CU Omega Purlin Roll Forming

Description

The CU Omega Purlin Roll Forming system is an innovative and cost-effective solution for the construction and building industry. It is a high-quality, efficient and durable technology that creates consistent and accurate Omega Purlins, an essential component for supporting roofs, walls and floors.

Our roll forming system is manufactured using high-quality materials and advanced technology, ensuring that our customers receive a reliable, long-lasting, and precision machine. Our machinery can produce purlins in any number of lengths and sizes, making it ideal for customizing to specific project requirements.

The CU Omega Purlin Roll Forming system is made to work with various coil widths, thicknesses, and materials, including galvanized steel, aluminum, and stainless steel. It can work with varying speed to produce different types of purlins, including c-sections, z-sections, and floor deck profiles.

Our product has a user-friendly control system that is easy to operate, and maintenance of our machines is straightforward, which makes them an ideal option for those new to roll forming technology.

Our roll forming system has several other benefits that make it stand out from other solutions in the market. Firstly, our machines have a high level of automation, which makes them very efficient and accurate, resulting in consistent quality of purlins. Secondly, our machines have an excellent production capacity, which can handle large orders while minimizing lead times.

Thirdly, our roll forming machines have a low power consumption rate, which translates to lower operating costs over the long term. Additionally, our machines have a smart and efficient design, which makes them easy to install and integrate into existing production lines.

We take pride in offering high-quality machinery that is built to last, unlike many alternatives available in the market. Our machines are CE and ISO certified, which means they meet or exceed industry standards of quality and safety.

At CU Omega Purlin Roll Forming, we believe in offering our customers excellent service and support. We offer a comprehensive warranty and post-sales service to ensure our customers experience stress-free use of our machinery.

In conclusion, our CU Omega Purlin Roll Forming system is an efficient, reliable, and cost-effective solution for producing high-quality purlins for roofs, walls, and floors. Our machines are versatile, user-friendly, and operate with vast automation, making them a smart choice for all those looking to produce purlins with no compromise on quality.

Description

Purlins are horizontal elements distributed along the length of the roof that support the secondary rafters. Generally speaking, rural houses will use this kind of component more frequently. Cement purlins have a wider range of applications than wood and steel structures due to their durability and cost-effectiveness. CU Omega Purlin Roll Forming is exactly one type of equipment that can be used to produce this material, and it is a piece of equipment that is often used in machining activities in many modern factories. The finished products processed by it are of high quality, high strength, and not easy to deform. At the same time, the specifications of all finished products can also maintain a good consistency with few defects. At the same time, its structure is very stable, so there is no problem at high speed. And the simple structure not only makes it easy to operate but also easy to maintain. The lower noise also causes great damage to the operator. In addition, the PLC display of CU Omega Purlin Roll Forming also gives you a better grasp of the production process.

