Z Purlin Forming Machine

Description

Introducing The Z Purlin Forming Machine: The Ultimate Solution for Efficient and Effective Building Construction

As a manufacturer located in China, we are proud to offer an exceptional product that is practical, efficient and of the highest quality. The Z Purlin Forming Machine is one of our prestigious products that continues to leave an indelible mark in the construction industry, globally. In this product introduction, we will provide comprehensive details about this highly sought after product and its advantages in the building industry for merchants outside of China.

Overview of the Z Purlin Forming Machine

The Z Purlin Forming Machine is a highly advanced and versatile piece of equipment that is used to manufacture Z purlins used in the building industry. Essentially, a Z purlin is a horizontal structural steel member that is widely used in various construction applications, such as building frames, roofing, and sheeting, as well as wall cladding. The machine features a pneumatic system and computer control technology that can produce Z purlins with varying thicknesses (up to 3mm) and widths (up to 430mm).

Advantages of the Z Purlin Forming Machine

The Z Purlin Forming Machine is an excellent investment for any merchant in the building industry, and for several reasons. Here are some of the advantages of obtaining this product for your business:

1. Efficient and Cost-effective

The Z Purlin Forming Machine is a highly efficient and cost-effective piece of equipment. This machine can produce high-quality purlins in large quantities, in a relatively short period, which reduces the overall production time and costs. Our machinery is designed to provide a rapid return on investment for all merchants in the building industry.

2. High Quality and Durability

Our Z Purlin Forming Machine is created using only the best materials for durability, and to ensure that it delivers the highest quality products for our customers. Additionally, the machine is designed with high-quality hydraulic and pneumatic systems that ensure optimum performance for years to come.

3. Versatile Design Capabilities

The Z Purlin Forming Machine is a highly versatile piece of machinery that can be used in the production of Z purlins to meet various design specifications. The machine can manufacture purlins of any length and size, allowing merchants to customize their products according to their specific customer needs.

4. User-friendly and Safe

Our Z Purlin Forming Machine is designed to be user-friendly and safe with an easy-to-use interface. It comes with a safety guard and features provide operators with complete control over the manufacturing process. Additionally, the machine is energy-efficient, reducing environmental impact, and minimizing operating costs.

5. Technical Support

As a manufacturer, we understand the value of high-quality technical support for our clients. We offer professional and reliable technical support to ensure that our clients operate the Z Purlin Forming Machine at optimal efficiency.

Conclusion

In conclusion, the Z Purlin Forming Machine is a highly efficient, versatile, and cost-effective product for any merchant in the building industry. With its ability to produce high-quality Z purlins with varying thicknesses and widths, the machine is an excellent investment for those striving for efficiency and precision. We are committed to helping our customers better their businesses and operations with our state-of-the-art machinery, and we look forward to hearing from you soon. Contact us today for your orders or for more information about our products and services.

Introduction

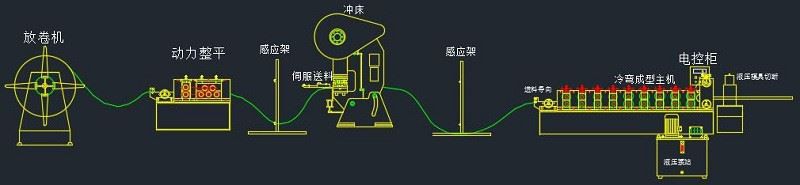

Z Purlin Forming Machine can actually be seen as a fully automated production line. Adopting fully automatic operation, data such as sheet length, stamping position, quantity, etc. can be set, so this product can produce various specifications of Z-shaped steel purlins. In terms of operation, due to the addition of PLC and automation programs, the operation is very simple and time-saving. The entire production line includes uncoilers, electric leveling machines, servo feeders, punches, rolling forming, hydraulic sizing, PLC control systems, hydraulic systems, and collection platforms. If you are interested in this product, please feel free to consult us at any time.

Features

1.The high degree of automation reduces the possible errors caused by manual participation, while also saving labor costs.

