Steel Silo Rollformer

Description

Introducing the Steel Silo Rollformer - Your Solution for High-Quality Silos

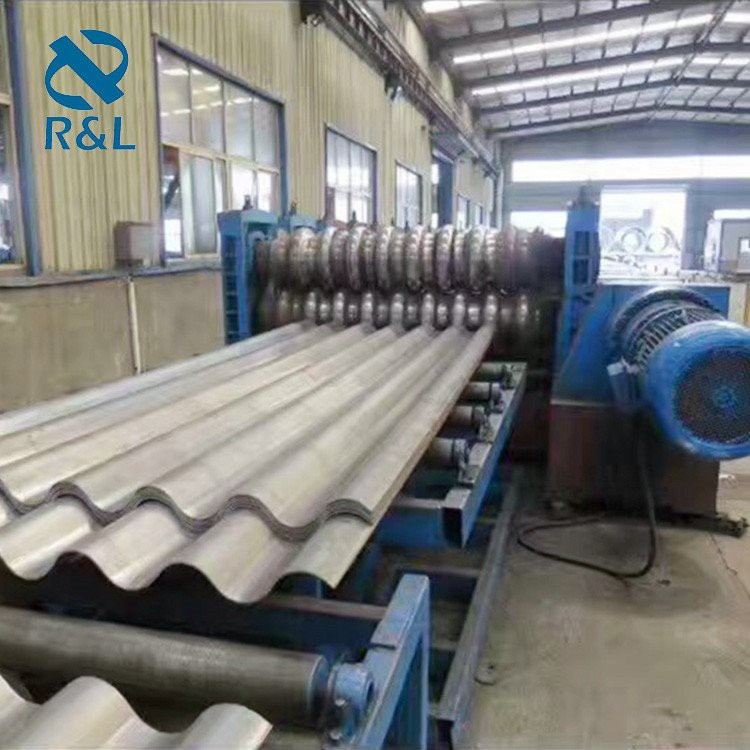

As a leading manufacturer in China, we take pride in offering innovative and high-quality products for our customers. Our Steel Silo Rollformer is one such product that has been designed to meet the needs of merchants looking to build storage silos that are strong, durable and cost-effective.

Steel Silos are an essential part of the storage and handling of raw materials such as grains, seeds, and animal feed. They are preferred over traditional concrete silos due to their flexibility, increased storage capacity, and reduced maintenance costs. Moreover, steel silos can be built faster, which is always an advantage in the fast-moving world of business.

Our Steel Silo Rollformer has been designed keeping in mind the various advantages that steel silos offer over traditional ones. The rollformer is a high-productivity machine that uses continuous rolling technology to produce ultra-strong and durable sheets of steel. These sheets are then formed into the shapes required for the silos.

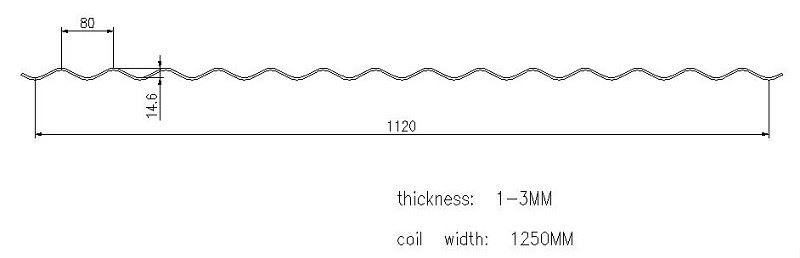

The Steel Silo Rollformer is suitable for producing steel sheets of various thicknesses and widths, making it a versatile machine that can be used for different types of silos. The rollformer can produce sheets up to 3 mm thick with a width of 1250 mm, making it possible to manufacture steel silos with capacities ranging from 50 to 30,000 tons.

Our Steel Silo Rollformer uses high-quality materials and components to ensure that the machine performs at its best. The machine has a robust frame made from high-strength steel, and the rollers are made from high-carbon chrome alloy steel. The rollers are precision-engineered to ensure smooth and efficient operation, and the machine has a user-friendly control panel that allows for easy adjustment of settings.

In addition to its high productivity and quality, our Steel Silo Rollformer is also energy-efficient, reducing your energy costs and making it an environmentally-friendly option. The machine also has a low maintenance requirement, which means that you can save on maintenance costs and downtime.

One of the main advantages of our Steel Silo Rollformer is its ability to produce sheets of different lengths. This feature is particularly useful for merchants who need to build silos of different sizes to meet the needs of their customers. The rollformer is also easy to operate, with minimal training required to get started. This means that you can begin producing steel sheets for your silos quickly and easily.

At our company, we believe in delivering the best value for money to our customers, and our Steel Silo Rollformer is no exception. The machine is competitively priced and backed by our commitment to quality and service.