Features

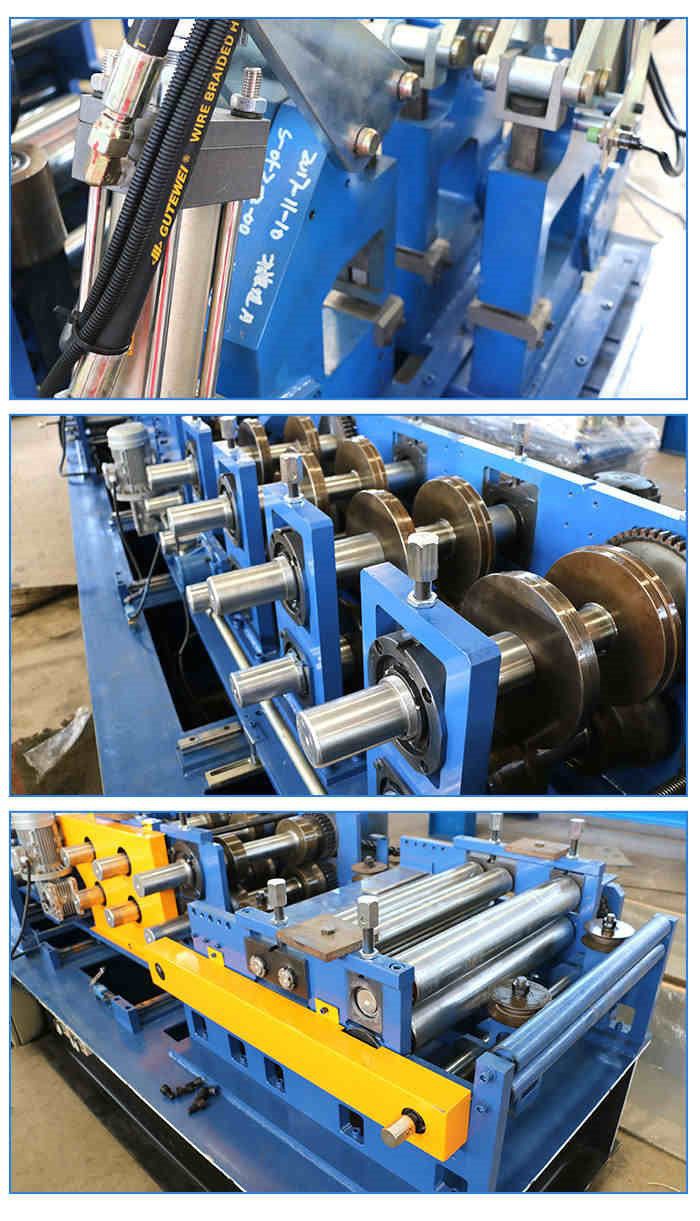

CU Omega Purlin Roll Forming is mainly composed of a rolling part, press, cutting machine, control system, and other parts.

The hydraulic pump operates with low noise and has a long service life.

You can choose from galvanized, color steel or aluminum coil, etc., they all have good corrosion resistance.

We can customize unique products for you to meet different production needs.

| Manual Un-coiler |

Max Capacity: 5000kgs |

|

Inner diameter of coil: 400-600mm |

|

|

Manual with brake |

|

|

Leveling Device |

Ensure the material level and straight |

|

The width can be adjusted |

|

|

Main Forming System |

Width & Height & Thickness of sheet: According to Drawings |

|

Material: GI sheet coil or Colored sheet coil |

|

|

Motor Power: 7.5 kw forming system |

|

|

Roller material: Cr12 |

|

|

Surface of Roller: Heat treatment HRC 58-60 |

|

|

Diameter of main shaft: 60mm #45 steel, heat treat modulation |

|

|

Forming station: 12 stations. |

|

|

Transmission: by chain and gear |

|

|

Measuring accuracy: +/- 0.5 mm/M. |

|

|

Arch middle plate: 30mm thickness. |

|

|

Output: 8-10 Tons per shift (8 hrs.). |

|

|

The machine base is assembled and welded by high quality steel. |

|

|

Cutting way: Tracking. |

|

|

Oil pump station: 1set |

|

|

Motor power of Oil pump station: 5.5kw with cooling system |

|

|

Forced air cooling device available. |

|

|

Cutting mould: 1 sets |

|

|

Material of blade: Cr12 with heat treatment HRC60-62. |

|

|

Electrical System |

Control system: HMI & PLC control panel |

|

Power: 380V 50Hz (as per local requirement) |

|

|

Run-out Table |

Frame: A3 |

|

Roller type |

|

|

Quantity: 1 pc |

Why choose us?

- We offer comprehensive training and support to ensure customers can effectively operate our machines.

- We respect, understand and care for people, provide them with a broad space for development and build a platform for their progress.

- Our machines are versatile and can be used to produce a wide range of products.

- We will make full use of our technological advantages to build a new environmental protection industry with first-class technology, first-class management and first-class efficiency.

- Our metal roll forming machines are designed to be highly productive and cost-effective.

- We have advanced production equipment and experienced management and design talents, and have won the praise of our customers with fast delivery time and professional service level.

- We specialize in producing Metal Roll Forming Machines of the highest quality.

- We firmly believe that good faith is the premise of the company's operation, good quality is the basis of the market, professional talents are the life of the development company, and mutual benefit and win-win can make our cooperation for a long time.

- We have a proven track record of delivering high-quality metal roll forming machines to customers worldwide.

- We persistently pursue scientific and technological innovation to upgrade our CU Omega Purlin Roll Forming in order to gain a place in the fierce market competition.

Hot Tags: cu omega purlin roll forming, Profile Forming Machine, Rolling Shutter Making Machine, Shape Roll Forming Machine, Corrugated Forming Machine, Metal Roll Former, Steel Water Tank Making Machine