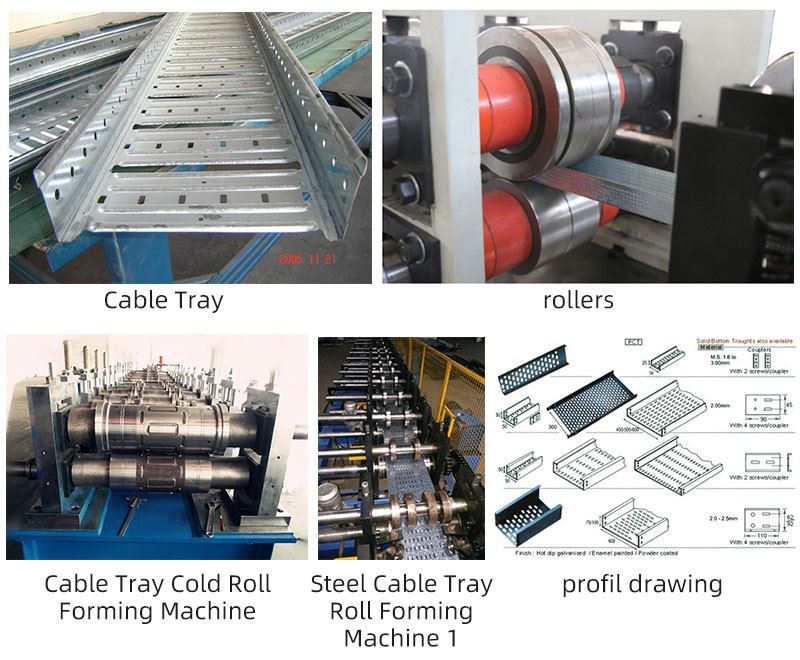

Cable Tray Roll Forming Machine

Description

Introducing our Cable Tray Roll Forming Machine - The Ultimate Solution for Cable Management

Cable management is one of the most important aspects of construction and industrial projects. The proper handling of cables not only ensures safety and efficiency but also helps to maintain a clean and organized working environment. For this reason, the demand for reliable and innovative cable tray solutions is constantly increasing all around the world.

As a leading manufacturer located in China, we have developed a state-of-the-art Cable Tray Roll Forming Machine that can transform the way you manage your cables. With over 10 years of experience in the industry, we have gained a reputation for producing high-quality and high-performance products that meet the expectations of customers worldwide.

What Is a Cable Tray Roll Forming Machine?

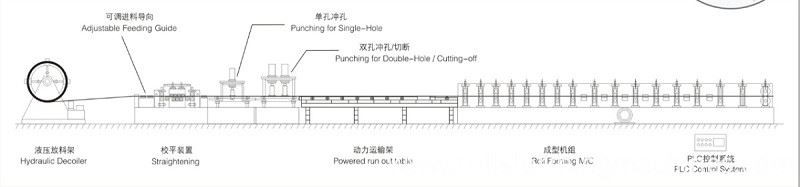

A Cable Tray Roll Forming Machine is an advanced piece of equipment that is designed to produce high-quality cable trays with consistent accuracy and precision. The machine consists of several components, including a decoiler, leveling machine, punching system, forming rollers, cutting system, and a control system.

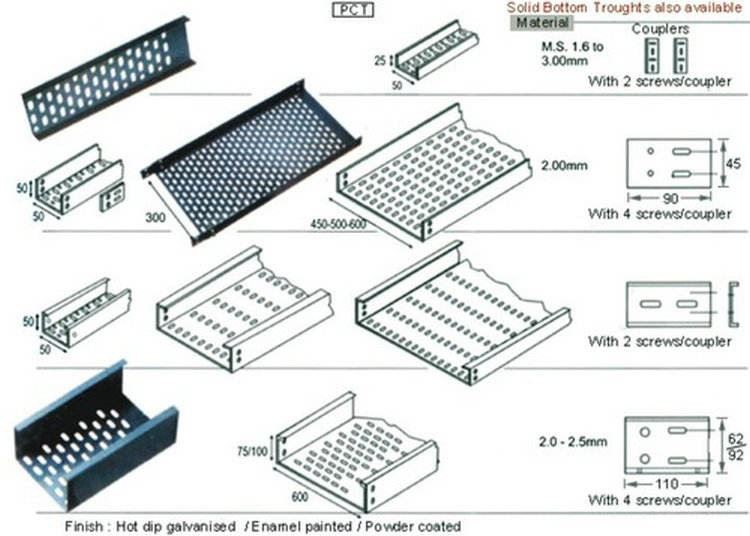

Our Cable Tray Roll Forming Machine is engineered to create cable trays of various shapes and sizes, including ladder-type, perforated, solid bottom, and wire mesh. With its efficient production process, the machine can produce a large number of cable trays in a short amount of time, enabling you to meet the increasing demands of your clients.

Benefits of Using Our Cable Tray Roll Forming Machine

1. High Efficiency and Productivity

Our Cable Tray Roll Forming Machine is designed to increase your production efficiency and productivity, allowing you to fulfil customer orders quickly and efficiently. With its automatic cutting and punching system, you can produce high-quality cable trays with consistent accuracy and precision.

