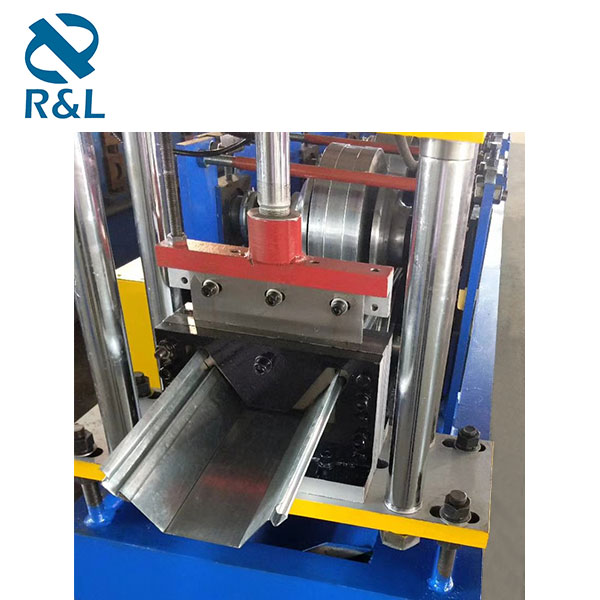

Gutter Forming Machine

Description

Introduction:

As a leading manufacturer of Gutter Forming Machine in China, we are proud to offer high-quality gutter forming machines to merchants around the world. Our machines are specially designed to meet the diverse needs of contractors, engineers, and builders in the construction industry.

Our Gutter Forming Machine is designed to be efficient, durable, and easy to use. It is made from high-quality materials that are designed to withstand wear and tear over time. At the same time, our machine is also equipped with the latest technology to ensure that it is always up to date with the latest advancements in the field.

Features:

The Gutter Forming Machine that we offer is equipped with many features that make it an ideal choice for merchants who are looking for a reliable and efficient gutter forming machine. Some of the key features of our Gutter Forming Machine include:

1. High-Quality Materials: Our machine is made from the best quality materials to ensure that it is durable, long-lasting, and can withstand the wear and tear of regular use.

2. Latest Technology: Our Gutter Forming Machine is equipped with the latest technology to ensure that it is always up to date with the latest advancements in the field.

3. Easy to Operate: Our machine is incredibly easy to operate, which makes it an ideal choice for contractors who want to get the job done quickly and efficiently.

4. Versatile: Our Gutter Forming Machine is versatile and can be used to produce gutters in a variety of shapes and sizes. This makes it ideal for a wide range of construction projects.

Benefits:

In addition to the features of our Gutter Forming Machine, there are also several benefits that merchants can enjoy when they purchase this machine. Some of the key benefits of our Gutter Forming Machine include:

1. High-Quality Output: The quality of the gutters produced by our machine is second to none. This means that merchants can offer their customers high-quality gutters that are sure to last.

2. Time-Saving: Our machine is incredibly efficient, which means that merchants can produce a large number of gutters in a relatively short amount of time. This helps them to complete their projects faster and more efficiently.

3. Easy to Operate: Our machine is designed to be easy to operate, which means that merchants do not need to have advanced technical skills to use it. This makes it an ideal choice for contractors who want to get the job done quickly and efficiently.

4. Low Maintenance: Our Gutter Forming Machine is designed to be low maintenance, which means that it requires minimal maintenance to keep it running smoothly.

Conclusion:

If you are a merchant looking for a reliable and versatile gutter forming machine, then our Gutter Forming Machine is the perfect choice for you. Our machine is designed to be efficient, durable, and easy to use, which makes it an ideal choice for contractors, engineers, and builders in the construction industry. Contact us today to learn more about our Gutter Forming Machine and how it can benefit your business.

Introduction

Gutter Forming Machine is a kind of cold-forming equipment, which is often used in steel structure workshops, high-speed guardrails, color steel, and other industries. The steel that needs to be pressed will be sent to the forming processing part by the automatic feeding equipment, and the steel after forming will be automatically cut and then used for the roof or wall of warehouses, factories, gymnasiums, exhibition halls, and other buildings, so as to achieve a beautiful appearance and solid action. This equipment can make the processed products smooth, beautiful, and have uniform paint patterns, which is a piece of processing equipment favored by professional manufacturers.

