committed to providing exceptional value to our customers.

- We implement professional management and intensive operation, and establish a humanistic talent support team.

- We are constantly innovating and improving our products to meet the changing needs of our customers.

- In terms of supply quality, export process and technical support, we can provide professional services for customers.

- We are committed to working collaboratively with our customers to ensure their success.

- We have perfect testing methods, advanced production technology and accurate control of material properties.

Hot Tags: roller shutter forming machine, Cold Roll Former, Purlin Roll Forming Machine, C Purlin Rollformer, Roll Forming Machine, Steel Frame Rollformer, Metal Roofing Roll Former