Steel Water Tank Rollformer

Description

Introduction

The Steel Water Tank Rollformer is a unique and innovative product that has been designed to help people achieve their water storage goals. It’s a state-of-the-art water tank manufacturing machine that’s well-suited to producing custom-made water tanks based on your specific requirements. It’s designed to cater to both large-scale and small-scale water storage solutions, making it ideal for homeowners, business owners, and industrialists alike.

Features & Benefits

The Steel Water Tank Rollformer provides an array of features and benefits that make it stand out from other rollformer machines in the market. Some of the features and benefits include:

1. High Quality

One of the key attractions of the Steel Water Tank Rollformer is its manufacturing quality. The machine is made with high-quality materials that provide the perfect fit for water tank production. Not only does the machine provide precision and accuracy in creating tanks that are free from defects, but its high-strength material also ensures durability and longevity.

2. Easy to Use

Another feature that buyers will appreciate is the user-friendly nature of the Steel Water Tank Rollformer. Set up is simple and straightforward, allowing merchants to begin using the machine as soon as possible. There is also no need to hire additional laborers to operate the machine, meaning that you can save on labor costs when using the steel water tank rollforming process.

3. Low maintenance

The machine’s low maintenance requirements is another benefit that merchants will appreciate. The Steel Water Tank Rollformer has been designed with a low-impact motor system that’s sturdy enough to last for years to come with regular servicing, while the engineering makes disassembling and reassembling the machine for maintenance extremely easy.

4. Precision and Accuracy

The machine provides precision and accuracy in making roll formed steel water tanks that are structurally sound, watertight, and free of defects. Merchants can expect to see more than 99.9% accuracy in the resultant product.

5. Customization

Customization is another significant benefit of the Steel Water Tank Rollformer. It is ideal for tailoring water tanks to meet specific individual needs. It can make tanks of various sizes and shapes, so merchants can offer customers a variety of options to choose from.

Technical Specification

The Steel Water Tank Rollformer has specific technical specifications that make it a unique machine. It has a maximum speed of 15m/min and can handle steel thickness ranging from 0.4 – 1.5mm. It has a total power of 19KW and a line dimension of 16m x 2m x 1.8m. The device's weight is approximately 14 tonnes, so merchants will need to consider having a suitable space to accommodate the machine.

Conclusion

The Steel Water Tank Rollformer is a must for anyone looking to produce water storage tanks efficiently and cost-effectively. Its high-quality production, low maintenance, customization, technical specification, and ease of use make it the perfect choice for merchants looking to produce water tanks that cater to both individual and commercial distribution. With this machine, merchants are sure to produce top-grade water tanks that meet customers' diverse needs.

As a trusted manufacturer in China, we guarantee that our Steel Water Tank Rollformer will meet and exceed your expectations. It's an investment that will result in quality products and satisfied customers. Get in touch with us to get your hands on this innovative and game-changing product.

Introduction:

Steel Water Tank Rollformer is used to produce steel water tanks of various sizes and capacities. By using the rolling forming process, the steel plate can be bent into a spiral shape to facilitate subsequent welding. The steel water tank produced by this machine is very durable and has received high praise from many customers. This machine has a high degree of automation and can quickly complete operations such as rolling and forming. The internal parts are of high quality, so the machine requires less maintenance. This machine can produce water tanks of different models and sizes. Our company also accepts customer customization requirements and produces and processes according to the drawings and specifications provided by the customer! Welcome to contact us for more information!

Features

1. This machine is used to produce steel water tanks of different sizes and capacities, and has high production efficiency and accuracy.