2. Cost-Effective Solution

By using our Cable Tray Roll Forming Machine, you can reduce labor costs and minimize the waste of materials, resulting in cost savings for your business. Moreover, the machine's production process requires minimal human intervention, reducing the chances of errors and increasing the overall quality of the final product.

3. Wide Range of Applications

Our Cable Tray Roll Forming Machine is suitable for a wide range of applications, including construction, engineering, and industrial projects. The cable trays produced by the machine can accommodate various cable types, sizes, and shapes, ensuring a versatile and adaptable solution for your cable management needs.

4. Customizable Options

We understand that different customers have different requirements when it comes to cable management solutions. For this reason, we offer customizable options to our Cable Tray Roll Forming Machine, such as changing the tray width or adding specific features, ensuring that the machine is suitable for your specific needs.

5. High-Quality and Durable

Our Cable Tray Roll Forming Machine is made of only high-quality and durable materials, ensuring its longevity and reliability. The machine has a sturdy and robust structure, can withstand high-intensity usage, and requires low maintenance, making it an excellent long-term investment for your business.

Conclusion

When it comes to efficient and reliable cable management solutions, nothing beats the Cable Tray Roll Forming Machine. Our product is a cost-effective and high-quality solution that can help you meet the ever-increasing demands of your customers. With its advanced features, customizable options, and versatile applications, our machine is a must-have equipment for any construction, engineering, or industrial project. Contact us today to learn more about our Cable Tray Roll Forming Machine and how it can transform the way you manage your cables.

Introduction

This cable tray roll forming machine is characterized by strong productivity, high precision, wide application range and good flexibility. It is the perfect solution to help customers improve production efficiency while reducing material waste. This machine is made of high-quality raw materials, and its structure has been scientifically and reasonably arranged to ensure long-lasting stability. The main components such as the uncoiler, leveling machine, punching system, and forming roller all have high quality and good durability, aiming to help customers produce consistent and high-precision final products. This machine can mass produce cable tray in a short time to help customers increase economic benefits. If you have any questions about this product, please feel free to contact us at any time.

Features

1. This molding machine adopts a cantilever design on both sides, and the punch presses and cuts the circular ribs of the bottom or different holes.

2. The material is guided into the main roller forming machine by a guide. Through electrical control, this machine can automatically improve and adjust different widths and heights.

3. This machine can effectively reduce the labor intensity of workers, thereby saving production costs, as it is equipped with an easy to operate control system.

4. We will provide professional staff to guide customers on any technical issues related to this cable tray roll forming machine. The operation manual will be attached.

Main components

| Automatic inner tight decoiler |

1. Coil inner diameter 450mm-550mm |

|

2. Maximum width of coiling 600mm |

|

|

3. Maximum weight of loading 2500kg |

|

|

Main forming machine |

1. Forming stations: 11rows |

|

2. Material of shaft: 45# steel. Outer diameter 60mm |

|

|

3. Main motor power: 5.5kw |

|

|

4. The speed of forming: 0-50m/min |

|

|

Hydraulic cutter |

1. Material of blade: Cr12 mould steel with quenched treatment 60-62 |

|

2. Cutting system: adopt advanced hydraulic drive, after forming automatic cut, no distort, no wasting , high safe factor. (tracking cutting) |

|

|

The electrical control system |

1. The Brand of display: DELTA |

|

2. The main computer (PLC): DELTA DVP14 |

|

|

Hydraulic system |

1. Adopting advanced hydraulic system of Tai Wan |

|

2. Power: 3kw |

Profile Drawin

Process Drawing

Why choose us?

- Our machines are versatile and can be used to produce a wide range of products.

- Our business processes are standardized, institutionalized and simplified for the convenience of our customers.

- We provide excellent after-sales service to ensure customer satisfaction.

- We try our best to let our customers use our Cable Tray Roll Forming Machine more safely. We always hope to achieve the fundamental purpose of mutual benefit and let our customers have a more satisfactory evaluation of our service.

- We have a reliable and efficient supply chain, ensuring timely delivery of our products.

- We are committed to providing professional, sincere and effective services for customers' market effect, brand value promotion and brand value accumulation.

- Our machines are designed with safety in mind, ensuring a safe and secure work environment.

- Our quality is the capital of our survival. We strictly require that every person, every link of production, every process should be supervised by professionals. Finally, each Cable Tray Roll Forming Machine should be inspected. We do shipment is all good products.

- We continuously strive to improve our products and services to meet the evolving needs of our customers.

- Research and development and manufacture of high-quality Cable Tray Roll Forming Machine is our work, the creation and operation of the first brand is our goal, sincerely win customers with high-quality products and excellent service to expand product sales is our goal.

Hot Tags: cable tray roll forming machine, Forming Machine, Steel Water Tank Rollformer, Steel Frame Rollformer, Shutter Door Roll Forming Machine, Cable Tray Roll Forming Machine, Metal Rollfomer