Sheet Roll Forming

Description

Introduction:

As a manufacturer located in China, we are proud to present our Sheet Roll Forming product that has been designed to meet the needs of merchants who require quality products at a competitive price. Our Sheet Roll Forming product has been crafted with the latest technology and expertise to deliver the best results. With over [insert number of years] of experience in the industry, we have perfected our craft to provide products that are not only functional but also durable and long-lasting.

Features:

Our Sheet Roll Forming product features a number of incredible aspects that make it stand out from the rest. One of the most remarkable features is its ability to manufacture flat, uniform sheets from metal materials by rolling them through the machine. This revolutionary process ensures precision and accuracy, allowing for a consistent output every time. The product is also designed to accommodate a wide range of metals and thicknesses, making it the ideal solution for a variety of applications. Additionally, our Sheet Roll Forming product is constructed using only high-quality components that have been tested to ensure durability and reliability.

Benefits:

The benefits of our Sheet Roll Forming product are numerous, making it a valuable investment for any merchant looking to expand their business. Firstly, our product is incredibly cost-effective, allowing merchants to boost their profit margins without sacrificing quality. Secondly, the precision and accuracy of our Sheet Roll Forming product ensures consistent performance, resulting in less waste and scrapped materials. This translates to greater productivity and efficiency, which can save merchants time and money in the long run. Finally, our product is easy to install and operate, allowing for a smooth and seamless transition into any existing manufacturing process.

Applications:

Our Sheet Roll Forming product has a wide range of applications, making it the ideal solution for a variety of industries. Merchants can use our product to manufacture roofing and siding panels, automotive components, household appliances, and much more. The ability to produce custom designs and shapes means that merchants can cater to the unique needs of their customers, setting them apart from competitors in the market.

Conclusion:

In conclusion, our Sheet Roll Forming product is a top-of-the-line solution for merchants who require quality products at a competitive price. With its revolutionary technology, durability, and wide range of applications, it is a valuable investment that can help merchants boost their profitability, increase efficiency, and expand their business. We are confident that our Sheet Roll Forming product will exceed expectations and provide merchants with the tools they need to succeed in today’s competitive market.

Introduction

All kinds of production equipment in today's industrial production are constantly being upgraded, among which Sheet Roll Forming is a kind of equipment that is more popular with users. It is very suitable for the production and processing of metal roof panels, wall panels, and other materials. All kinds of popular corrugated boards, glazed tiles, and other materials can be roll-formed by this kind of equipment. It mainly uses the transmission mechanism to continuously transfer the material to the roller press unit for forming processing. Guiding devices, cutting devices, lubricating devices, etc. are all important components of it. Compared with the traditional process, it has high production efficiency, high product strength, and stable product quality, so it is very economical.

Features

1. Sheet Roll Forming mainly adopts a cold forging process, which is suitable for various materials, including stainless steel sheets, aluminum material, colored steel plates, etc.

2. The automated unit can precisely control the production and processing process, and the highly integrated network can also improve automation performance.

3. The simple operating system and control panel make it easier to adjust production information and parameters, and the accuracy of sheet metal forming can also be controlled.

4. Chrome-plated steel rollers are hard and not easily deformed. Good wear resistance makes it have a longer service life.

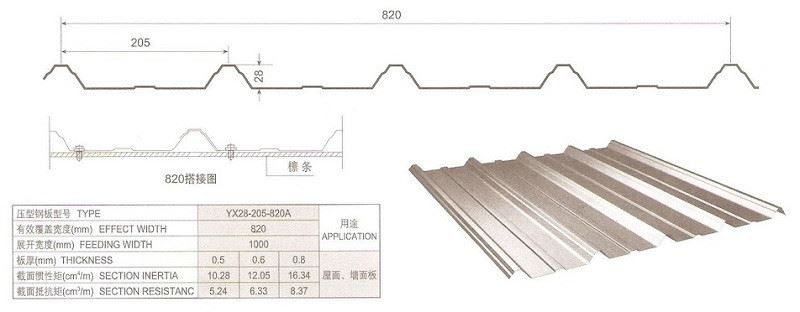

Profile Drawing

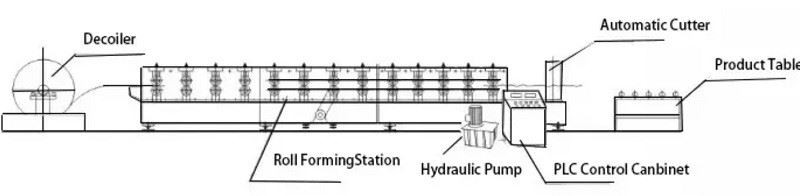

Process Drawing

|

Suitable materail |

PPGI/GI.0.3-1MM |

|

Coild width |

1000-1200 |

|

Material of machine frame |

400H steel structure. strong and durable |

|

Diameter of shaft |

70mm, high grade 45# steel |

|

Roller material |

High grade 45# steel, hard chromed 0.05-0.07mm |

|

Thickness of plate |

16mm |

|

Forming station |

16 |

|

Drive type |

By chain (1.0 inch), link bearing model 6210 |

|

Power of forming machine |

5.5kw |

|

Material of cutting blades |

Cr 12 mov, quenching 58-62℃ |

Why choose us?

- We offer a range of Profile Forming Machines with different processing capabilities, catering to different industries.

- What we pursue is to provide Sheet Roll Forming with world leading level and related quality services to our customers.

- We have invested heavily in research and development to produce innovative and efficient Profile Forming Machine products.

- Since its establishment, our company has established long-term cooperative relationships with many domestic companies. The product quality has been strictly inspected and recognized by all customers. All our staff thank all customers for their support and encouragement as always, and will adhere to the corporate tenet of "quality and service", and continue to serve new and old customers with enthusiasm!

- Our Profile Forming Machines are available for both small and large scale industrial applications.

- We are rapidly adapting to the changing environment, accelerating the transformation and restructuring, improving quality and efficiency, and upgrading, so that the company can maintain continuous profitable growth and capacity enhancement in the leading competitive fields and in the future business environment, and ensure the company's longevity.

- We offer a wide range of Profile Forming Machines in different models, designed to meet your specific needs.

- We are committed to become a first-class manufacturer and service provider, integrating various resources in the industry to provide the best quality solutions and services to our target customer groups.

- Our Profile Forming Machines are engineered to meet the changing demands of the manufacturing industry.

- We have always taken it as our responsibility to provide customers with quality Sheet Roll Forming and good services, and have received many awards from the community.

Hot Tags: sheet roll forming, Multi Rib Span Roof Sheet Roll Forming Machine, Metal Tile Sheet Making Machine, Roll Forming Machine IBR Making Machine, Corrugated Roof Sheeting Machine, Corrugated Barrel Type Machine, Steel Corrugated Sheet Roll Forming Machine