2. Multiple devices operate together to quickly produce Z-shaped steel purlins in a reasonable sequence.

3. The entire appearance is very sturdy, which can counteract the vibrations generated during production, thereby extending the product's service life.

4. One Z Purlin Forming Machine is equivalent to a production line and can be used continuously for many years, so its cost-effectiveness is very high.

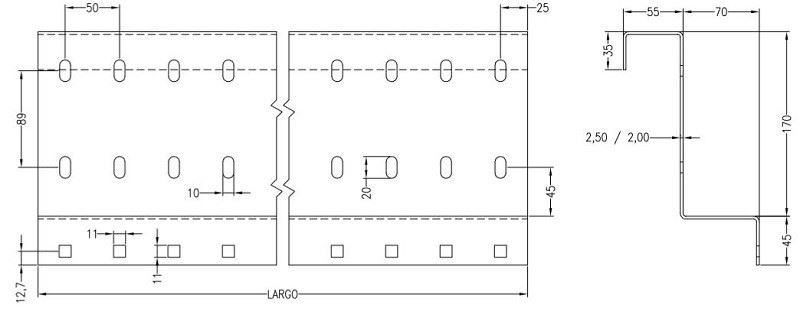

1. Profile Drawing

2. Process

3. Main Parts

Decoiler, leveler, servo feeder, quick puncher, roll forming, hydraulic cutting, collection table, hydraulic system, PLC control system and so on.

3.1 Internal bracing decoiler

I. Coil inner: about ø550±50mm, Coil OD: about 1800mm

II. Coil Width: ≤500mm (MAX)

III. Loading Weight: 5T

3.2 Motor Leveler

I. Qty: seven rollers (do not includes one set of pinch roll)

II. Leveling roller diameter: Φ60mm

III. Effective Width: 500mm

IV. Speed max: 15m/min

3.3 Servo Feeder & Quick Puncher

I. Servo feeder power: 4KW

II.Brand: Siemens

III. Punching die material: Cr12MOV, quenching hardness 60-62 degree

IV. Quick puncher: 125T can be purchase by yourself.

3.4 Roll Forming

3.4.1 Transmission way: Reducer & chain

3.4.2 Frame: H steel welded with rib in the middle

3.4.3 Main power: 15KW (Siemens)

3.4.4 Reducer: K107 type, spiral bevel gear.

3.4.5 Forming station: 18

3.4.6 Forming speed: 6-8m/min

3.4.7 Thickness: 2.0-2.5mm

3.4.8 Roller material: GCr15, quenching (HRC58-62degree)

3.4.9 Bearing brand: HRB

3.4.10 Shaft Diameter: 7mm (40Gr material)

3.4.11 Wall frame thickness: 20mm

3.4.12 Chain type: 24A-1

Configure:

Converter: Siemens

PLC: Siemens

Detector: Panasonic

Low voltage: Schneider

Encoder: Omron

Why choose us?

- Our Profile Forming Machines are versatile, allowing you to manufacture a range of different profiles with one machine.

- We take the professional, differentiated and refined management approach, and we can become your most reliable long-term partner.

- Our Profile Forming Machines are not only superior in quality but also affordable.

- We adhere to high standards and strict requirements, guarantee the independence of quality supervision, and ensure that each Z Purlin Forming Machine meets quality requirements.

- We can also provide customized services for different types of Profile Forming Machines to meet specific needs.

- We believe that responsibility is the guarantee of quality, and quality is the life of an enterprise. Therefore, we start from the needs and satisfaction of our customers.

- When you choose our Profile Forming Machines, you can be sure of a long-lasting and reliable product.

- We follow the principle of "government-led, market-oriented operation" and strive to become a company with brand value and influence.

- Our Profile Forming Machines are manufactured using top-quality materials and advanced equipment.

- In the era of global fierce competition, design innovation is very important.

Hot Tags: z purlin forming machine, Floor Deck Roll Forming Machine, Sheeting Roll Forming Machine, Steel Roof Ridge Cap Roll Forming Machine, Rain Gutter Roll Forming Machine, Pallet Rack Roll Forming Machine, Downpipe Roll Former