Features

1. Gutter Forming Machine is designed with a PLC control system. Advanced mechanical automation software not only improves processing fastening but also improves the convenience of production information management.

2. The lubricating pump can provide lubricating oil to the non-moving parts of the friction when the machine is working, reducing the workload of manual maintenance.

3. Fine rotational molding has a good effect and can reduce the friction between the wheel and the raw material, which not only makes debugging more convenient, but also improves production efficiency.

4. The polished metal body is not only not easy to rust but also has good wear resistance, which can adapt to different production environments.

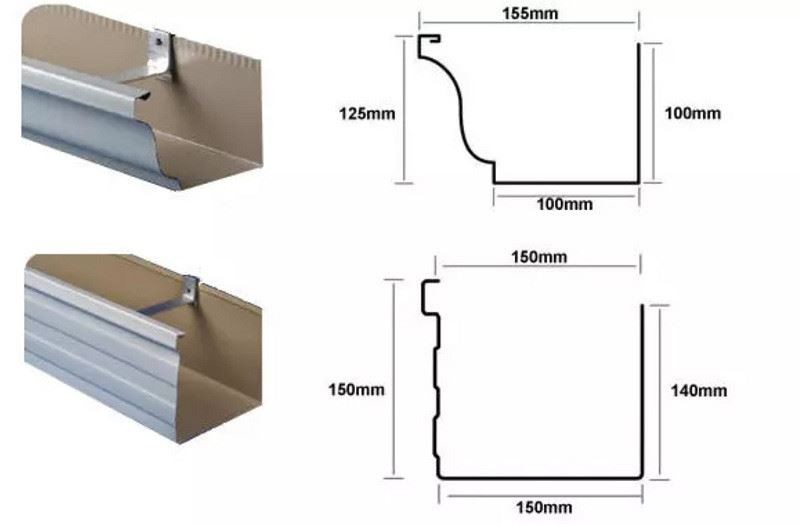

Profile Drawing

Process Drawing

|

Width of the material |

914mm/ 1000mm/ 1200mm/ 1220mm/ 1250mm |

|

Thickness of material |

0.3-0.8mm |

|

De-coiler |

Manual one, can load 5 tons of materia |

|

Rollers for forming |

16 station |

|

Diameter of the roller |

80mm |

|

Rolling material |

Carbon Steel 45# |

|

Main power |

5.5kw |

|

Material of the cutting blade |

Cr12 mov |

|

Hydraulic cutting power |

4kw |

|

Processing precision |

Within 1.00mm |

|

Control system |

Delta PLC control |

|

Side panel of machine |

16mm |

|

Main structure of the machine |

350 H steel |

|

Voltage |

380V 50Hz 3phases (changeable as needs) |

Why choose us?

- We provide a range of options for payment and shipment for your convenience when buying our Profile Forming Machines.

- Relying on its own technical strength and manufacturing experience, the company continues to be satisfied with the individual needs of customers to meet customer needs.

- Our Profile Forming Machines are not only superior in quality but also affordable.

- In order to enhance our competitiveness in the fierce market competition, we constantly pursue technological innovation and the pursuit of technological advancement.

- We can also provide customized services for different types of Profile Forming Machines to meet specific needs.

- We have established the service tenet of respect, honesty and innovation, and formed the team spirit of unity, hard work and pioneering.

- We're a reliable supplier and manufacturer of Profile Forming Machines, providing competitive prices.

- We are market-oriented and user-oriented, closely follow the market demand, closely follow the industry trend.

- The Profile Forming Machines we provide are known for their high efficiency, durability, and energy saving features.

- In the new development period, Gutter Forming Machine will continue to adhere to the innovation and research and development of core technologies, vigorously carry out Gutter Forming Machine, adhering to the corporate core values of ", , Diligence, and Peace", and "integrity, responsibility, hard work, and innovation". Enterprise spirit, realize Gutter Forming Machine dream together with customers.

Hot Tags: gutter forming machine, Floor Deck Roll Forming Machine, Steel Silo Rollformer, Closed Type Floor Decking Roll Forming Machine, Corrugated Roof Tile Forming Machine, CU Omega Purlin Roll Forming Machine, Beam Purlin Roll Forming Machine