In conclusion, if you are looking to build high-quality steel silos that are strong, durable, and cost-effective, our Steel Silo Rollformer is the perfect solution. With its high productivity, versatility, and energy efficiency, it is a wise investment for merchants looking to grow their business and offer their customers the best quality silos.

Introduction

This Steel Silo Rollformer is widely used for producing various steel silos. We purchase the main components from a well-known company in China to ensure the performance of the equipment. We can also customize and design according to your specifications and exterior drawings. The products produced by this machine have few defects, high quality, and high uniformity, so they are loved by a large number of customers. This machine is equivalent to a production line, therefore it has diverse functions and produces steel silos with diverse specifications. The reasonable coordination between various components enhances the production effect. We have decades of production experience and can provide you with the best pre-sales and after-sales service.

Features

1. High automation operating procedures greatly reduce the required labor costs and make operations simpler.

2. The entire appearance is very sturdy, which can counteract the vibrations generated during production, thereby extending the product's service life.

3. This Steel Silo Rollformer has the characteristics of high efficiency and durability, which can minimize material waste and downtime.

4. The outer surface of this product is firm, with good corrosion resistance and waterproofing.

A. Profile

The profile is up to your request.

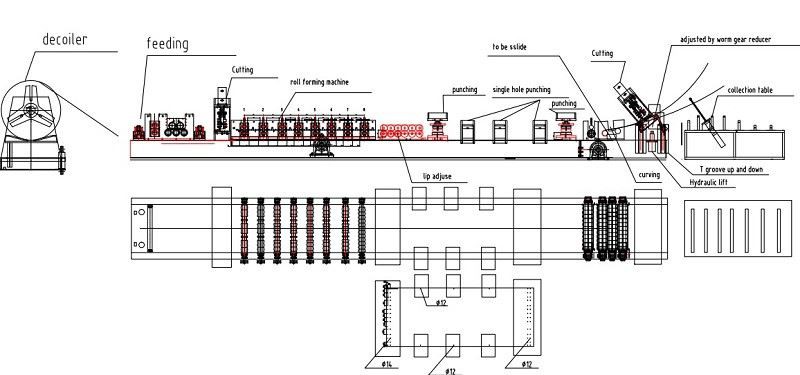

B. Technical Process/Sketch

Decoiler → guide & feed → leveling → roll forming → punching → curving → cutting → collection

C. Basic parameters of finished product

1. Thickness of panel: 1-4mm hot-dip zinc-coated steel

2. Mechanical performance: yield strength 340MPa, tensile strength 470MPa

3. Coil width: as per customer request.

4. Inner diameter of coil: φ460-550mm

5. The width of finished profile width after formed: (As per required)

D. Main information

1. The construction of roll-former: wall frame.

2. Transmission way: motor-chain drive-chain -main shaft

3. Roll-forming station: 18 stations

4. Main power: 15KW 415V 50HZ 3-phase Brake Motor

5. Main reducer: Cycloidal Pinwheel Reduction Box: 33-43-15KW.

6. Material of rollers: qualified 45# steel, galvanization treatment, to increase the smooth of roller surface and make sure of its service time and also avoid surface damage of the sheet.

7. The shape of rollers is designed through German design software COPRA, and processed on the precision NC machine. The surface of rollers is polished

8. The diameter of shaft for rollers: φ85, 45# steel quenched and tempered.

Why choose us?

- Our Metal Roll Former products are backed by a strong guarantee of customer satisfaction.

- We carry out characteristic and professional operations, implement standardized enterprise management, and implement personalized and high-quality services.

- Our Metal Roll Former products are made to withstand even the most demanding applications and environments.

- Relying on our strong R&D and technical strength, our main products are in the leading position in the same Steel Silo Rollformer industry in recent years, and the main performance indexes of some products have reached the international advanced level.

- Our Metal Roll Former products are made from the finest materials and with expert craftsmanship.

- Facing the future, Tianxiang will enter the stage of transformation and development, aiming to become the most valuable Steel Silo Rollformer product and solution provider in the Steel Silo Rollformer field in China.

- We're proud of our reputation for providing high-quality Metal Roll Former products to our customers.

- We provide a full range of resource support for our employees to help them grow and promote the continuous development of the company.

- We believe in providing our customers with exceptional value and high-quality Metal Roll Former products.

- Our company encourages the progress of research and development personnel, so that their academic and technical achievements are highly recognized within the group.

Hot Tags: steel silo rollformer, Metal Roll Forming Machine, Double Layer Roll Forming Machine, Steel Decking Sheet Roll Forming Machine, HIgh Speed Purlin Roll Forming Machine, Iron Roof Tile Making Machine, Metal Tile Sheet Making Machine