C&Z Purlin Forming Machine

Description

Thank you for your interest in our C&Z Purlin Forming Machine. This high-quality machine is designed to meet the demands of modern construction sites and increase efficiency in the process of producing C&Z purlins. It is a versatile machine that can produce a wide range of purlin sizes with high precision.

Our C&Z Purlin Forming Machine is highly efficient and saves you time and labor costs. It is also cost-effective and easy to maintain. Our machine is designed with the latest technology and uses high-quality materials that ensure its durability and long-lasting performance.

One of the key features of our machine is its user-friendly operation. It is designed to be easy to use and it is suitable for both experienced and inexperienced operators. With our comprehensive user manual, our machine can be set up and operated in a short time, allowing you to start production immediately.

Another advantage of our C&Z Purlin Forming Machine is its high production speed. It can produce up to 45 meters of C&Z purlins per minute, which is a remarkable speed that increases productivity while reducing production costs. The machine also produces purlins with high precision, ensuring that your products meet the highest quality standards.

Our C&Z Purlin Forming Machine is also designed with safety in mind. We have incorporated several safety features to protect users and ensure safe operation. The machine is also designed to be energy-efficient and eco-friendly, reducing your energy bills while also being environmentally friendly.

With our machine, you can produce C&Z purlins of different sizes without the need for additional equipment. It is designed to be versatile and it can produce purlins with various lengths and thicknesses, giving you more options in your production processes.

In conclusion, our C&Z Purlin Forming Machine is the perfect investment for merchants looking to increase production efficiency and improve their bottom line. It is a versatile machine with high precision, speed, and safety features, which makes it an ideal choice for modern construction sites. We take pride in our quality and customer service, and we are confident that our machine will exceed your expectations. Contact us today to learn more about our C&Z Purlin Forming Machine and start saving time and money in your production processes.

Introduction

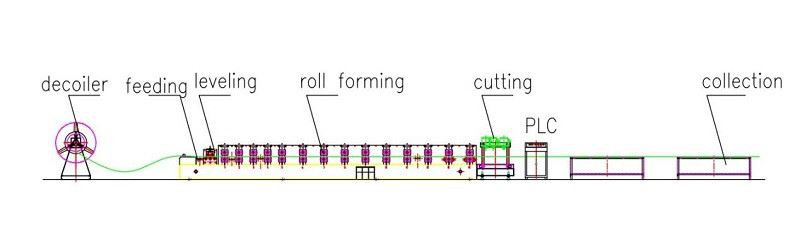

C&Z Purlin Forming Machine is used for manufacturing C-shaped and Z-shaped steel purlins. This product can produce purlins of different sizes and thicknesses for use in construction and manufacturing industries. High automation operating procedures greatly reduce the required labor costs and make operations simpler. Due to less manual intervention, the precision of production has also been improved. Equipped with a series of automatic devices such as fully automatic fixed length cutting and automatic punching, greatly improving work efficiency. Our company has been engaged in the production and research and development of C&Z purlin forming machines for many years. If you have special specifications, you can contact us to discuss customized production. If you need to provide drawings and detailed data, please contact us for more detailed information!

Features

1. C&Z Purlin Forming Machine is stable in operation, easy to operate, and has high production efficiency, bringing convenience to users while saving investment costs.

2. Different specifications of C-shaped and Z-shaped steel purlins can be produced to meet the needs of major steel mills.

3. High automation to achieve low error, high precision, and high efficiency, while reducing labor costs.

4. Multiple devices are closely and reasonably coordinated, capable of producing steel purlins with the fastest speed and highest accuracy.

|

Suitable raw material |

PPGI/ PPGL/ GI/ GL Steel Coils |

|

Thickness of coil sheet |

1-3mm |

|

Punching device |

Round hole or elliptical hole |

|

Effective width |

C: 80-300mm |

|

Under frame |

350 H-beam |

|

Diameter of shaft |

80mm, high grade 45# steel, finish turning, cylindrical grinding, with keyway |

|

Roller |

Gcr15, processed by CNC lathe, Quenched and tempered treatment, hard chrome coated 0.05-0.07mm |

|

Thickness of middle plate |

18mm |

|

Forming stations |

16 stations |

|

Drive type |

By chain (1.5 inch) link bearing model 6212 |

|

Power of main motor |

11kw with Cycloidal reducer |

|

Power of hydraulic statiOn |

5.5kw |

|

Forming speed |

About 15-20m/min |

|

Hydraulic cutting |

Controlled by PLC |

|

PLC |

DELTA, TAIWAN / Mitsubishi, Japan |

|

Material of cutting blade |

Cr12Mov, quenching 58-62ºC |

|

Frequency converter |

It has the advantage of slowing down before cutting, to ensure thelength accuracy (±1mm, far better than industrialstandard ±3mm). |

When we change from c purlin to z purlin, you only need direction of the rollers to be changed.