2. The water tanks produced by this Steel Water Tank Rollformer are durable, seamless, and corrosion-resistant.

3. We accept customization, and you can provide us with drawings or requirements for our production and processing.

4. Adopting automated rolling and other operations to improve production accuracy and efficiency.

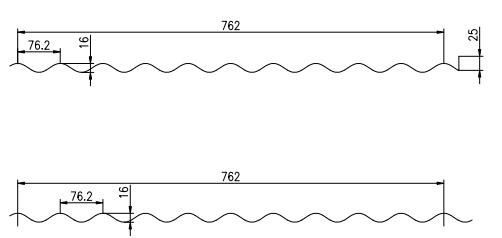

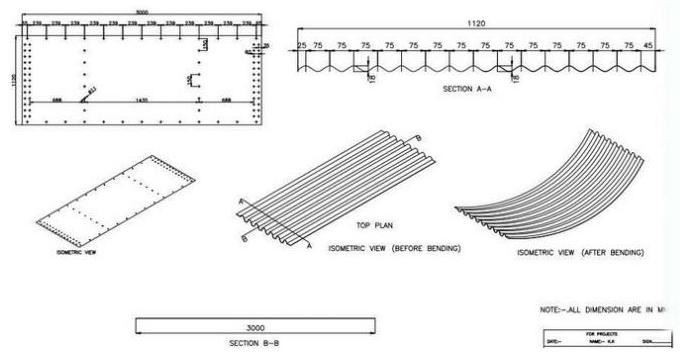

1. Profile Drawing

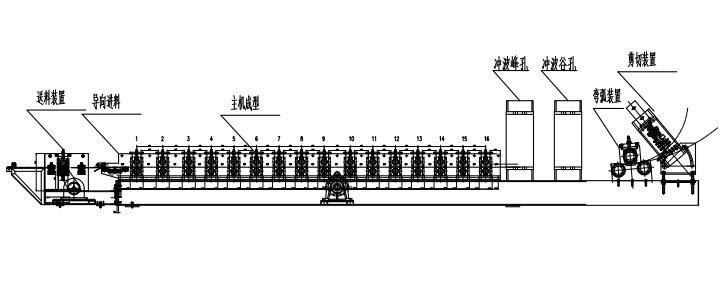

2. Process Drawing

Detail Information

10T Passive decoiler | |

Steel coil width | From 900 mm to 1250 mm |

Internal diameter of coil | Variable, from 470 mm to 620 mm |

Maximal out diameter | 1600mm |

Maximum coil weight | 10000 Kg |

Pulling of steel from the coil to the pulling mechanism for the start | Manual |

Suitable of the pulling mechanism for all required thicknesses | Iincluded |

Device preventing unwinding of the coil from the coil holder | Included |

Feeding | |

Feeding type | Adjustable |

Feeding width range | 980-1200mm |

Entrance and guide roller | Diameter is ¢65mm, material is SAE1045, HRC48-52° surface with chrome |

Roll Forming | |

Material of the profile | 195-235Mpa GI or carbon steel |

Thickness range | 1mm |

Maximum production speed | Not less than 13 meters per minute (for non-perforated profiles, excluding cutting) |

Main motor power | 18.5kw, AC motor, motor inside of main machine (Brand: Guomao of China) |

Machine Voltage, Frequency, Phase | 380 V, 50 Hz, 3Phase |

Roll station | 20 stations |

Roller material | Gcr15 bearing material chrome plated surface with hardness 58-62 degree, CNC |

Shaft diameter | ¢65mm material: SAE1045 with quenching and tempering |

Transmission | By chain |

Color of machine | Blue and yellow (or base on customer request) |

Punching | |

The punches and dollies will be CR12, hardness HRC 58-62 and chrome coating both punches and dolies should be easily replaceable without requiring disassembly of complete units. | |

Hydraulic power | 5.5kw |

Working pressure | 12-16Mpa |

Cutting system | |

Cutting motion | The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start. |

Cutting after forming | Cut the sheet after roll forming to required length |

Material of blade | CR12with heat treatment |

Length measuring | Automatic length measuring |

Tolerance of length | +/- 2mm |

3 Station Curving Machine | |

Thickness | 1mm |

Maximal feeding width | 1250mm |

Roll speed | 0—10m/min |

Main power | 3KW |

Roll station | 3 stations |

Shaft material | 45# forge steel, polished and coated with chrome |

Diameter of shaft | 180mm |

Material of roller | Gcr15 steel, polished and with HRC58-62° |

Adjust angle motor power | 3KW |

Curving mode | Horizontal |

Curving diameter | ≥800mm |

Control desk | |

Programmable setting of profile dimensions | To be provided |

Setting of distances between the perforation holes in the transversal direction of the profile | To be provided, according to the approved drawing |

Operating system language | English and Russian. |

Voltage, Frequency, Phase | 380 V, 50 Hz, 3Phase |

Control panel | Button-type switch and touch screen |

Unit of length | Millimeter (switched on the control panel) |

PLC brand | Panasonic |

Frequency converter brand | Yaskawa |

Touch screen | Taiwan Weinview |

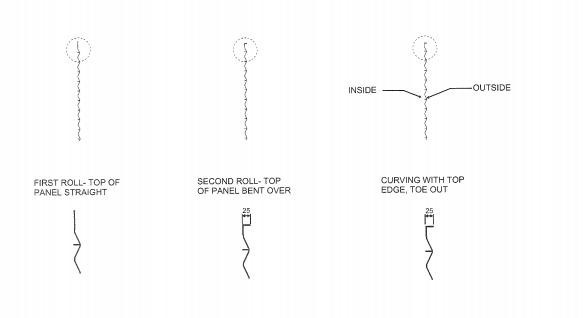

Lip Drawing

Water Tank Pictures

Why choose us?

- We're a trusted supplier of high-quality Metal Roll Former products to customers around the world.

- Since its establishment, our company has always adhered to the belief that quality and customer interests are paramount, and high-quality Steel Water Tank Rollformer at competitive prices is our pillars of life.

- We're committed to continuously improving our Metal Roll Former products and services to meet the changing needs of our customers.

- The management policy of our company is the firm determination to achieve our goals and the perseverance to be ethical at all times.

- Our Metal Roll Former products are some of the best on the market, and we stand by their quality.

- Our enterprise style is to do our duty, efficient and fast, and coordinate and standardize.

- We're committed to providing our customers with exceptional Metal Roll Former products and service.

- We have always adhered to the principle of market first and customer first. From the selection of raw materials, production to shipment, we implement strict control to ensure first-class product quality.

- We're committed to providing our customers with Metal Roll Former products that exceed their expectations in terms of quality and performance.

- We never consider how to cope with and overwhelm the competitors, but focus on how to lead all the competitors in terms of product quality.

Hot Tags: steel water tank rollformer, Corrugated Forming Machine, Beam Purlin Roll Forming Machine, Highway Guardrail Machine, Shutter Door Roll Forming Machine, Glazed Tile Roof Sheet Roll Forming Machine, Steel Silo Roll Forming Machine