Specification:

Uncoiler bearing capacity: 5.0T

Roll forming system.

● Main motor type: three-phase motor

● Main motor power: 15KW

● Forming speed: 10-15m/min

● Roller material: GCr15

● 18 sets of rollers

● Spindle material: 40Cr

(Spindle is chrome-plated after grinding and heat treatment)

● Spindle diameter: 70mm

Hydraulic punching (post-roll forming)

● Punching method: hydraulic punching

● Punching material: SKD11

● Die: SKD11

● Cutting method: hydraulic cutting

● Hydraulic motor: 7.5KW

● Hydraulic pressure: 20MPa

PLC motion control system

● Automatic control of quantity and length of punching and cutting

● The machine should stop when cutting

Automatic length measurement and counting (accuracy +-2mm/+-1mm)

● Voltage: 415V, three-phase 50HZ

● PLC control board size (PLC: 700mm (L) × 1000mm (H) × 300mm (W))

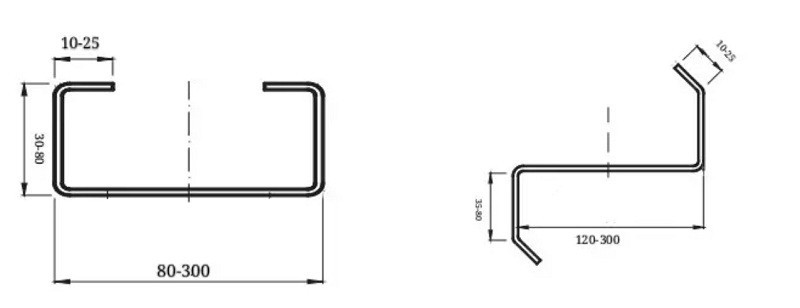

Profile Drawing

Profile Drawing

FAQ:

1. Q: What is your minimum order quantity, can you send me a sample?

Answer: Since our products are mechanical equipment, our minimum order quantity is 1 set, it is difficult to send you samples, however, we can send you product catalogs and warmly welcome you to visit our company.

2. Q: Is it possible to customize the machine as required, such as put our logo on it?

A: Of course our machines can be customized according to your needs, and your logo can also be affixed.

3. Q: How long is the delivery time of your machine?

Answer: Generally speaking, the delivery time of our machines is about 30 days, according to the requirements of customers, we will customize the machines according to customer requirements.

4. Q: May I know which payment your company accepts?

A: So far, we can offer 100% T/T before shipment, and 30% deposit paid by T/T, and the balance paid by L/C.

5. Q: Regarding after-sales service, how do you solve the problems encountered by overseas customers in a timely manner?

A: The warranty period of our machines is usually 12 months, during this period, we will arrange international express immediately to ensure the replacement parts as soon as possible.

Why choose us?

- We provide a range of options for payment and shipment for your convenience when buying our Profile Forming Machines.

- We believe that providing mature, efficient, simple and practical C&Z Purlin Forming Machine is the prerequisite for creating new value.

- Our company offers excellent quality Profile Forming Machines as well as top-notch customer service.

- We have been continuously optimizing product design and research and development for a long time to gradually improve the practicability of the company's products and the cost-effectiveness of environmentally friendly products.

- We offer professional installation and training services for our Profile Forming Machines, ensuring that you get the most out of your investment.

- The company's R&D employees have excellent products that have been applied to many markets and are respected and trusted by customers in different industries. We always adhere to the concept of keeping pace with customers, and constantly provide you with useful products.

- We offer a range of Profile Forming Machines with different processing capabilities, catering to different industries.

- We are a manufacturer of C&Z Purlin Forming Machine.

- Our Profile Forming Machines are designed to minimize raw material waste and maximize energy efficiency.

- In the future, our business layout, asset allocation and product design will all be centered on customer needs.

Hot Tags: c&z purlin forming machine, Cable Tray Roll Forming Machine, Downpipe Roll Former, Metal Sheet Making Machine, Shutter Door Roll Forming Machine, Shutter Door Forming Machine, Rolling Shutter Rollformer